The fundamental difference is that "121" and "134" refer to the two standard sterilization temperatures used in autoclaves, measured in degrees Celsius. A 121°C cycle is the universal standard for general-purpose sterilization, requiring a longer time to be effective. In contrast, a 134°C cycle is a higher-temperature, higher-pressure process used to sterilize heat-resistant materials like metal instruments much more quickly.

The choice between a 121°C and 134°C cycle is not about the autoclave itself, but about the material you are sterilizing and the speed you require. The temperature is a setting, and the right choice depends entirely on balancing material compatibility with operational efficiency.

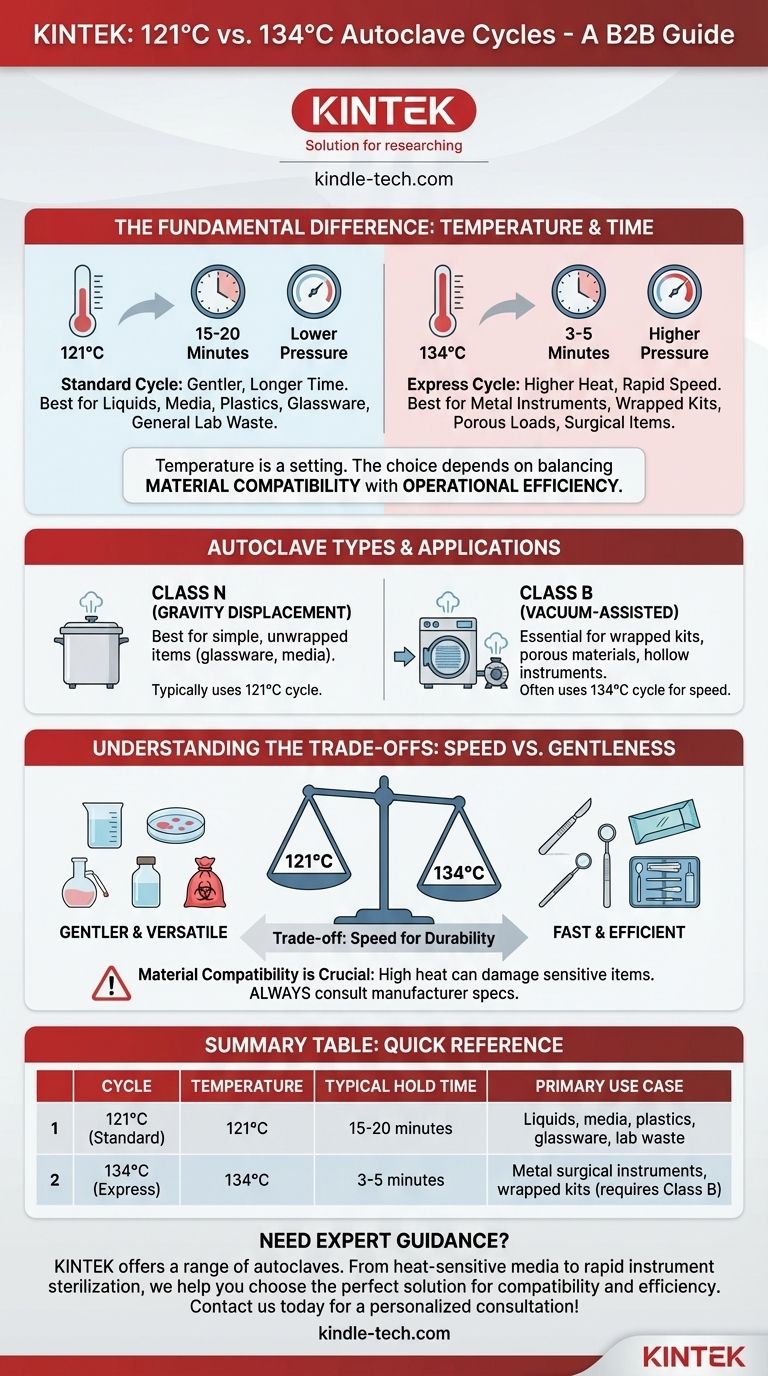

The Core Difference: Temperature, Time, and Pressure

The effectiveness of steam sterilization depends on a precise relationship between temperature, pressure, and time. Changing one variable requires adjusting the others to achieve the complete destruction of all microorganisms.

The 121°C Standard Cycle

This is the workhorse of sterilization, particularly in research and laboratory settings. It operates at a lower temperature and requires a longer holding time to ensure sterility.

