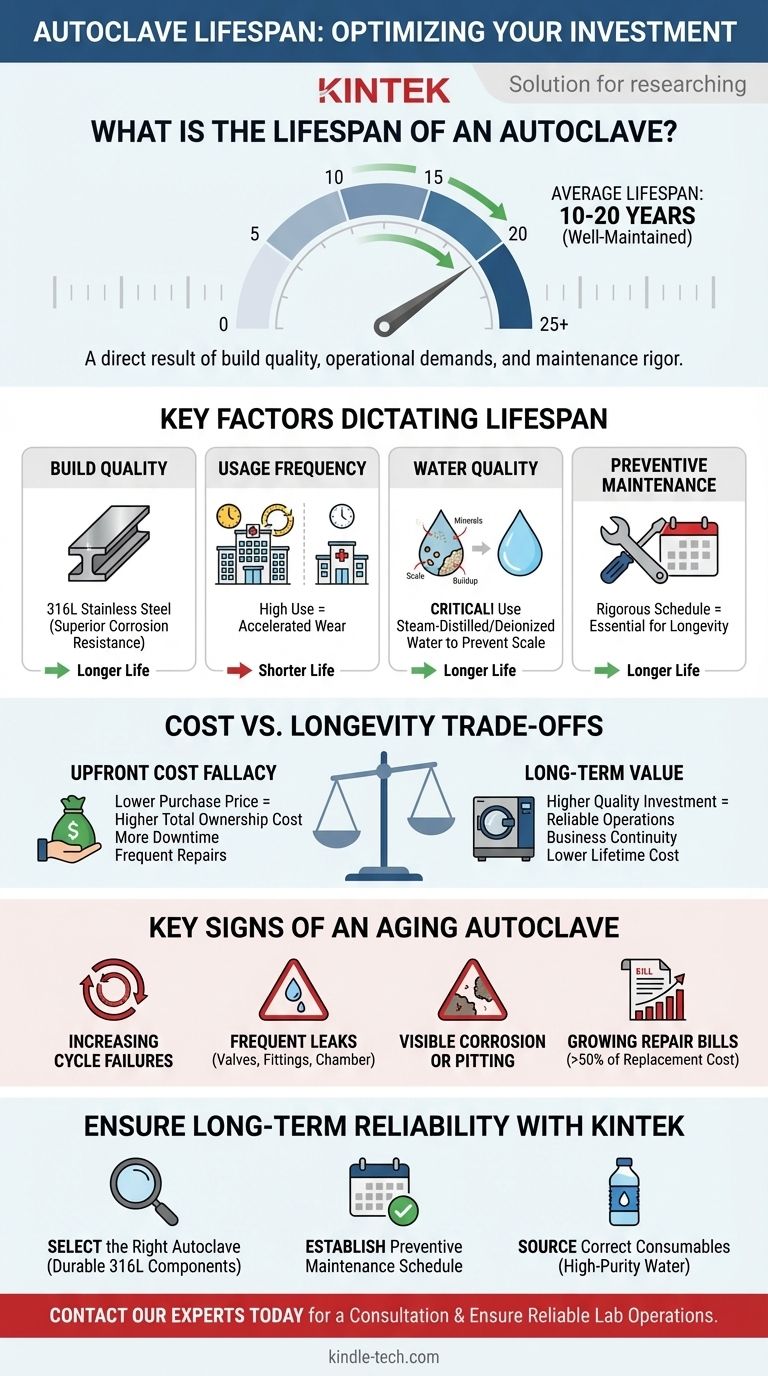

On average, a well-maintained autoclave has a lifespan of 10 to 20 years. This range is heavily influenced by the machine's build quality, how frequently it is used, and, most importantly, the consistency of its preventive maintenance schedule. While some high-end units can exceed 20 years, cheaper or poorly maintained models may fail in less than a decade.

The lifespan of an autoclave is not a fixed expiration date. It is a direct result of its initial manufacturing quality, the operational demands placed upon it, and the rigor of its maintenance and water quality management.

What Determines an Autoclave's Lifespan?

Several key factors work together to dictate how long your autoclave will function reliably. Understanding them is crucial for maximizing your investment.

The Impact of Build Quality

The initial quality of the autoclave is the foundation of its longevity. Premium models use higher-grade 316L stainless steel for the chamber and piping, which offers superior resistance to corrosion compared to the more common 304 stainless steel found in entry-level units.

Usage Frequency and Load Type

An autoclave in a busy hospital running 15-20 cycles per day will experience significantly more wear than one in a small dental office running 3-4 cycles. The constant heating and cooling cycles stress all components, from gaskets and valves to the chamber itself.

Furthermore, the type of materials being sterilized matters. Saline solutions or other chlorides are highly corrosive and can dramatically shorten the life of the chamber if not cleaned properly.

