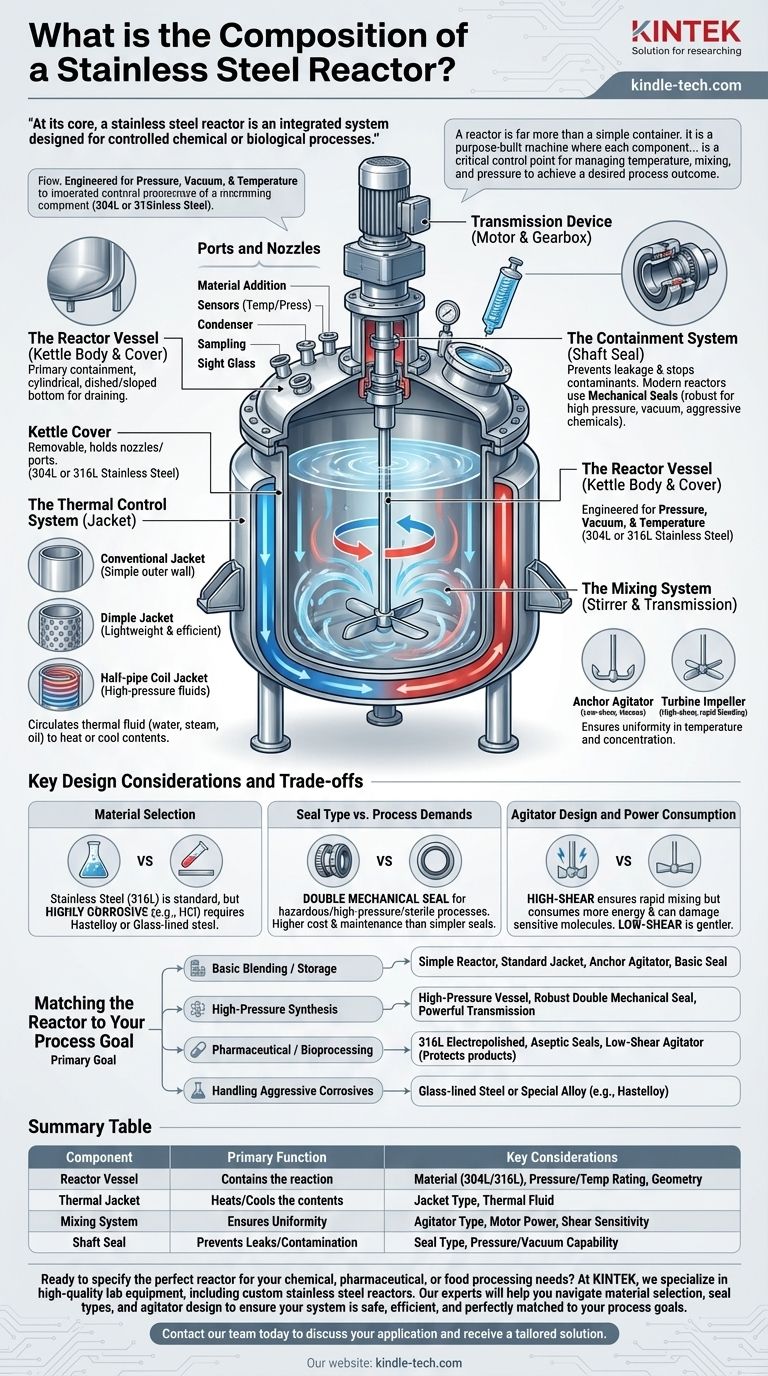

At its core, a stainless steel reactor is an integrated system designed for controlled chemical or biological processes. Its primary components include the main vessel (kettle body and cover), a thermal control jacket, a mixing system (stirrer and transmission), and a shaft sealing device to ensure containment. These parts work in concert to create a precise, repeatable environment.

A reactor is far more than a simple container. It is a purpose-built machine where each component—from the seal to the stirrer—is a critical control point for managing temperature, mixing, and pressure to achieve a desired process outcome.

The Anatomy of a Stainless Steel Reactor

Understanding a reactor means understanding the function of each core component. While designs vary, a standard configuration serves as the foundation for most chemical, pharmaceutical, and food processing applications.

The Reactor Vessel (Kettle Body & Cover)

The kettle body is the primary containment vessel where the reaction takes place. It is typically cylindrical with a dished or sloped bottom to facilitate draining.

The kettle cover seals the top of the vessel and is removable for cleaning and maintenance. It holds the various nozzles and ports for instrumentation and material transfer.

Together, the body and cover are engineered to withstand the specific pressure, vacuum, and temperature requirements of the process. The choice of stainless steel (commonly 304L or 316L) provides excellent corrosion resistance and cleanability.

The Thermal Control System (Jacket)

Most reactors are wrapped in a jacket, which is an outer shell that creates a cavity around the main vessel.

A thermal fluid, such as water, steam, or oil, is circulated through this jacket to heat or cool the vessel's contents. This is the primary mechanism for controlling reaction temperature.

Common jacket types include conventional jackets (a simple outer wall), dimple jackets (lightweight and efficient), and half-pipe coil jackets (for high-pressure thermal fluids).

The Mixing System (Stirrer & Transmission)

The stirrer, also known as an agitator, is a shaft with impellers that extends into the vessel. Its purpose is to mix the contents to ensure uniformity in temperature and concentration, which is critical for reaction speed and product quality.

The transmission device, consisting of a motor and gearbox, provides the power and controls the rotational speed of the stirrer.

Stirrer designs vary widely based on the application, from low-shear anchor agitators for viscous products to high-shear turbine impellers for rapid blending.

The Containment System (Shaft Seal)

The shaft seal is a critical component located where the stirrer shaft enters the reactor cover. Its job is to prevent leakage of the vessel's contents and to stop contaminants from entering.

Modern reactors almost exclusively use mechanical seals, which are robust devices capable of handling high pressures, vacuums, and aggressive chemicals without leaking. Simpler packing seals may be used in less demanding applications.

Ports and Nozzles

The reactor cover is equipped with multiple nozzles. These are connection points for adding raw materials, installing sensors (temperature, pressure), attaching a condenser, taking samples, or adding a sight glass for visual monitoring.

Key Design Considerations and Trade-offs

Choosing a reactor involves balancing performance, cost, and process safety. The "best" design is always relative to the specific chemical process it will serve.

Material Selection: Why Stainless Steel Isn't Always Enough

Stainless steel (especially 316L) is the industry workhorse due to its excellent corrosion resistance, strength, and ease of cleaning.

However, it has limitations. Highly corrosive chemicals like concentrated hydrochloric acid will attack stainless steel. In these cases, more exotic materials like Hastelloy or a glass-lined steel reactor are required, which significantly increases cost.

Seal Type vs. Process Demands

A robust double mechanical seal provides the highest level of containment, which is essential for hazardous materials, high-pressure reactions, or sterile processes.

The trade-off is higher initial cost and maintenance complexity compared to simpler packing or single mechanical seals. Choosing an inadequate seal is a major safety and operational risk.

Agitator Design and Power Consumption

An aggressive, high-shear agitator ensures rapid mixing but consumes more energy and can damage sensitive molecules (e.g., in bioprocessing).

A low-shear agitator is gentler and more energy-efficient but may be insufficient for thick slurries or reactions that require intense mixing. The design must be matched to the viscosity and sensitivity of the product.

Matching the Reactor to Your Process Goal

The ideal reactor configuration depends entirely on your specific objective. Use your primary goal to guide your specifications.

- If your primary focus is basic blending or storage: A simple reactor with a standard jacket, anchor agitator, and a basic mechanical seal is often sufficient.

- If your primary focus is high-pressure synthesis: Your priority is a vessel with a high-pressure rating, a robust double mechanical seal, and a powerful transmission system.

- If your primary focus is pharmaceutical or bioprocessing: You need a 316L stainless steel reactor with highly polished surfaces (electropolished), aseptic (sterile) seals, and a low-shear agitator to protect sensitive products.

- If your primary focus is handling aggressive corrosives: The material is your first concern; you must specify glass-lined steel or a special alloy like Hastelloy instead of standard stainless steel.

By understanding how these fundamental components function and interact, you can specify a reactor system that is safe, efficient, and perfectly suited to your process needs.

Summary Table:

| Component | Primary Function | Key Considerations |

|---|---|---|

| Reactor Vessel | Contains the reaction | Material (304L/316L), pressure/temperature rating, geometry |

| Thermal Jacket | Heats/cools the contents | Jacket type (conventional, dimple, half-pipe), thermal fluid |

| Mixing System | Ensures uniformity | Agitator type (anchor, turbine), motor power, shear sensitivity |

| Shaft Seal | Prevents leaks and contamination | Seal type (mechanical, packing), pressure/vacuum capability |

Ready to specify the perfect reactor for your chemical, pharmaceutical, or food processing needs?

At KINTEK, we specialize in high-quality lab equipment, including custom stainless steel reactors. Our experts will help you navigate material selection, seal types, and agitator design to ensure your system is safe, efficient, and perfectly matched to your process goals—whether you require basic blending, high-pressure synthesis, or sterile bioprocessing.

Contact our team today to discuss your application and receive a tailored solution.

Visual Guide

Related Products

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis

- What role does a high-temperature and high-pressure reactor play in CoFe2O4/Fe synthesis? Unlock Core-Shell Precision

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- Why is a reactor equipped with a reflux condenser required when studying the effects of temperature on niobium adsorption?