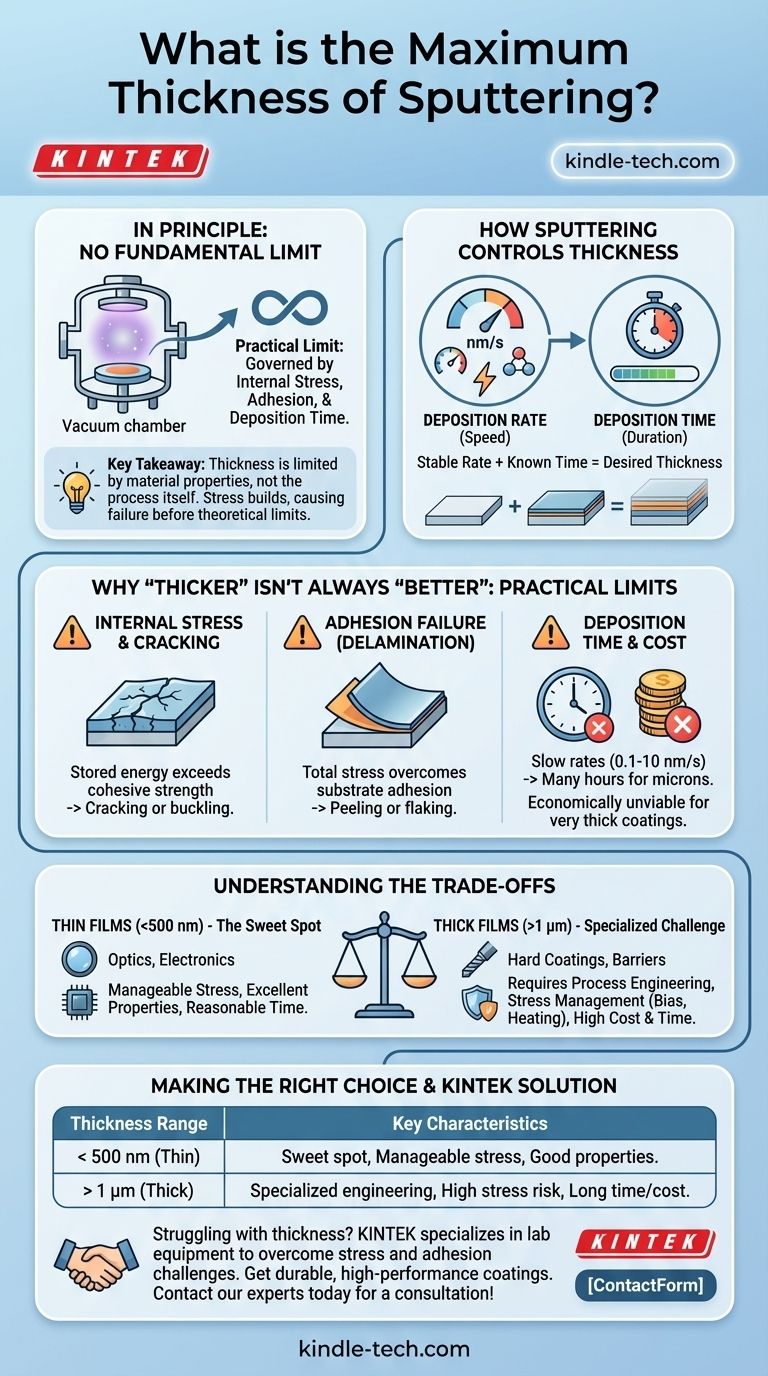

In principle, there is no fundamental upper limit to the thickness of a film you can create with sputtering. However, the practical maximum thickness is governed by internal film stress, adhesion, and deposition time, typically ranging from a few hundred nanometers to several microns for specialized applications.

The key takeaway is that sputtering thickness is not limited by the process itself, but by the material properties of the film being deposited. As thickness increases, internal stress builds, which can cause the film to crack, peel, or delaminate long before a theoretical limit is reached.

How Sputtering Controls Film Thickness

Sputtering is fundamentally a time-based process. You achieve a desired thickness by controlling how long you run the deposition at a known, stable rate.

The Role of Deposition Rate

The deposition rate is the speed at which the material accumulates on your substrate, often measured in angstroms or nanometers per second. This rate is determined by factors like the sputtering power, gas pressure, and the specific material being sputtered.

The Importance of Deposition Time

Once a stable deposition rate is established, film thickness becomes a direct function of time. To create a 50 nm film, you simply run the process for the required duration at a known rate. To create a thicker film, you run it for longer.

Why "Thicker" Isn't Always "Better": Practical Limitations

While you can theoretically run the process indefinitely, you will encounter practical failures long before you deposit a truly "thick" coating (e.g., millimeters). The most significant barrier is internal stress.

Internal Stress and Film Cracking

Nearly all sputtered films have some level of internal stress, which can be either compressive (pushing against itself) or tensile (pulling itself apart). This stress accumulates as the film gets thicker.

At a critical thickness, this stored energy becomes too great. The stress will exceed the film's own cohesive strength, causing it to crack or buckle to relieve the energy.

Adhesion Failure (Delamination)

Similarly, the total stress in the film can overcome its adhesion to the substrate. The thicker the film, the greater the total force pulling it away from the surface.

This results in delamination, where the film peels or flakes off entirely. This is one of the most common failure modes for thick sputtered films.

Deposition Time and Cost

Sputtering deposition rates are often quite slow, typically in the range of 0.1 to 10 nanometers per second.

Depositing a film that is several microns (thousands of nanometers) thick can take many hours. This makes the process extremely slow and economically unviable for applications where very thick coatings are needed quickly.

Understanding the Trade-offs

The "ideal" thickness is a balance between the desired physical property (like wear resistance) and the inherent limitations of stress and time.

Thin Films (< 500 nm): The Sweet Spot

This range, which includes the often-recommended 200 nm mark, is the sweet spot for many applications in optics and electronics.

In this regime, total stress is typically manageable, film properties are excellent, and deposition times are reasonable. The film is thick enough to perform its function without being so thick that it self-destructs.

Thick Films (> 1 µm): The Specialized Challenge

Achieving well-adhered, low-stress films thicker than one micron is possible but requires significant process engineering.

This often involves carefully tuning gas pressure, using substrate biasing, or incorporating periodic heat treatments to manage stress. These films are reserved for demanding applications like hard coatings for tools or thick corrosion barriers.

Making the Right Choice for Your Goal

Your target thickness should be dictated by your end goal and an understanding of the material's limitations.

- If your primary focus is optical or electronic performance: Target the thinnest film that meets your performance specification, as this will minimize stress and cost.

- If your primary focus is wear resistance or barrier protection: Thicker films are likely necessary, but you must plan for process development to manage stress and ensure strong adhesion.

- If your primary focus is cost and throughput: Recognize that sputtering is not efficient for very thick films (many microns); evaluate if other methods like electroplating or thermal spray are a better fit.

Ultimately, the right thickness is determined not by the limits of the sputtering machine, but by the physical demands of your specific application.

Summary Table:

| Thickness Range | Key Characteristics & Considerations |

|---|---|

| < 500 nm (Thin Films) | - Sweet spot for most applications (optics, electronics) - Manageable stress levels - Excellent film properties - Reasonable deposition times |

| > 1 µm (Thick Films) | - Requires specialized process engineering - High risk of cracking/delamination - Needs stress management techniques (bias, heating) - Long deposition times, higher cost |

Struggling to achieve the right sputtered film thickness for your application?

At KINTEK, we specialize in lab equipment and consumables that help you overcome the challenges of internal stress and adhesion. Our expertise ensures you get durable, high-performance coatings tailored to your specific needs—whether for thin-film electronics or thick protective barriers.

Let's optimize your deposition process together. Contact our experts today for a consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition