Autoclave sterilization is a high-pressure steam treatment used to eliminate all forms of microbial life, including bacteria, viruses, fungi, and heat-resistant spores. The process leverages the physical principle that increasing pressure elevates the boiling point of water, allowing steam to reach temperatures that are far more effective for sterilization than boiling alone.

The core of autoclaving isn't just about high heat; it's about using pressurized steam. This combination allows for rapid heat penetration and uses the moisture in the steam to irreversibly destroy microbial proteins, ensuring complete sterilization.

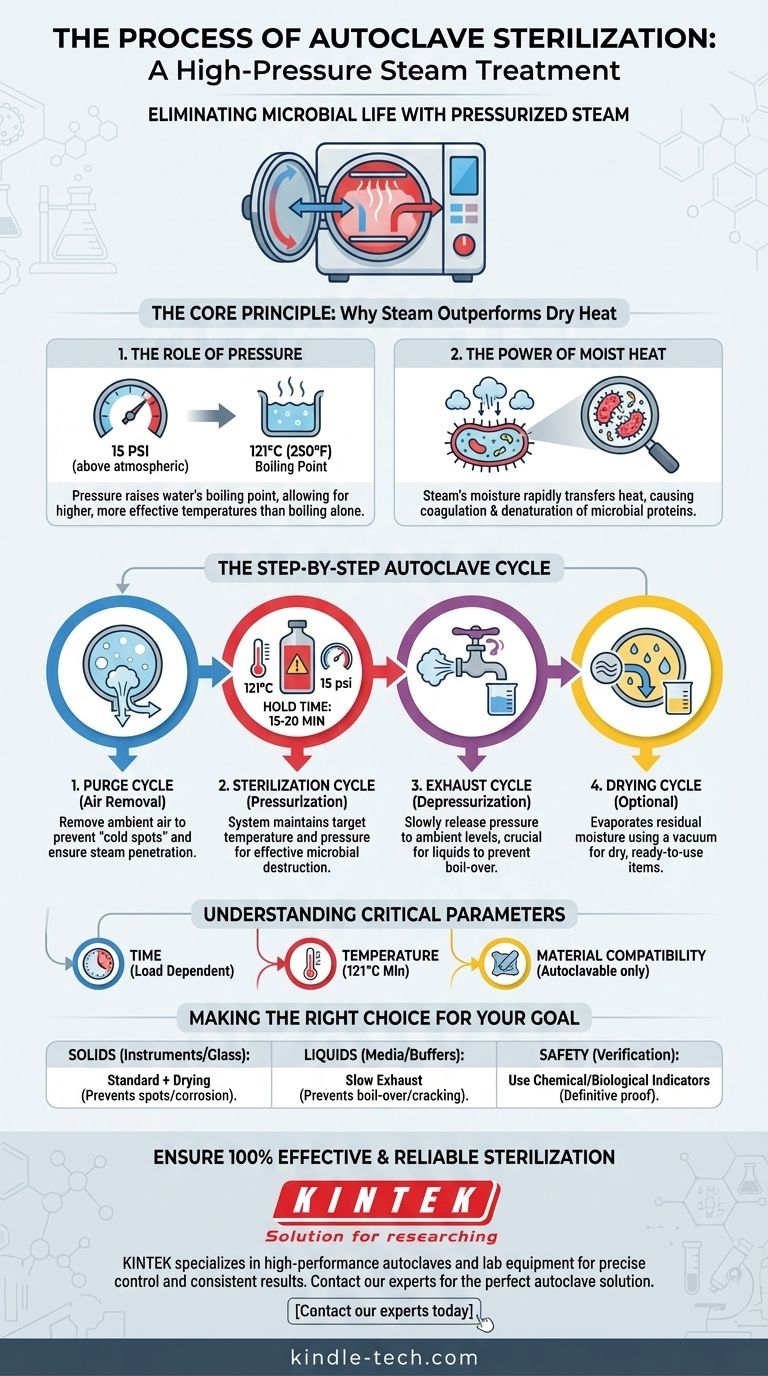

The Core Principle: Why Steam Outperforms Dry Heat

To understand the autoclave process, you must first understand why pressurized steam is the agent of choice. The effectiveness comes down to two key scientific principles.

The Role of Pressure

Under normal atmospheric conditions, water boils at 100°C (212°F). However, inside the sealed chamber of an autoclave, pressure is increased.

According to the gas laws, as pressure on a liquid increases, its boiling point also increases. Autoclaves typically operate at a pressure of 15 pounds per square inch (psi) above atmospheric pressure, which raises the boiling point of water to 121°C (250°F).

The Power of Moist Heat

At this elevated temperature, the steam contains significantly more energy than boiling water or dry hot air. This "moist heat" is the true sterilizing agent.

When this high-temperature steam comes into contact with cooler items, it condenses, rapidly transferring a large amount of thermal energy. Crucially, the moisture causes the coagulation and denaturation of essential proteins and enzymes within the microorganisms, effectively killing them.

The Step-by-Step Autoclave Cycle

While specific models vary, nearly all autoclaves follow a fundamental four-phase cycle to ensure reliable and safe sterilization.

Phase 1: The Purge Cycle (Air Removal)

Once the chamber is sealed, the cycle begins by removing the ambient air. This is a critical step because trapped air can create "cold spots," preventing steam from reaching every surface and leading to sterilization failure.

This is typically achieved by flushing the chamber with steam from the bottom up, forcing the lighter air out through a vent.

Phase 2: The Sterilization Cycle (Pressurization)

With the air removed, the steam vent closes, causing the pressure and temperature inside the chamber to rise rapidly. The system reaches and maintains the target sterilization point, most commonly 121°C at 15 psi.

The duration of this phase, or "hold time," is typically set for 15-20 minutes but can be adjusted based on the size and type of the load.

Phase 3: The Exhaust Cycle (Depressurization)

After the hold time is complete, a valve opens to slowly release the pressurized steam from the chamber. This allows the internal pressure to return to a safe, ambient level.

The rate of exhaust is critical, especially for liquids, as a rapid depressurization would cause them to boil over violently.

Phase 4: The Drying Cycle (Optional)

For items like glassware, instruments, or porous materials, a final drying phase is often programmed. This is achieved by drawing a vacuum on the chamber, which causes any remaining condensed water to boil off at a lower temperature, leaving the items dry and ready for use.

Understanding the Critical Parameters

Successful sterilization isn't automatic. It depends on the precise balance of three interdependent factors and an awareness of material limitations.

Time

The required sterilization time is determined by the load. A large, dense load of surgical instruments requires a longer hold time than a few small glass beakers because it takes more time for the steam to fully penetrate the entire mass.

Temperature

The standard temperature of 121°C is the minimum required to reliably kill heat-resistant bacterial endospores. Lower temperatures will not guarantee complete sterility.

Material Compatibility

Not all materials can withstand the high temperatures and pressures of an autoclave. Heat-sensitive plastics can melt, sharp instruments can be dulled, and certain chemicals or liquids can break down or become hazardous. Always verify that your materials are rated as "autoclavable."

Making the Right Choice for Your Goal

To ensure your process is effective, tailor your cycle parameters to the specific items being sterilized.

- If your primary focus is sterilizing solid instruments (glassware, metal tools): Use a standard cycle with a concluding drying phase to prevent water spots and corrosion.

- If your primary focus is sterilizing liquids (culture media, buffers): Use a cycle with a slow, controlled exhaust phase to prevent the liquid from boiling over and the container from cracking.

- If your primary focus is safety and verification: Always include a chemical or biological indicator in the load to provide definitive proof that sterilization conditions were met.

Ultimately, mastering the autoclave process means understanding it as a controlled scientific procedure, not just a heating cycle.

Summary Table:

| Phase | Key Action | Purpose |

|---|---|---|

| 1. Purge | Remove air from chamber | Eliminate cold spots for complete steam penetration |

| 2. Sterilization | Maintain 121°C at 15 psi | Destroy all microbial life with pressurized steam |

| 3. Exhaust | Slowly release pressure | Safely return chamber to ambient conditions |

| 4. Drying | Evaporate residual moisture | Ensure items are dry and ready for use |

Ensure your lab's sterilization process is 100% effective and reliable. KINTEK specializes in high-performance autoclaves and lab equipment designed for precise temperature and pressure control. Whether you need to sterilize instruments, liquids, or culture media, our solutions deliver consistent, verifiable results.

Contact our experts today to find the perfect autoclave for your laboratory's specific needs and ensure complete peace of mind with every cycle.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- Why must autoclaving be done at 121°C and 15 psi? The Science Behind Guaranteed Sterilization

- Why are the design pressure and temperature ranges of high-pressure autoclaves critical for biomass HTL processes?

- What are the three components of autoclaving? Temperature, Pressure, and Time

- What is the pressure of autoclave at 121 C? The Key to Effective Steam Sterilization

- What other method besides autoclaving achieves sterilization? Compare Dry Heat, Chemical, and Radiation Options

- How is an autoclave checked and maintained? A Guide to Guaranteed Sterilization

- Can all materials be sterilized in the autoclave? A Guide to Safe & Effective Sterilization

- Why is autoclave maintenance important? Ensure Sterilization Efficacy and Safety