To be precise, a batch reactor has no single, standard capacity. Its size is dictated entirely by its intended application, ranging from small glass flasks of a few milliliters in a research lab to massive, industrial-scale steel vessels that can hold over 20,000 liters (approximately 5,300 gallons). The critical factor is not just the physical volume but the overall throughput a given reactor can achieve in a production cycle.

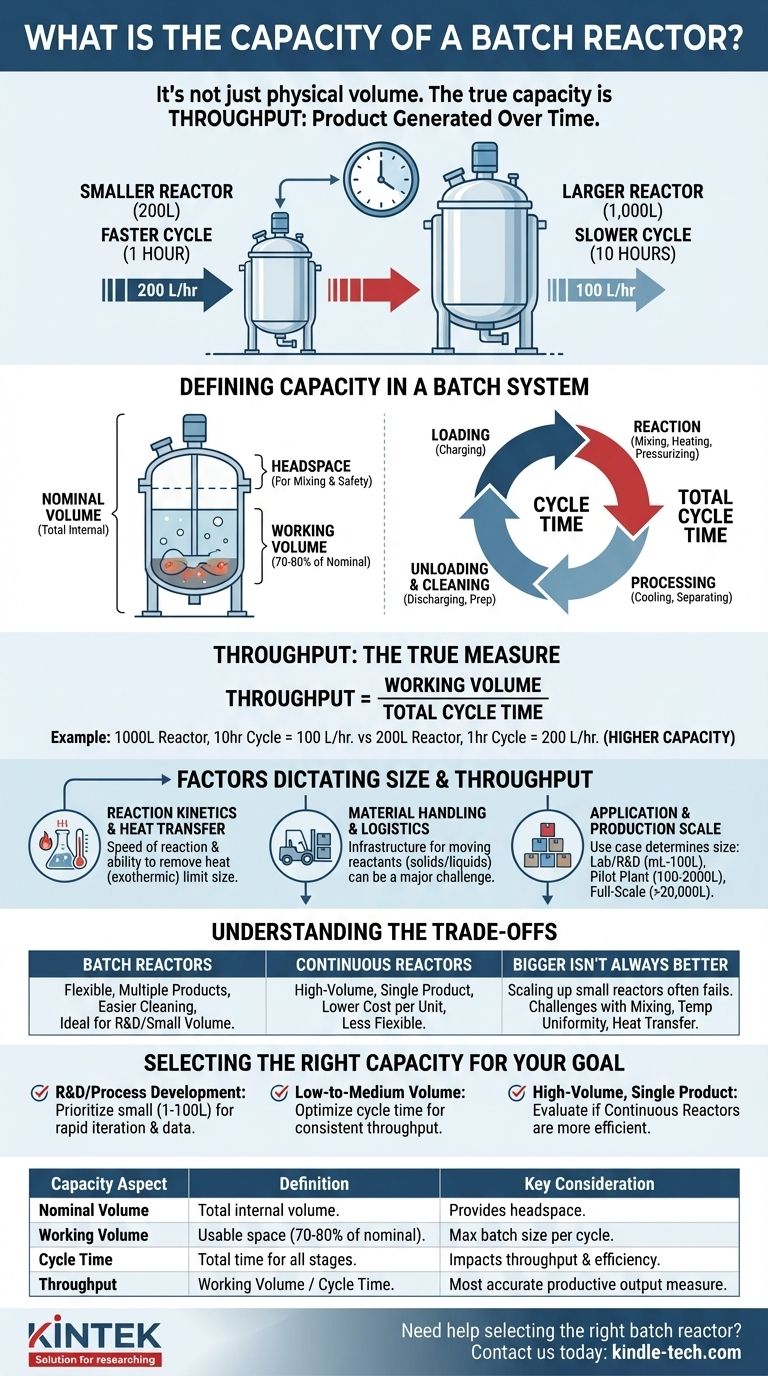

The true "capacity" of a batch reactor is not its physical volume, but its throughput—the amount of product it can generate over time. This is a function of its working volume combined with the total time required for loading, reaction, cooling, and unloading.

Defining "Capacity" in a Batch System

Thinking about batch reactor capacity requires moving beyond a simple volume measurement. The operational cycle is what truly defines its productive output.

Nominal vs. Working Volume

A reactor's nominal volume is its total internal volume, but this is never fully utilized. The working volume, typically 70-80% of the nominal volume, is the actual space available for the reactants. This headspace is essential to accommodate mixing, foaming, or pressure changes during the reaction.

The Critical Role of Cycle Time

The defining characteristic of a batch reactor is its non-continuous operation. The total cycle time includes every step:

- Loading: Charging the vessel with reactants.

- Reaction: Heating, pressurizing, and mixing for the required duration.

- Processing: Cooling, depressurizing, and product separation.

- Unloading & Cleaning: Discharging the product and preparing for the next batch.