The Critical Role of Water Quality

This is arguably the single most important factor you can control. Using tap water or water with high mineral content is a primary cause of premature autoclave failure.

These impurities create scale buildup on heating elements, sensors, and in the chamber. This scale acts as an insulator, forcing the heating elements to work harder and eventually burn out. It can also clog valves and pipes, leading to pressure faults and failed cycles. Always use steam-distilled or deionized water as specified by the manufacturer.

Understanding the Trade-offs: Cost vs. Longevity

When evaluating an autoclave, it's tempting to focus on the upfront purchase price. However, this often presents a misleading picture of the true cost.

The Upfront Cost Fallacy

A less expensive autoclave may save money initially but often leads to a higher total cost of ownership. These units may use lower-quality components that require more frequent replacement, leading to increased service calls and repair bills.

The Hidden Cost of Downtime

An unreliable autoclave is more than an inconvenience; it can bring your operations to a halt. For medical clinics, labs, and tattoo parlors, downtime means lost revenue and an inability to serve clients. A more robust, reliable unit provides critical business continuity.

The "Repair vs. Replace" Calculation

As an autoclave ages, you will inevitably face the decision to repair a major component or replace the entire unit. A common rule of thumb is to seriously consider replacement if a single repair estimate exceeds 50% of the cost of a new, comparable autoclave.

Key Signs of an Aging Autoclave

Be watchful for these indicators that your autoclave may be nearing the end of its operational life.

Increasing Cycle Failures

If you begin to see a pattern of aborted cycles due to pressure, temperature, or water-level errors, it signals that core components are beginning to fail.

Frequent Leaks

While door gaskets are a consumable part that requires regular replacement, persistent leaks from valves, fittings, or the chamber itself are a serious concern. This indicates failing seals or potential cracks.

Visible Corrosion or Pitting

Routinely inspect the inside of the chamber. Any signs of rust, corrosion, or pitting (small cavities in the metal) are a major red flag. A compromised chamber is a safety hazard and is often prohibitively expensive to repair.

Growing Repair Bills

When service calls become more and more frequent, it's time to start planning for a replacement. Track your annual maintenance and repair costs; when they start escalating, the unit is no longer economical to operate.

Making the Right Choice for Your Goal

Your strategy for managing your autoclave should align with your operational and financial priorities.

- If your primary focus is minimizing upfront cost: Be prepared for a shorter lifespan and budget for more frequent maintenance and potential downtime.

- If your primary focus is long-term reliability: Invest in a unit with high-quality stainless steel components and strictly adhere to the manufacturer's maintenance and water quality guidelines.

- If your primary focus is managing an existing unit: Implement a rigorous preventive maintenance schedule and use only high-purity water to maximize its remaining lifespan.

By viewing your autoclave as a long-term asset defined by its maintenance, you ensure operational reliability and maximize your return on investment.

Summary Table:

| Factor | Impact on Lifespan | Key Consideration |

|---|---|---|

| Build Quality | High | Premium models use 316L stainless steel for superior corrosion resistance. |

| Usage Frequency | High | More cycles per day accelerate wear on components like gaskets and valves. |

| Water Quality | Critical | Impurities cause scale buildup, leading to component failure; use distilled/deionized water. |

| Preventive Maintenance | Essential | A rigorous schedule is the single most important factor for longevity. |

Ensure Your Autoclave's Long-Term Reliability with KINTEK

Maximizing your autoclave's lifespan is crucial for operational continuity and cost-efficiency. At KINTEK, we specialize in providing high-quality laboratory equipment and consumables, along with the expert support needed to protect your investment.

We help you:

- Select the right autoclave with durable components like 316L stainless steel chambers.

- Establish a preventive maintenance schedule to prevent costly downtime and repairs.

- Source the correct consumables, including high-purity water, to prevent scale and corrosion.

Don't let autoclave failure disrupt your workflow. Contact our experts today for a consultation and ensure your lab operates reliably for years to come.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the function of a high-pressure autoclave in MCM-41 synthesis? Architecting Ordered Mesoporous Silica

- How do you sterilise without an autoclave? Effective methods for heat-sensitive materials

- What are the guidelines when sterilizing items with a steam autoclave? Master the 3 Pillars for Guaranteed Sterility

- What is the temperature of autoclave 132? A Guide to High-Speed Sterilization Cycles

- Why is autoclaving so vital? The Definitive Guide to Steam Sterilization

- What are the safety concerns when autoclaving? A Guide to Preventing Burns, Explosions, and Biohazards

- What is the primary function of a laboratory sterilization autoclave? Master the Physics of Wet Heat Sterilization

- How often should autoclave maintenance be performed? A Guide to Reliable Sterilization