The primary purpose of an autoclave is to achieve absolute sterilization by using high-pressure steam to kill all forms of microbial life. It operates on the principle of moist heat sterilization, where applying pressure to a sealed chamber increases the boiling point of water well above 100°C (212°F), allowing superheated steam to rapidly penetrate and destroy resilient bacteria, viruses, and spores.

The core principle is simple yet powerful: pressure transforms ordinary steam into a highly effective sterilizing agent. By raising the boiling point of water, an autoclave ensures that heat penetrates materials more deeply and quickly than boiling water or dry heat ever could, guaranteeing the destruction of even the most resistant microorganisms.

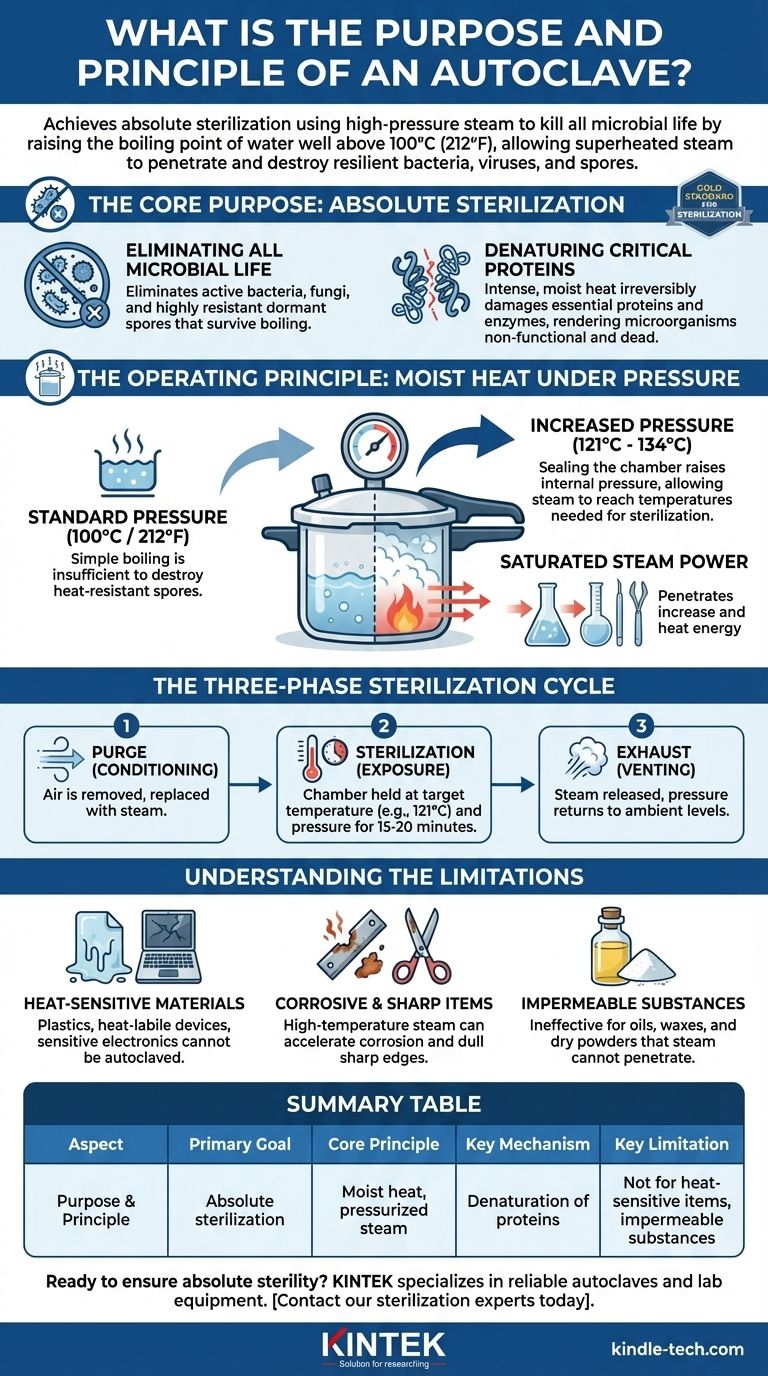

The Core Purpose: Absolute Sterilization

An autoclave is not merely a cleaning device; it is a tool for achieving a complete sterile state. This is a critical distinction in medical, research, and industrial settings where any surviving microbe can compromise safety or experimental integrity.

Eliminating All Microbial Life

The primary function is to completely eliminate or inactivate all forms of life. This includes active bacteria and fungi as well as their highly resistant, dormant forms known as spores, which can survive boiling at normal atmospheric pressure.