A fast reaction in a large vessel is meaningless if the heating, cooling, and cleaning steps take an entire day.

Throughput: The True Measure of Capacity

The most accurate measure of a batch reactor's capacity is its throughput, calculated as: (Working Volume) / (Total Cycle Time).

For example, a 1,000-liter reactor with a 10-hour cycle time has an effective throughput of 100 liters per hour. A smaller, 200-liter reactor with a more efficient 1-hour cycle time achieves a throughput of 200 liters per hour, making it the higher-capacity option in practice.

Factors That Dictate Reactor Size and Throughput

The optimal size and design of a batch reactor are a result of balancing several key engineering and logistical factors.

Reaction Kinetics and Heat Transfer

The speed of the chemical reaction (kinetics) is a primary constraint. For reactions that generate significant heat (exothermic), the reactor's ability to remove that heat becomes the limiting factor. A vessel that is too large may develop dangerous "hot spots" if its surface-area-to-volume ratio is too low for effective cooling.

Material Handling and Logistics

The physical reality of moving materials is a major consideration. While a 50,000-liter reactor is theoretically possible, the infrastructure required to load tons of solid feedstock (like in a pyrolysis system) or safely handle vast quantities of liquids becomes a significant challenge.

Application and Production Scale

The intended use case is the ultimate determinant.

- Laboratory/R&D: Focuses on flexibility and data collection. Capacities are small, from milliliters to ~100 liters.

- Pilot Plant: Used to prove a process at scale. Capacities typically range from 100 to 2,000 liters.

- Full-Scale Production: Designed for efficiency. Capacities can exceed 20,000 liters, but this is where batch systems begin to compete with continuous reactors.

Understanding the Trade-offs

Choosing a batch reactor involves accepting a specific set of operational compromises. Understanding these is crucial for making an informed decision.

Batch vs. Continuous Reactors

Batch reactors offer excellent flexibility. They can be used for multiple products, are easier to clean between runs, and are ideal for smaller production volumes or R&D.

Continuous reactors (like a CSTR or PFR) are built for one purpose: high-volume, steady-state production of a single product. They offer lower operational costs per unit of product but lack the flexibility of a batch system.

The Pitfall of "Bigger is Better"

Simply scaling up a small batch reactor often leads to failure. A process that works in a 10-liter flask may not work in a 1,000-liter vessel because of challenges with mixing effectiveness, temperature uniformity, and heat transfer. Each tenfold increase in volume requires a complete re-evaluation of the engineering design.

Operational Costs and Labor

Batch processing is inherently start-and-stop, which often requires more direct operator intervention for loading, monitoring, and unloading. This can lead to higher labor costs compared to a highly automated continuous process.

Selecting the Right Batch Capacity for Your Goal

Base your decision on your primary operational objective, not just a desired volume.

- If your primary focus is R&D or process development: Prioritize smaller, more manageable reactors (1-100 L) that allow for rapid iteration and data collection.

- If your primary focus is dedicated, low-to-medium volume production: Select a reactor size where the entire cycle time is optimized and predictable, ensuring consistent throughput.

- If your primary focus is high-volume, single-product manufacturing: Critically evaluate whether a continuous reactor system would provide a more efficient and cost-effective solution than a very large batch reactor.

Ultimately, choosing the right capacity means understanding that a batch reactor's performance is measured in output over time, not just its size.

Summary Table:

| Capacity Aspect | Definition | Key Consideration |

|---|---|---|

| Nominal Volume | Total internal volume of the reactor. | Not fully utilized; provides headspace for safety. |

| Working Volume | Usable space for reactants (typically 70-80% of nominal volume). | Dictates the maximum batch size per cycle. |

| Cycle Time | Total time for loading, reaction, processing, and unloading. | Directly impacts throughput and operational efficiency. |

| Throughput | True capacity: Working Volume / Cycle Time. | The most accurate measure of a reactor's productive output. |

Need help selecting the right batch reactor for your lab or production scale?

Choosing the correct reactor capacity is critical for optimizing your process efficiency and output. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific laboratory needs. Whether you're in R&D, pilot plant testing, or full-scale production, our experts can help you find a batch reactor solution that maximizes your throughput and fits your operational goals.

Contact us today to discuss your requirements and discover how KINTEK can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- Why is a High-temperature and High-pressure Autoclave necessary for zirconium alloy testing? Ensure Nuclear Safety.

- What is the role of a high-pressure reactor in h-BN magnetic nanocomposite synthesis? Master Precision Deposition

- What environment does a PTFE-lined autoclave provide for TiO2-GQD synthesis? Achieve Superior Nanocomposite Results

- What is the significance of the hydrothermal environment in HA preparation? Optimize Mesoporous Structure and Purity

- What is the function of a high-pressure static autoclave in biomass HTL? Optimize Your Biomass Conversion Research