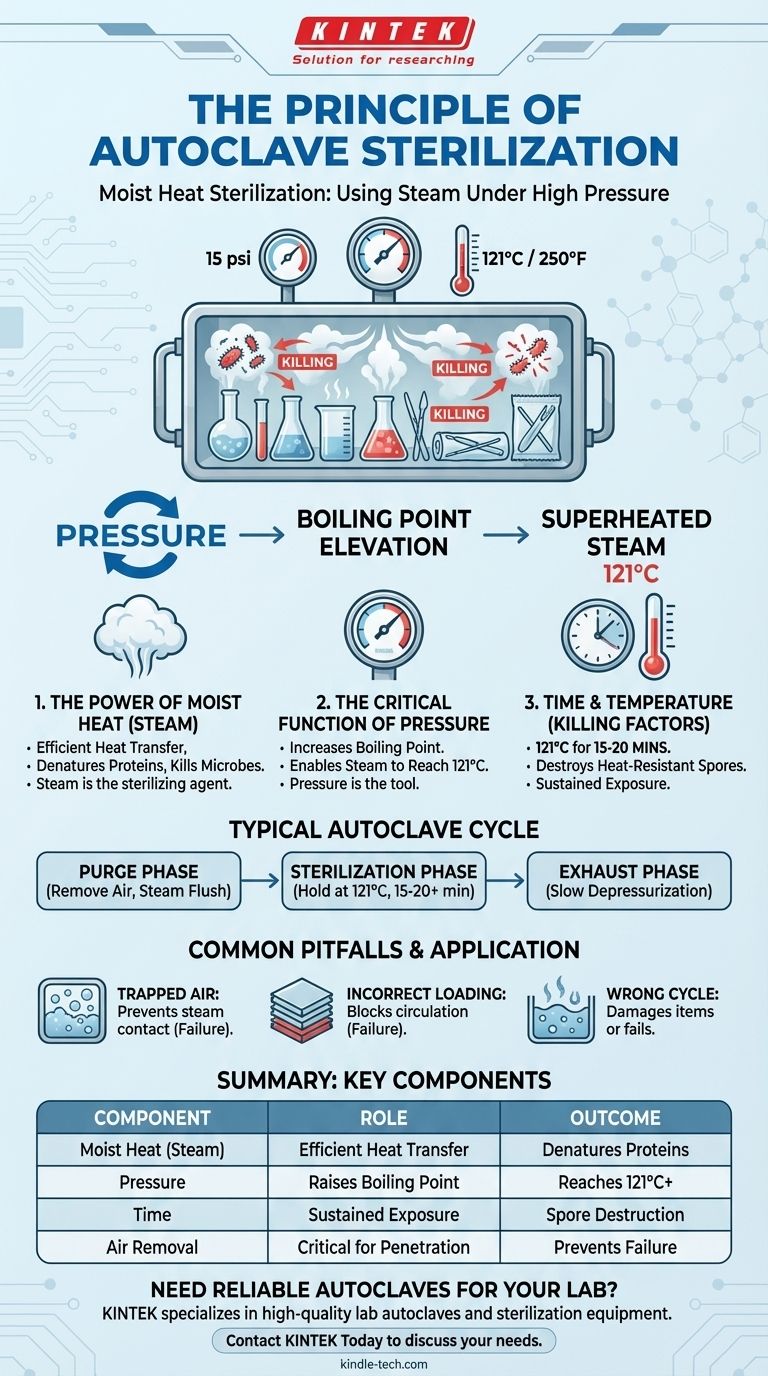

The fundamental principle of an autoclave is moist heat sterilization. It uses steam under high pressure to achieve temperatures far above the normal boiling point of water, which rapidly and effectively kills all forms of microbial life, including resilient spores. The pressure itself is not the sterilizing agent; it is the tool used to create superheated steam.

The core concept to grasp is the relationship between pressure and temperature. By increasing the pressure inside a sealed chamber, an autoclave prevents water from boiling at 100°C (212°F), allowing the steam to reach sterilizing temperatures of 121°C (250°F) or higher.

Deconstructing the Sterilization Process

To truly understand how an autoclave works, you must see how its three key components—moist heat, pressure, and time—work in concert to achieve complete sterilization.

The Power of Moist Heat (Steam)

Moist heat is significantly more effective at sterilization than dry heat. This is because steam is a highly efficient carrier of thermal energy.

When steam condenses on the cooler surface of an object, it rapidly transfers a large amount of heat. This process quickly denatures and coagulates essential proteins and enzymes within microbial cells, leading to their death.

The Critical Function of Pressure

Pressure is the enabling factor in the autoclave process. At standard atmospheric pressure, water boils at 100°C, a temperature that is not sufficient to kill all bacterial spores.

By sealing the chamber and pumping in steam, the autoclave increases the internal pressure. This forces the boiling point of water upward. It is this high-pressure environment that allows the steam to remain gaseous at the required sterilizing temperature of 121°C.

The Killing Factors: Temperature and Time

The actual sterilization is a function of exposing microorganisms to a specific high temperature for a designated amount of time.

A standard and widely validated cycle is maintaining a temperature of 121°C (250°F) for at least 15-20 minutes. This combination of extreme heat and sustained exposure ensures the destruction of even the most heat-resistant bacterial endospores.

How a Typical Autoclave Cycle Works

An autoclave doesn't just instantly apply heat and pressure. It follows a precise, multi-stage process to ensure that steam properly contacts all surfaces of the items inside.

Stage 1: The Purge Phase

Before sterilization can begin, all air must be removed from the chamber. Trapped air creates cool pockets that steam cannot penetrate, leading to sterilization failure.

The autoclave purges this air by flushing the chamber with steam, effectively pushing the cooler, heavier air out through a vent.

Stage 2: The Sterilization Phase

Once all air is removed, the chamber's exhaust valve closes, causing pressure and temperature to rise to the desired setpoint.

The cycle timer begins only after the target temperature is reached. The load is held at this temperature for the entire duration of the programmed time to ensure complete sterilization.

Stage 3: The Exhaust Phase

After the sterilization time is complete, the chamber's exhaust valve opens. Steam is slowly released, allowing the pressure to return to ambient levels.

This depressurization must be done carefully to prevent liquids from boiling over or sealed containers from breaking.

Common Pitfalls and Key Parameters

Achieving successful sterilization requires strict adherence to validated parameters. Misunderstanding the process can easily lead to failed cycles and a false sense of security.

Trapped Air is the Enemy

The most common cause of autoclave failure is improper air removal. If air remains in the chamber or within complex instruments, it prevents steam from making direct contact, leaving those areas unsterilized.

Incorrect Loading

Overloading the autoclave or packing items too densely can also impede steam circulation. This creates barriers that block steam penetration, resulting in incomplete sterilization of the load.

Wrong Cycle Selection

Different materials require different cycles. Sterilizing liquids, for instance, requires a much slower exhaust phase than sterilizing dry goods to prevent the liquids from boiling out of their containers. Using the wrong cycle can damage the items or lead to ineffective sterilization.

Applying This to Your Goal

Understanding the core principles allows you to use and interpret the autoclave process correctly, whether you are in a lab, a clinic, or a manufacturing setting.

- If your primary focus is passing an exam: Remember that pressure's only job is to raise the boiling point of water, allowing moist heat (steam) to reach the 121°C required to kill microbes.

- If your primary focus is operating an autoclave: Always ensure the autoclave is not overloaded and that steam can circulate freely to displace all air from the chamber.

- If your primary focus is validating a process: Recognize that temperature, pressure, and time are all critical, and a failure in one parameter invalidates the entire sterilization cycle.

Ultimately, mastering the principle of the autoclave is about understanding that it is a precisely controlled scientific process, not just a high-temperature wash.

Summary Table:

| Key Component | Role in Sterilization |

|---|---|

| Moist Heat (Steam) | Efficiently transfers heat, denatures microbial proteins |

| Pressure | Raises water's boiling point, enabling steam to reach 121°C+ |

| Time | Sustained exposure at high temperature ensures spore destruction |

| Air Removal | Critical for steam penetration; trapped air causes failure |

Need Reliable Autoclaves for Your Lab?

Understanding autoclave principles is one thing; having equipment that performs reliably is another. KINTEK specializes in high-quality lab autoclaves and sterilization equipment, ensuring your processes meet strict validation standards. Our products are designed for efficient air removal, precise temperature control, and consistent results—critical for labs in research, healthcare, and manufacturing.

Contact KINTEK today to discuss your sterilization needs and ensure your lab operates with confidence and safety.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care

- What is the normal temperature of an autoclave? Achieve Sterile Confidence with Precise Control

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment