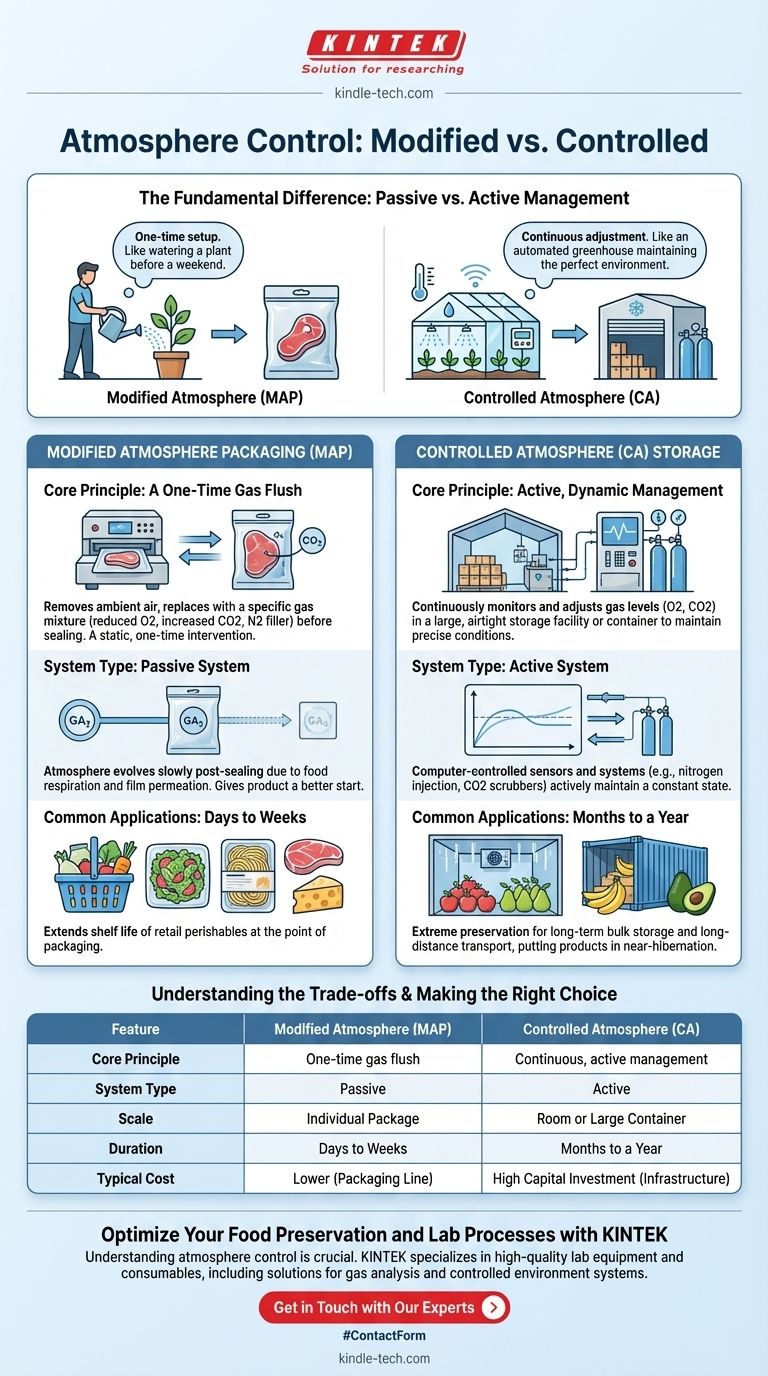

At a fundamental level, the difference between modified atmosphere and controlled atmosphere is a matter of passive versus active management. Modified Atmosphere Packaging (MAP) involves altering the atmosphere inside a package one time before it is sealed. In contrast, Controlled Atmosphere (CA) is a dynamic process that continuously monitors and actively manages the gas composition within a large storage facility or container.

Think of it this way: Modified Atmosphere is like giving a plant a good watering before you leave for a weekend—it's a one-time setup. Controlled Atmosphere is like setting up a fully automated greenhouse that constantly adjusts water, light, and humidity to maintain the perfect environment indefinitely.

What is Modified Atmosphere Packaging (MAP)?

Modified Atmosphere Packaging is a technique used to extend the shelf life of perishable foods at the point of packaging. It is a static, one-time intervention.

