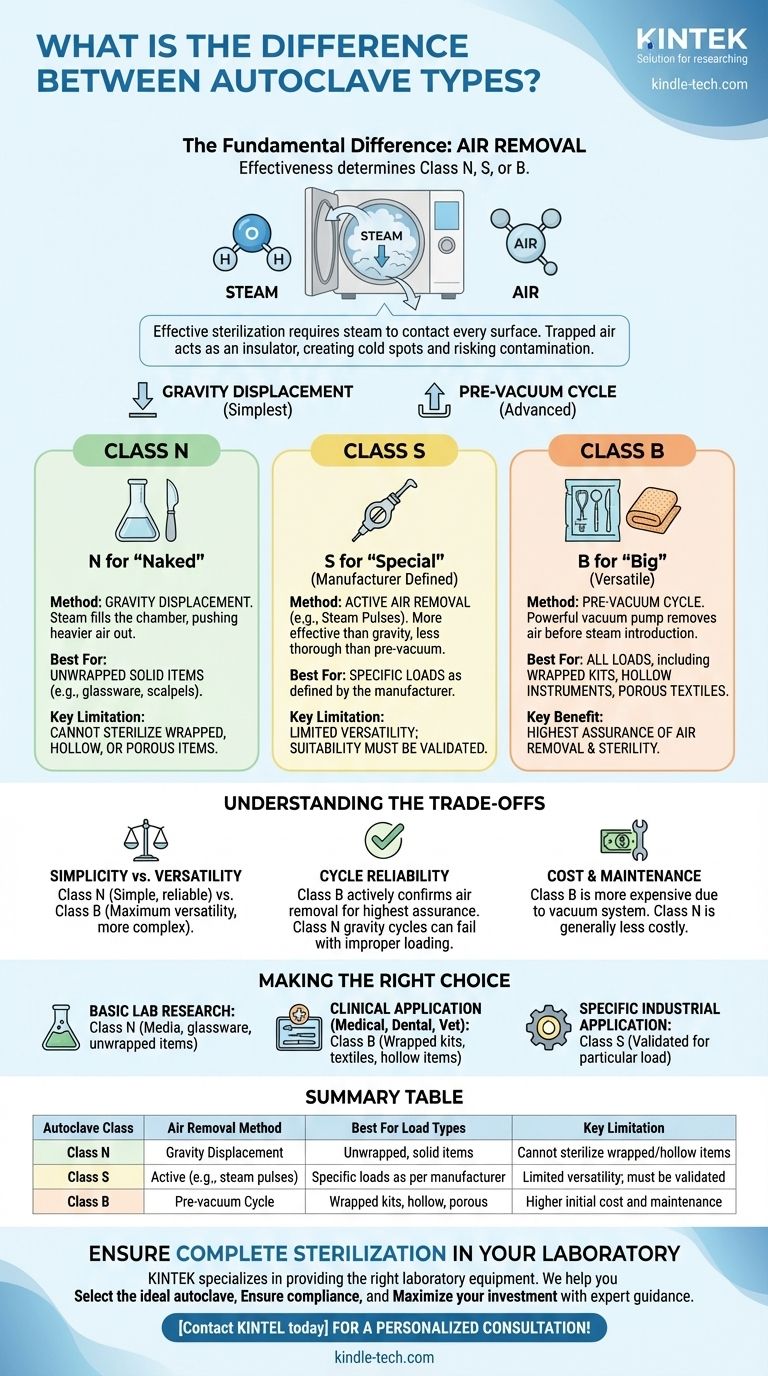

The fundamental difference between autoclave types lies in how effectively they remove air from the sterilization chamber. While they vary in size and operation, their classification into Class N, Class S, and Class B is determined by the method of air removal, which dictates the types of materials they can safely sterilize.

The critical distinction is not size or appearance, but the mechanism used to replace air with steam. An autoclave's ability to sterilize complex items like wrapped instruments or porous textiles depends entirely on its method for removing insulating air pockets.

The Core Principle: Why Air Removal is Critical

Effective sterilization requires saturated steam to make direct contact with every surface of the load. Air is a poor conductor of heat and acts as an insulator, preventing steam from reaching and sterilizing items.

The Problem of Trapped Air

If air is not completely removed from the chamber and the load, it creates "cold spots." These are areas where the temperature does not reach the required level for sterilization, leading to a failed cycle and a significant risk of contamination.

Two Solutions for Air Removal

Autoclaves solve this problem in two primary ways. The simplest method relies on gravity, while more advanced systems use a vacuum pump for active air removal. These methods define the different classes of autoclaves.

The Three Classes of Autoclaves

The most widely accepted classification system sorts autoclaves into three types, each suited for different sterilization loads.

Class N Autoclaves

This is the most basic type of autoclave. The 'N' stands for "naked," referring to the unwrapped solid items it is designed to sterilize.

Class N autoclaves use a gravity displacement method. Steam is pumped into the chamber, and because it is less dense than air, it fills the top and pushes the colder, heavier air out through a port at the bottom. This method is only effective for simple, solid objects like glassware or scalpels.

Class B Autoclaves

This is the most advanced and versatile type of autoclave. The 'B' stands for "big," referring to its ability to handle the widest range of sterilization loads.

Class B autoclaves use a pre-vacuum cycle. Before introducing steam, a powerful vacuum pump actively removes air from the chamber. This process ensures there are no trapped air pockets, allowing steam to penetrate complex loads like porous materials (gowns, dressings), hollow instruments (tubes, dental handpieces), and wrapped surgical kits.

Class S Autoclaves

This class represents a middle ground between N and B. The 'S' stands for "special," as these autoclaves are designed for specific loads as defined by the manufacturer.

Class S autoclaves employ an active method of air removal that is more effective than gravity but may not be as thorough as a Class B vacuum pump. This often involves a series of steam flushes and pressure pulses to push air out. Their suitability depends entirely on the specific instruments you need to sterilize.

Understanding the Trade-offs

Choosing an autoclave involves balancing capability against complexity and cost. Each class presents a distinct set of advantages and limitations.

Simplicity vs. Versatility

Class N autoclaves are simple, reliable, and generally less expensive. However, their use is strictly limited to unwrapped, non-porous, solid items.

Class B autoclaves offer maximum versatility and can sterilize virtually any medical or laboratory load. This capability comes with increased mechanical complexity due to the vacuum pump.

Cycle Reliability

Because a Class B autoclave actively confirms air removal via its vacuum system, it provides the highest assurance of a successful sterilization cycle, especially for challenging loads. Gravity displacement cycles can fail if items are loaded incorrectly, preventing air from escaping.

Cost and Maintenance

The inclusion of a vacuum pump and more complex control systems makes Class B autoclaves more expensive to purchase and maintain than their Class N counterparts. Class S models fall somewhere in between, depending on their specific mechanisms.

Making the Right Choice for Your Application

Your choice should be dictated entirely by the types of materials you need to sterilize now and in the future.

- If your primary focus is basic lab research: A Class N autoclave is often sufficient for sterilizing media, glassware, and other unwrapped solid instruments.

- If your primary focus is a medical, dental, or veterinary clinic: A Class B autoclave is essential to safely sterilize wrapped instrument kits, textiles, and hollow items.

- If your primary focus is a specific industrial application: A Class S autoclave might be a cost-effective solution if it is specifically validated for your particular load type.

Ultimately, understanding how an autoclave removes air is the key to selecting the right tool for ensuring total sterility.

Summary Table:

| Autoclave Class | Air Removal Method | Best For Load Types | Key Limitation |

|---|---|---|---|

| Class N | Gravity Displacement | Unwrapped, solid items (e.g., glassware) | Cannot sterilize wrapped, hollow, or porous items |

| Class S | Active (e.g., steam pulses) | Specific loads as per manufacturer | Limited versatility; suitability must be validated |

| Class B | Pre-vacuum Cycle | Wrapped kits, hollow instruments, porous textiles | Higher initial cost and maintenance complexity |

Ensure Complete Sterilization in Your Laboratory

Choosing the correct autoclave is critical for the safety and efficiency of your operations. KINTEK specializes in providing the right laboratory equipment for your specific sterilization needs.

We help you:

- Select the ideal autoclave (Class N, S, or B) based on your load types—from simple glassware to complex surgical kits.

- Ensure compliance and reliability with equipment validated for your applications.

- Maximize your investment with expert guidance and support.

Don't compromise on sterility. Let our experts guide you to the perfect solution for your lab's requirements.

Contact KINTEL today for a personalized consultation!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- What are the key parameters for ensuring safe autoclave decontamination? Master Bio-Hazardous Waste Safety

- Why must a Teflon-lined high-pressure autoclave be used for TiO2 bamboo deposition? Ensure Purity and Safety.

- What type of instruments Cannot be autoclaved? Protect Your Equipment from Heat and Moisture Damage

- Which is better dry-heat or steam autoclave? Choose the Right Sterilization Method

- What lab supplies should be autoclaved? A Guide to Safe Sterilization and Decontamination

- What kind of materials are sterilized in the autoclave? A Guide to Steam-Safe Lab Equipment

- How do you sterilize medical equipment in an autoclave? A Guide to a Fail-Safe Process