It is the ideal choice for sterilizing liquids, media, plastics, glassware, and general lab waste. The typical holding time at 121°C is 15 to 20 minutes, once the target temperature is reached.

The 134°C Express Cycle

This cycle is primarily used in medical and dental fields where speed and throughput are critical. The significantly higher temperature drastically reduces the required sterilization time.

This is best for robust, heat-resistant items like metal surgical instruments. The typical holding time at 134°C is only 3 to 5 minutes, making it highly efficient for clinical use.

How Temperature Connects to Autoclave Type

While most modern autoclaves can run cycles at both temperatures, the type of autoclave often reflects its primary intended use and the cycles it is optimized for.

Simple Gravity Displacement Autoclaves (Class N)

These are the most basic autoclaves, often found in labs. They introduce steam at the top, which displaces the heavier, cooler air downwards and out through a vent.

Because they don't have a vacuum pump to actively remove air, they are best suited for simple, unwrapped items like glassware or media. The 121°C cycle is most common for these applications.

Vacuum-Assisted Autoclaves (Class B)

These more advanced machines use a vacuum pump to remove air from the chamber before steam is injected. This process, called pre-vacuum, is critical for ensuring steam penetrates complex loads.

Class B autoclaves are essential for sterilizing porous materials (like surgical gowns), hollow instruments, and wrapped kits. The rapid 134°C cycle is frequently used with these machines to quickly prepare instruments for use.

Understanding the Trade-offs

Choosing the wrong temperature can lead to ineffective sterilization or damaged equipment. The decision requires careful consideration of the items being processed.

Material Compatibility is Crucial

The high heat of a 134°C cycle can melt certain plastics, damage sensitive electronics, or degrade rubber seals that would be perfectly safe at 121°C.

Always consult the manufacturer's specifications for any instrument or material before autoclaving it at a higher temperature.

Speed vs. Gentleness

The primary trade-off is clear: speed for durability. The 134°C cycle offers immense speed, which is critical in a busy clinic or hospital.

The 121°C cycle is gentler and offers broader material compatibility, making it the safer, more versatile choice for a mixed-use research environment.

The Goal is Always Sterility

Both temperatures achieve complete sterilization when used with the correct holding time and for the appropriate materials. One is not "better" than the other; they are simply tools for different jobs.

Making the Right Choice for Your Goal

To select the correct cycle, start by identifying your primary objective.

- If your primary focus is sterilizing laboratory media, liquids, or glassware: Use the standard 121°C cycle to ensure compatibility and effectiveness.

- If your primary focus is rapidly sterilizing unwrapped, solid metal instruments: Use the 134°C cycle to maximize speed and throughput.

- If your primary focus is sterilizing wrapped instrument kits or porous loads: Use a 134°C cycle within a Class B (pre-vacuum) autoclave to ensure complete steam penetration.

- If your primary focus is sterilizing heat-sensitive plastics or complex devices: Default to the gentler 121°C cycle after verifying the item's heat tolerance with the manufacturer.

Ultimately, selecting the correct sterilization temperature is a critical decision based on your material's tolerance and your operational needs.

Summary Table:

| Cycle | Temperature | Typical Hold Time | Primary Use Case |

|---|---|---|---|

| 121°C (Standard) | 121°C | 15-20 minutes | Liquids, media, plastics, glassware, lab waste |

| 134°C (Express) | 134°C | 3-5 minutes | Metal surgical instruments, wrapped kits (requires Class B autoclave) |

Need expert guidance on selecting the right autoclave for your specific sterilization needs? KINTEK specializes in laboratory equipment and consumables, offering a range of autoclaves from basic gravity displacement to advanced pre-vacuum models. Whether you're processing heat-sensitive lab media or require rapid sterilization for clinical instruments, our team can help you choose the perfect solution for material compatibility and operational efficiency. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the maximum temperature range for an autoclave? Achieve Guaranteed Sterilization

- Why is it important that high temperatures are used in sterilisation? Ensure Complete Microbial Destruction

- How often do autoclaves need to be serviced? A Guide to Risk-Based Maintenance Schedules

- Why is a laboratory autoclave necessary for Postgate Medium B (PMB)? Ensure Pure SRB Cultures & Accurate MIC Research

- What is the recommended inspection frequency for laboratory autoclaves? Expert Maintenance Protocols for Safe Operation

- In what industries and applications are steam sterilizers or autoclaves used? Discover Key Uses Across 4 Major Sectors

- What are the standard conditions for sterilization of equipment contaminated with blood by autoclaving? Ensure Complete Sterility & Safety

- Is a UV sterilizer as good as an autoclave? The Critical Difference Between Sterilization and Disinfection