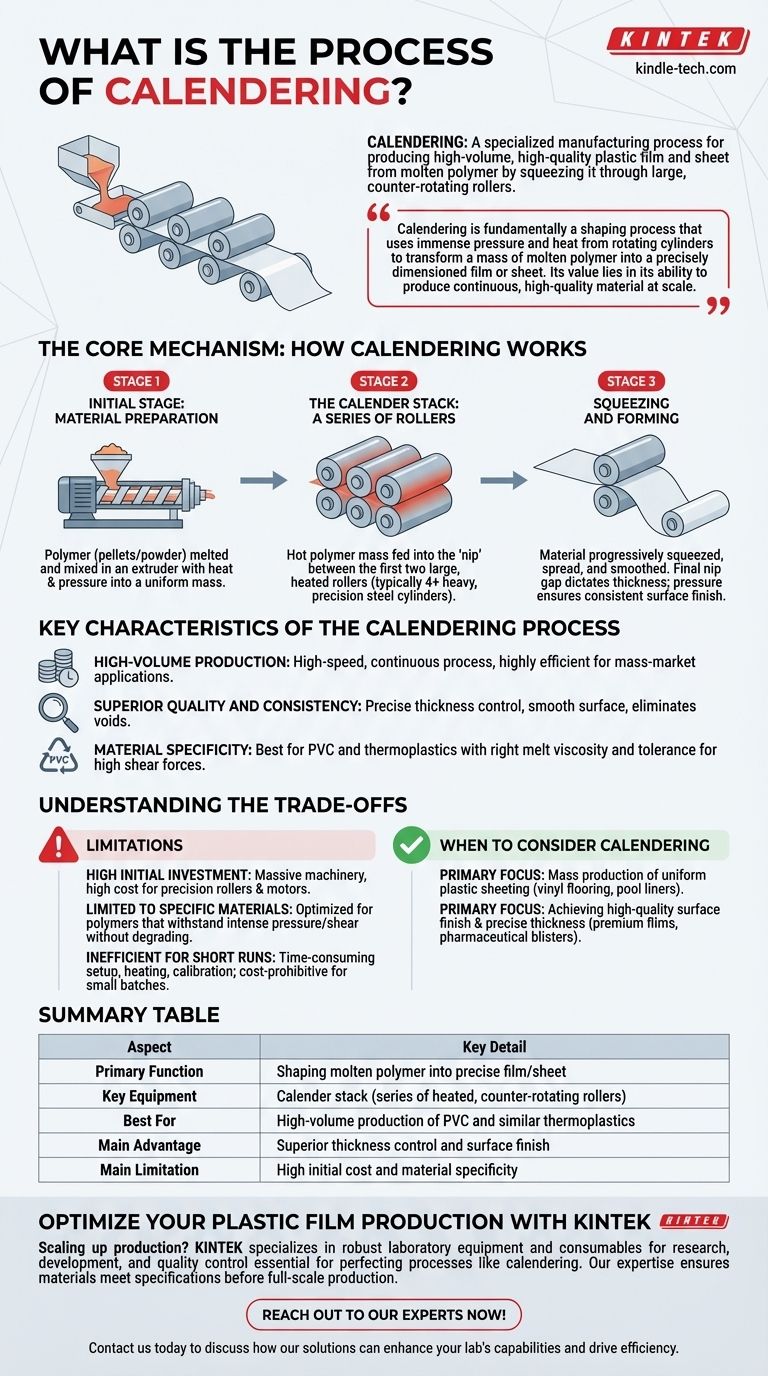

In manufacturing, calendering is a specialized process for producing high-volume, high-quality plastic film and sheet from a molten polymer. The core of the method involves squeezing the heated, pliable material through a series of large, counter-rotating rollers to form it into a continuous layer of precise thickness. It is most commonly associated with PVC and other modified thermoplastics.

Calendering is fundamentally a shaping process that uses immense pressure and heat from rotating cylinders to transform a mass of molten polymer into a precisely dimensioned film or sheet. Its value lies in its ability to produce continuous, high-quality material at scale.

The Core Mechanism: How Calendering Works

The calendering process is a continuous operation that moves from raw material to a finished roll of film or sheet in a seamless flow. It can be broken down into distinct stages centered around the "calender stack" of rollers.

The Initial Stage: Material Preparation

The process begins by preparing the polymer. The plastic, often in pellet or powder form, is melted and mixed in an extruder, where it is subjected to intense heat and pressure to create a uniform, viscous mass ready for forming.

The Calender Stack: A Series of Rollers

This hot polymer mass is then fed directly into the gap, or "nip," between the first two large, heated rollers in a machine known as a calender. These machines typically use four or more of these heavy, precision-engineered steel cylinders.

Squeezing and Forming

As the material passes through the successive gaps between the rollers, it is progressively squeezed, spread, and smoothed. The gap size between the final set of rollers dictates the final thickness of the sheet, while the immense pressure ensures a consistent, high-quality surface finish.

Key Characteristics of the Calendering Process

Understanding the defining features of calendering helps clarify why it is chosen over other film and sheet production methods.

High-Volume Production

Calendering is a high-speed, continuous process. Once running, it can produce vast quantities of film or sheeting with remarkable efficiency, making it ideal for mass-market applications.

Superior Quality and Consistency

The process excels at producing films with very precise thickness control and a smooth, uniform surface. The heavy rollers apply enormous pressure, which eliminates voids and imperfections in the material.

Material Specificity

This method is not suitable for all plastics. It is mainly used for PVC and certain other thermoplastics that have the right melt viscosity and tolerance for the high shear forces involved in the process.

Understanding the Trade-offs

While powerful, calendering is not a universal solution. Its specialized nature comes with specific limitations that are critical to consider.

High Initial Investment

Calendering lines involve massive, heavy machinery that requires significant capital investment. The cost of the precision rollers and the powerful motors needed to drive them makes this an expensive technology to implement.

Limited to Specific Materials

The process is optimized for materials that can withstand the intense pressure and shear forces without degrading. This narrows the range of compatible polymers compared to other methods like extrusion.

Inefficient for Short Runs

The setup, heating, and calibration of a calendering line are time-consuming. This makes the process highly inefficient and cost-prohibitive for small production volumes or custom one-off jobs.

When to Consider Calendering

The decision to use calendering is driven entirely by the specific goals of your production environment.

- If your primary focus is mass production of uniform plastic sheeting: Calendering is an ideal choice due to its high speed and consistent, repeatable output for products like vinyl flooring or pool liners.

- If your primary focus is achieving a high-quality surface finish and precise thickness: The immense pressure of the rollers makes calendering superior for applications like premium decorative films or pharmaceutical blister packs.

- If your primary focus is low-volume production or material versatility: Alternative methods like flat die extrusion would be more cost-effective and flexible for smaller projects or a wider range of plastics.

Ultimately, choosing calendering is a strategic decision for large-scale operations where material consistency and production volume are paramount.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Shaping molten polymer into precise film/sheet |

| Key Equipment | Calender stack (series of heated, counter-rotating rollers) |

| Best For | High-volume production of PVC and similar thermoplastics |

| Main Advantage | Superior thickness control and surface finish |

| Main Limitation | High initial cost and material specificity |

Optimize Your Plastic Film Production with KINTEK

Are you scaling up production of high-quality PVC or thermoplastic sheets? The precision and consistency of the calendering process are critical to your success. At KINTEK, we specialize in providing robust laboratory equipment and consumables that support the research, development, and quality control essential for perfecting manufacturing processes like calendering.

Our expertise helps ensure your materials meet exact thickness and finish specifications before full-scale production. Contact us today to discuss how our solutions can enhance your lab's capabilities and drive efficiency in your manufacturing pipeline.

Visual Guide

Related Products

- Small Lab Rubber Calendering Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What is the principle of calendering? Enhance Fabric Surface with Heat and Pressure

- How does a grinding mill work? A Guide to Crushing, Grinding, and Pulverizing

- What is the process of calendering in plastic processing? A Guide to High-Volume Film & Sheet Production

- What is a calendering machine? Transform Material Surfaces with Precision

- What does calendering do for fabric? Transform Fabric's Look, Feel, and Performance