The Core Principle: A One-Time Gas Flush

The process involves removing the ambient air from a food package and replacing it with a specific mixture of gases. Once the package is sealed, the process is complete.

The Gas Mixture

This new atmosphere is tailored to the specific product. It typically involves reducing oxygen (O2) to slow spoilage and the growth of aerobic organisms, while increasing carbon dioxide (CO2) to inhibit microbial growth and nitrogen (N2) as an inert filler gas.

A Passive System

After sealing, the atmosphere inside the package will slowly change. This is due to the food's natural respiration process and the slow permeation of gases through the packaging film. The initial modification simply gives the product a better starting point.

Common Applications

You see MAP every day in the grocery store. It is ideal for products like packaged salads, fresh pasta, raw meat, and cheese, where shelf life needs to be extended by days or weeks.

What is Controlled Atmosphere (CA) Storage?

Controlled Atmosphere is a far more complex and active preservation method used for long-term, bulk storage. It is not about the individual package, but the entire storage environment.

The Core Principle: Active, Dynamic Management

CA involves placing products in a large, airtight room or container where the atmosphere is continuously monitored by sensors. A computer-controlled system actively adjusts the gas levels to maintain a precise and constant state.

How It Works

Sensors measure levels of O2, CO2, and other gases in real time. If the oxygen level rises due to a small leak, the system might inject nitrogen. If carbon dioxide from respiring fruit gets too high, a "scrubber" will activate to remove it.

The Goal: Extreme Preservation

The goal of CA is to put the product into a state of near-hibernation. By keeping gas levels at their absolute optimal point, CA can dramatically slow down ripening, aging, and decay for months, or in some cases, over a year.

Common Applications

CA is used for the long-term bulk storage of apples and pears, allowing them to be sold year-round. It is also used in specialized shipping containers for the long-distance transport of produce like bananas and avocados.

Understanding the Trade-offs

Choosing between these methods comes down to balancing control, scale, and cost. The right choice depends entirely on the logistical goal.

Control: Passive vs. Active

MAP is passive. The atmosphere is set once and then left to evolve. CA is active. The atmosphere is constantly managed to remain at a specific setpoint.

Scale: Package vs. Room

MAP applies to the individual package. It is a packaging-line technology. CA applies to the entire room or container. It is an infrastructure technology.

Duration and Cost

MAP is a relatively low-cost addition to a packaging line that can extend shelf life by days or weeks. CA requires a massive capital investment in airtight rooms, sensors, and gas management systems to extend shelf life by months or even a year.

Making the Right Choice for Your Goal

Your objective determines the correct technology.

- If your primary focus is retail packaging for consumers: MAP is the industry standard for extending the freshness and visual appeal of products on the shelf.

- If your primary focus is long-term bulk storage of produce: CA is the essential technology for preserving harvests and managing supply chains across seasons.

- If your primary focus is long-distance international shipping: Specialized CA containers are necessary to ensure perishable goods arrive at their destination in optimal condition.

Ultimately, understanding the distinction between a one-time modification and continuous control is the key to mastering food preservation at any scale.

Summary Table:

| Feature | Modified Atmosphere (MAP) | Controlled Atmosphere (CA) |

|---|---|---|

| Core Principle | One-time gas flush | Continuous, active management |

| System Type | Passive | Active |

| Scale | Individual Package | Room or Large Container |

| Duration | Days to Weeks | Months to a Year |

| Typical Cost | Lower | High Capital Investment |

| Common Applications | Packaged salads, fresh meat, cheese | Long-term storage of apples, pears; international shipping |

Optimize Your Food Preservation and Lab Processes with KINTEK

Understanding the nuances of atmosphere control is crucial for product quality and shelf life. Whether your operations involve food packaging, long-term storage, or precise laboratory environments, having the right equipment is key to success.

KINTEK specializes in high-quality lab equipment and consumables, including solutions for gas analysis and controlled environment systems. We help laboratories and production facilities achieve precise, reliable, and efficient results.

Contact us today to discuss how our expertise can enhance your preservation strategies, improve your lab's efficiency, and ensure the integrity of your products.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is meant by inert atmosphere? A Guide to Preventing Oxidation & Ensuring Safety

- What is an example of an inert atmosphere? Discover the Best Gas for Your Process

- How do you make an inert atmosphere? Master Safe, Pure Processes with Inerting

- How does an atmosphere furnace facilitate the post-treatment of nickel-plated carbon fibers? Ensure Peak Bonding

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes