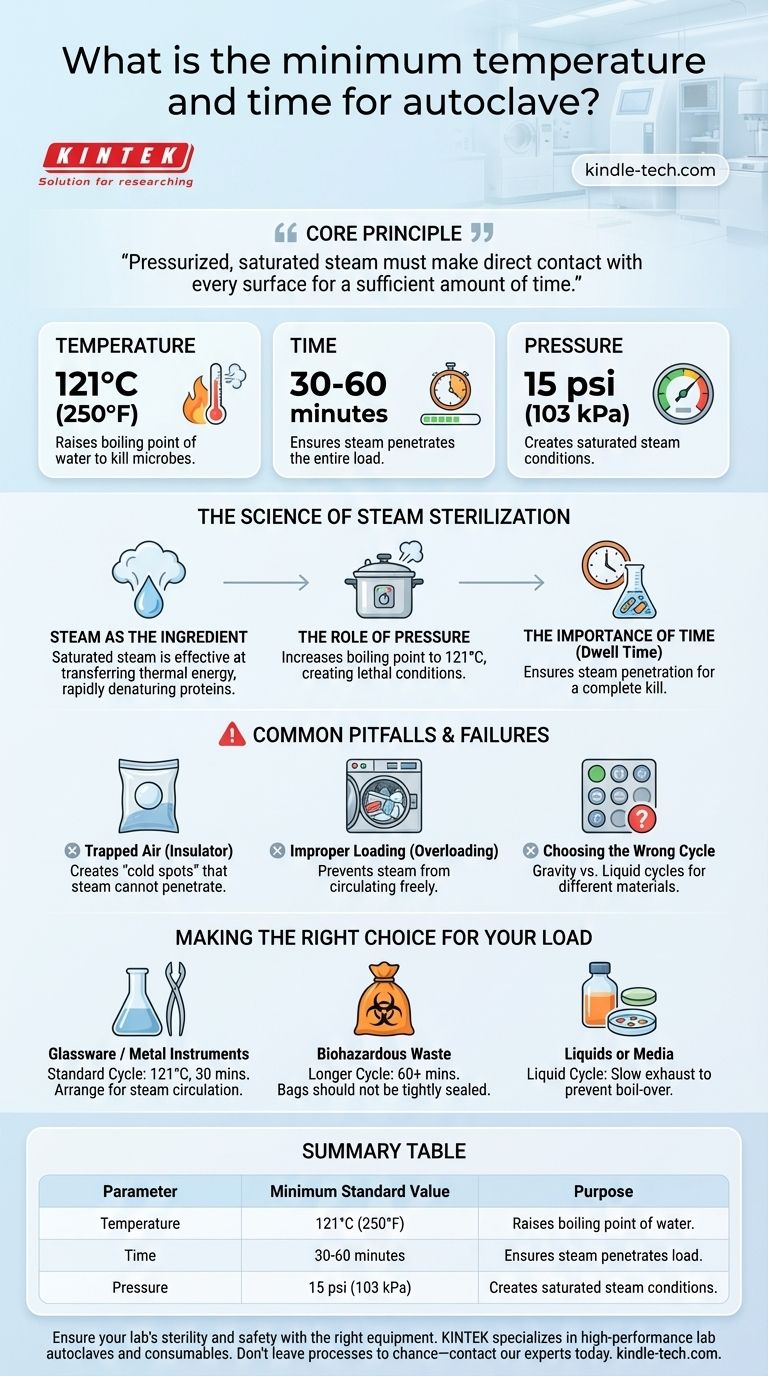

The standard minimum temperature for effective steam sterilization in an autoclave is 121°C (250°F), maintained for a duration that typically ranges from 30 to 60 minutes. This process is conducted under a pressure of approximately 15 psi (103 kPa) to ensure the steam remains saturated and can effectively penetrate the load.

The core principle is not just about reaching a specific temperature, but ensuring that pressurized, saturated steam makes direct contact with every surface for a sufficient amount of time. The temperature and time are merely the required conditions; successful sterilization depends entirely on proper loading and the elimination of trapped air.

The Science of Steam Sterilization

At its core, an autoclave is a highly controlled pressure cooker. Understanding how it works is critical to using it effectively and preventing sterilization failures.

Why Steam is the Critical Ingredient

Saturated steam is far more effective at transferring thermal energy than dry air. The moisture in the steam rapidly denatures the essential proteins and enzymes within microorganisms, leading to their destruction.

The Role of Pressure

The high pressure inside an autoclave serves one primary purpose: to increase the boiling point of water. At normal atmospheric pressure, water boils at 100°C (212°F), which is not hot enough to reliably kill all microbial life, especially tough bacterial spores.

By increasing the pressure to 15 psi above atmospheric pressure, the autoclave forces water to boil at 121°C. This higher temperature, combined with the moisture of the steam, creates an environment lethal to all microorganisms.

The Importance of Time

Time is the final variable in the equation. The "dwell time" or "exposure time" refers to how long the load is held at the target temperature of 121°C. This duration ensures the steam has enough time to penetrate the entire load and achieve a complete kill. A range of 30-60 minutes is standard, with the exact time depending on the load's size and density.

Common Pitfalls That Lead to Sterilization Failure

Achieving the correct temperature, pressure, and time on the autoclave's display does not guarantee sterility. The most common failures are caused by procedural errors.

The Problem of Trapped Air

Air is an excellent insulator and the primary enemy of steam sterilization. If air is trapped within a package or a piece of equipment, it creates a "cold spot" that steam cannot penetrate, leaving that area unsterilized. This is why proper loading and, in some cases, pre-vacuum cycles are essential.

Improper Loading

Overloading the autoclave or packing items too densely prevents steam from circulating freely. All items must be positioned to allow steam to contact every surface. For example, bags should be placed on their side, and containers should never be sealed airtight.

Choosing the Wrong Cycle

Modern autoclaves have different cycles for different materials. A "gravity" cycle is standard for many items, while a "liquid" cycle uses a slower exhaust to prevent liquids from boiling over. Using the wrong cycle can result in incomplete sterilization or damage to the contents.

Making the Right Choice for Your Load

The ideal cycle parameters are determined by what you are sterilizing. Always consult your equipment's manual, but use these principles as a guide.

- If your primary focus is glassware or metal instruments: A standard cycle of 121°C for 30 minutes is typically sufficient, provided items are arranged to allow steam circulation.

- If your primary focus is biohazardous waste: You must ensure complete penetration. Longer cycle times (60 minutes or more) may be necessary, and bags should not be tightly sealed.

- If your primary focus is liquids or media: Use a dedicated liquid cycle with a slow, controlled exhaust to prevent boil-over and ensure the entire volume reaches temperature.

Ultimately, successful sterilization is a process of ensuring that every surface is exposed to the lethal conditions inside the autoclave.

Summary Table:

| Parameter | Minimum Standard Value | Purpose |

|---|---|---|

| Temperature | 121°C (250°F) | Raises boiling point of water to kill microbes |

| Time | 30-60 minutes | Ensures steam penetrates the entire load |

| Pressure | 15 psi (103 kPa) | Creates saturated steam conditions |

Ensure your lab's sterility and safety with the right equipment. Proper autoclaving is critical for reliable results and contamination control. KINTEK specializes in high-performance lab autoclaves and consumables designed for precise temperature and pressure control, ensuring effective sterilization for instruments, media, and waste. Don't leave your processes to chance—contact our experts today to find the perfect autoclave solution for your laboratory's specific needs.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What tests are done on an autoclave? Ensure Sterilization Success with a Complete Testing Protocol

- What to look for when buying an autoclave? A Guide to Selecting the Right Sterilization Technology

- Why is a high-pressure hydrothermal synthesis autoclave necessary for MnO2 nanowires? Precision Catalyst Growth

- How does an autoclave ensure the reliability of experimental results? Achieving a Sterile Baseline for Lab Research

- What is the most effective method for sterilization of laboratory materials? Choose the Right Method for Your Lab

- Do liquids boil in an autoclave? How to Safely Sterilize Media Without Boil-Over

- What does an autoclave do in a microbiology laboratory? Ensuring Sterility and Safety for Your Research

- What is the primary difference between pharmaceutical and waste autoclaves? Purity vs. Sterility Explained