Denaturing Critical Proteins

The intense, moist heat works by denaturing the essential proteins and enzymes within microorganisms. This process irreversibly damages their cellular structures and metabolic pathways, rendering them non-functional and dead.

Why It's the Gold Standard

Autoclaving, or steam sterilization, is considered the most reliable and effective method for sterilizing laboratory equipment and decontaminating biohazardous waste. Its ability to destroy resilient spores makes it superior to chemical disinfectants or simple boiling for critical applications.

The Operating Principle: Moist Heat Under Pressure

Understanding how an autoclave works reveals why it is so effective. It leverages a fundamental law of physics to create an environment that is inhospitable to all life.

The Problem with Simple Boiling

At standard atmospheric pressure, water boils at 100°C (212°F). While this temperature kills many microbes, it is not sufficient to reliably destroy heat-resistant bacterial spores. Simply boiling an object does not guarantee sterilization.

How Pressure Changes the Game

An autoclave is essentially a sophisticated pressure cooker. By sealing the chamber and pumping in steam, the internal pressure increases significantly. This increased pressure raises the boiling point of water, allowing the steam to reach temperatures of 121°C to 134°C.

The Power of Saturated Steam

At these higher temperatures, the saturated steam has a tremendous capacity to transfer heat energy. When it makes contact with cooler items in the chamber, it condenses back into water, releasing its thermal energy rapidly and efficiently. This ensures quick and deep heat penetration, even into dense materials or the interior of complex equipment.

The Three-Phase Sterilization Cycle

A typical autoclave cycle consists of three key phases:

- Purge (or Conditioning): Air, which is a poor conductor of heat, is removed from the chamber and replaced with steam.

- Sterilization (or Exposure): The chamber is held at the target temperature and pressure (e.g., 121°C at 15 psi) for a set time, typically 15-20 minutes, to ensure complete killing.

- Exhaust (or Venting): The steam is released, and the pressure returns to ambient levels, allowing the sterilized items to be removed.

Understanding the Limitations

While highly effective, an autoclave is not a universal solution. Understanding its limitations is crucial for preventing equipment damage and ensuring operator safety.

Heat-Sensitive Materials

Materials that can melt, deform, or be destroyed by high temperatures cannot be autoclaved. This includes many plastics, heat-labile medical devices, and sensitive electronic equipment.

Corrosive and Sharp Items

The high-temperature steam can accelerate corrosion on some metals and may dull the sharp edges of instruments like scalpels or scissors over repeated cycles.

Impermeable Substances

The principle of moist heat sterilization relies on steam penetration. Therefore, autoclaving is ineffective for substances that steam cannot penetrate, such as oils, waxes, and dry powders. These require different sterilization methods, like dry heat ovens.

Making the Right Choice for Your Goal

To use an autoclave effectively, match its function to your specific objective.

- If your primary focus is routine sterilization of lab glassware: The standard gravity cycle (121°C for 15-20 minutes) is your reliable workhorse for beakers, flasks, and media preparation.

- If your primary focus is decontaminating biohazardous waste: Use a longer cycle time and ensure proper containment in autoclave-safe bags to guarantee the inactivation of all potential pathogens.

- If your primary focus is sterilizing heat-sensitive liquids or instruments: You must first confirm the item is autoclavable and may need to use a specialized, slower liquid cycle to prevent boil-over or damage.

Ultimately, mastering the autoclave begins with understanding that its power comes from the controlled application of pressurized steam to achieve true sterility.

Summary Table:

| Aspect | Purpose & Principle |

|---|---|

| Primary Goal | Absolute sterilization by eliminating all microbial life (bacteria, viruses, spores). |

| Core Principle | Moist heat sterilization using pressurized steam to raise water's boiling point above 100°C (typically 121°C). |

| Key Mechanism | Denaturation of microbial proteins and enzymes through rapid, deep heat penetration. |

| Key Limitation | Not suitable for heat-sensitive materials, certain plastics, oils, waxes, or dry powders. |

Ready to ensure absolute sterility in your lab?

KINTEK specializes in providing reliable autoclaves and lab equipment tailored to your sterilization and decontamination needs. Whether you're processing glassware, media, or biohazardous waste, our solutions deliver the precise, high-pressure steam performance required for complete safety and compliance.

Contact our sterilization experts today to find the perfect autoclave for your laboratory.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What role does an autoclave play in remediation experiments? Ensure Precision by Eliminating Biological Noise

- How should solid materials in bags be prepared for decontamination? Master Steam Penetration for Safe Sterilization

- What is the necessity of using a steam autoclave for dental alloys? Ensure Pure Bacterial Adhesion Data

- What is the primary purpose of an autoclave in the preparation of media for the biological leaching of uranium?

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing