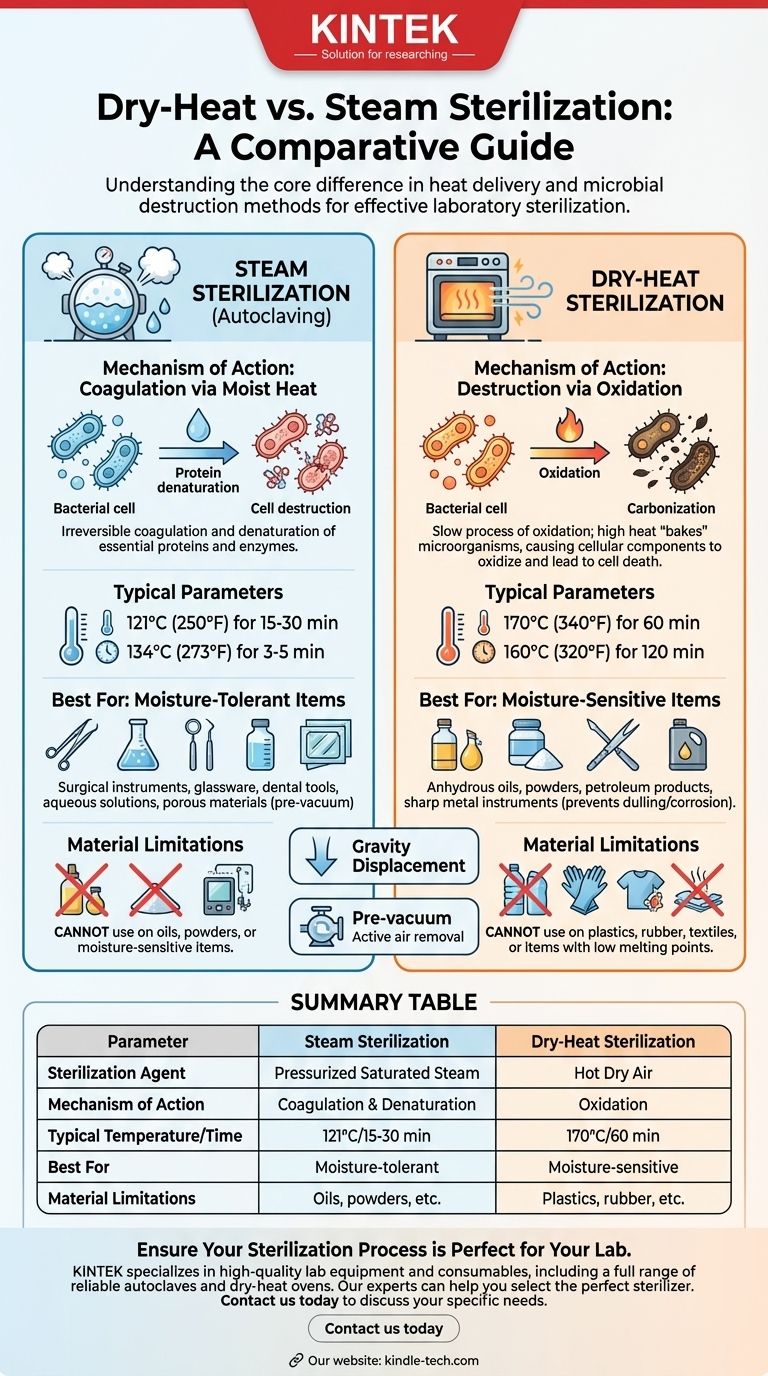

At a fundamental level, the difference between dry-heat and steam sterilization lies in the method of heat delivery and the mechanism of microbial destruction. Steam sterilization, also known as autoclaving, uses pressurized, high-temperature steam to kill microorganisms. In contrast, dry-heat sterilization uses hot, dry air. This distinction leads to significant differences in required temperature, cycle time, and the types of materials that can be safely processed.

The core choice between these methods is a trade-off between speed and material compatibility. Steam sterilization is significantly faster and more efficient due to moisture's ability to transfer heat, but it cannot be used for moisture-sensitive items like oils or powders, where dry heat is the necessary alternative.

How Each Method Achieves Sterility

To select the right process, you must first understand the distinct mechanism by which each method destroys microbial life. They are not interchangeable.

Steam Sterilization: Coagulation via Moist Heat

Steam sterilization works by exposing items to saturated steam under high pressure. This moist heat is exceptionally effective at transferring thermal energy to microorganisms.

The primary kill mechanism is the irreversible coagulation and denaturation of essential proteins and enzymes within the microbial cells. This process is rapid and lethal, effectively disabling and destroying the cells.

Dry-Heat Sterilization: Destruction via Oxidation

Dry-heat sterilization relies on pure thermal energy in the absence of moisture. Because dry air is a less efficient conductor of heat than steam, this process requires much higher temperatures and longer exposure times.

The mechanism of action is a slow, destructive process of oxidation. Essentially, the high heat "bakes" the microorganisms, causing their cellular components to oxidize, which leads to cell death.

Comparing Critical Parameters

The operational differences in time and temperature are the most practical considerations when choosing between these two methods.

The Speed and Efficiency of Steam

Due to the efficiency of moist heat transfer, steam autoclaves operate at lower temperatures for shorter durations. A typical cycle runs at 121°C (250°F) for 15-30 minutes or 134°C (273°F) for 3-5 minutes, not including heat-up and cool-down times.

There are two primary types of steam autoclaves. Gravity displacement autoclaves pump steam into the chamber, displacing the cooler, denser air downwards. Pre-vacuum autoclaves use a vacuum pump to actively remove air before steam is introduced, ensuring faster and deeper penetration into complex or porous items like wrapped surgical kits.

The Slower Pace of Dry Heat

Dry-heat ovens must compensate for the poor thermal transfer of dry air with higher temperatures and significantly longer cycles.

A typical dry-heat cycle runs at 170°C (340°F) for 60 minutes or 160°C (320°F) for 120 minutes. These times do not include the long period it takes for the chamber and its load to reach the target temperature.

Understanding the Trade-offs: Material Compatibility

The most critical decision factor is the material you intend to sterilize. Choosing the wrong method can result in incomplete sterilization or destruction of the item itself.

When to Use Steam Sterilization

Steam is the preferred method for most applications due to its speed and effectiveness. It is ideal for thermostable, moisture-tolerant items.

Common applications include surgical instruments, dental instruments, laboratory glassware, medical waste, and aqueous solutions. It is also the standard for sterilizing porous materials like gowns, dressings, and wrapped instrument kits, provided a pre-vacuum cycle is used.

When Dry Heat is Non-Negotiable

Dry heat is reserved for materials that are either damaged by moisture or impenetrable to it.

This makes it the only choice for sterilizing anhydrous oils, powders, and petroleum products. It is also often preferred for sharp metal instruments, as the absence of moisture prevents the dulling and corrosion that can occur during repeated steam cycles.

Common Pitfalls to Avoid

Never use steam sterilization for oils, powders, or other anhydrous materials, as the steam cannot penetrate them to ensure sterility.

Conversely, never use high-temperature dry heat on materials with low melting points, such as most plastics, rubber items, or textiles, as they will melt, char, or be destroyed.

Making the Right Choice for Your Application

Your choice must be guided by the material being processed and your operational needs for speed and throughput.

- If your primary focus is speed and efficiency for robust, moisture-tolerant materials: Steam sterilization (autoclaving) is the superior and most common choice.

- If you are sterilizing moisture-sensitive items like powders, oils, or sharp instruments prone to rust: Dry-heat sterilization is the only correct and safe method.

- If you are sterilizing porous loads or wrapped surgical kits: A pre-vacuum steam autoclave is required to ensure complete air removal and effective steam penetration.

Understanding these core differences ensures you select the method that guarantees sterility without compromising the integrity of your materials.

Summary Table:

| Parameter | Steam Sterilization | Dry-Heat Sterilization |

|---|---|---|

| Sterilization Agent | Pressurized Saturated Steam | Hot, Dry Air |

| Mechanism of Action | Coagulation & Denaturation of Proteins | Oxidation |

| Typical Temperature/Time | 121°C for 15-30 min | 170°C for 60 min |

| Best For | Moisture-tolerant items (glassware, instruments, waste) | Moisture-sensitive items (oils, powders, sharp instruments) |

| Material Limitations | Cannot be used on oils, powders, or moisture-sensitive items | Cannot be used on plastics, rubber, or other low-melting-point materials |

Ensure Your Sterilization Process is Perfect for Your Lab

Choosing the right sterilization method is critical for the safety of your work and the longevity of your valuable equipment. Whether you need the rapid efficiency of a steam autoclave or the gentle, dry-heat compatibility for sensitive materials, KINTEK has the solution.

KINTEK specializes in high-quality lab equipment and consumables, including a full range of reliable autoclaves and dry-heat ovens. Our experts can help you select the perfect sterilizer to protect your instruments, ensure complete sterility, and optimize your lab's workflow.

Contact us today to discuss your specific needs and find the ideal sterilization equipment for your laboratory.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- Can all materials be sterilized in the autoclave? A Guide to Safe & Effective Sterilization

- How often should an autoclave be serviced? A Risk-Based Guide to Sterilization Compliance

- What is cycle time as related to autoclaving? Master the Full Process for Effective Sterilization

- What function does a PTFE-lined autoclave serve for ZnS nanopowder? Achieve Pure, High-Performance Synthesis

- What are the 3 phases of the autoclave process? Master Sterilization for Lab Safety

- What is the purpose of an autoclave quizlet? Achieve Absolute Sterility for Safety and Integrity

- How does a gravity displacement autoclave function differently than a prevacuum sterilizer? Compare Sterilization Methods

- How does autoclave destroy bacteria? Harness the Power of Pressurized Steam for Sterility