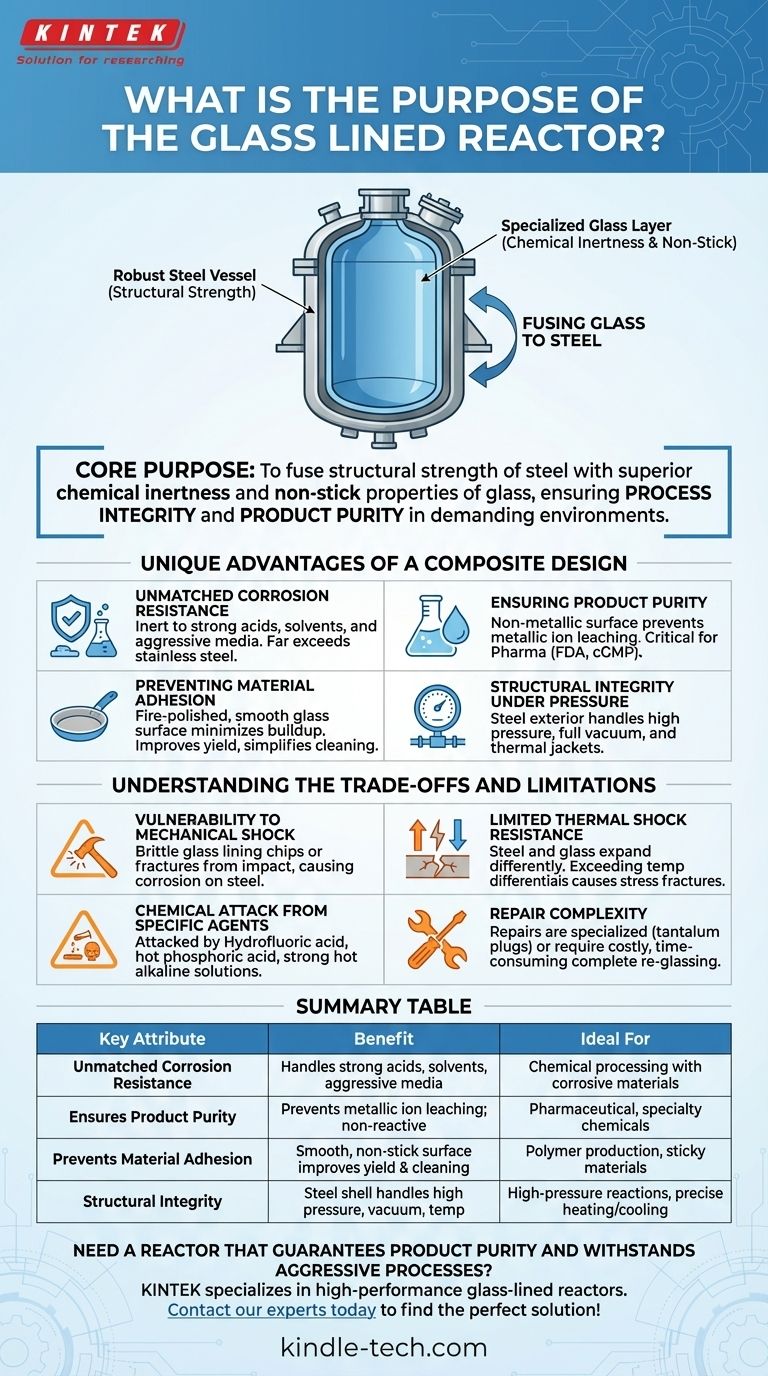

At its core, a glass-lined reactor is a composite vessel designed to handle highly corrosive, sticky, or purity-sensitive chemicals in demanding industrial environments. It accomplishes this by fusing a specialized layer of glass formulation to the interior surface of a robust steel vessel. This creates a unique piece of equipment that provides the structural strength of steel with the superior chemical inertness and non-stick properties of glass.

The fundamental purpose of a glass-lined reactor is not merely to resist corrosion, but to ensure process integrity and product purity. It creates an inert, non-contaminating environment within a vessel strong enough to handle high pressures and temperatures, protecting both the product from contamination and the equipment from aggressive chemicals.

The Unique Advantages of a Composite Design

A glass-lined reactor (GLR) is often chosen when a standard metal alloy reactor, such as stainless steel, is insufficient. The decision hinges on leveraging the unique synergy between its two core materials.

Unmatched Corrosion Resistance

The primary driver for using a GLR is its exceptional resistance to a wide range of chemicals.

The glass lining is inert to most strong acids (like hydrochloric, sulfuric, and nitric acid), solvents, and other aggressive media across a wide temperature range. This far exceeds the capabilities of most stainless steel alloys.

Ensuring Product Purity

In industries like pharmaceuticals and specialty chemicals, even trace amounts of metallic contamination can ruin a batch or cause unwanted side reactions.

The glass surface is non-metallic and non-reactive, preventing metallic ion leaching into the product. This ensures the final product meets stringent purity specifications, which is critical for FDA and cGMP compliance.

Preventing Material Adhesion

Many chemical processes, particularly in polymer production, involve materials that are sticky or prone to building up on vessel walls.

The fire-polished, smooth surface of the glass lining minimizes adhesion. This improves product yield, reduces batch-to-batch contamination, and simplifies cleaning cycles, often making Clean-in-Place (CIP) procedures more effective.

Structural Integrity Under Pressure

While a solid glass vessel would be too fragile for industrial use, the steel exterior provides the necessary mechanical strength.

This allows the reactor to safely handle high-pressure reactions, full vacuum conditions, and the stresses of external jackets used for precise heating and cooling.

Understanding the Trade-offs and Limitations

While powerful, a glass-lined reactor is not a universally superior solution. Its composite nature introduces specific vulnerabilities that require careful operational procedures.

Vulnerability to Mechanical Shock

The glass lining is inherently brittle and is the reactor's most significant weakness.

Dropping tools, metal components, or even the impact from a fast-closing valve can cause the glass to chip or fracture. This damage, known as impact damage, creates a site for immediate corrosive attack on the underlying steel.

Limited Thermal Shock Resistance

The steel shell and the glass lining expand and contract at different rates when heated or cooled.

Exceeding the manufacturer's recommended temperature differentials between the vessel contents and the heating/cooling jacket can cause stress fractures in the glass. This thermal shock is a leading cause of premature failure.

Chemical Attack from Specific Agents

While highly resistant, the glass is not invincible.

It is rapidly attacked by hydrofluoric acid, hot concentrated phosphoric acid, and strong, hot alkaline solutions (high pH). Using a GLR with these chemicals will destroy the lining.

Repair Complexity

Damage to a glass lining is not a simple fix like welding a steel tank.

Repairs often involve specialized technicians who use plugs made of tantalum or other resistant materials. Severe damage may require the entire vessel to be removed from service and sent for a complete re-glassing, which is a costly and time-consuming process.

Making the Right Choice for Your Process

Selecting the right reactor material is a critical decision based on your specific chemical process, operational environment, and budget. A glass-lined reactor excels where purity and corrosion are the primary challenges.

- If your primary focus is product purity and handling aggressive acids: A glass-lined reactor is the industry standard and almost always the superior choice, especially for pharmaceutical or specialty chemical applications.

- If your primary focus is handling high temperatures and abrasive slurries: The risk of thermal shock and mechanical damage is too high; consider a vessel made from a high-performance alloy like Hastelloy or titanium instead.

- If your primary focus is general-purpose processing with moderate corrosives: Stainless steel is often the more cost-effective and robust solution due to its greater tolerance for operational errors and mechanical stress.

Ultimately, a glass-lined reactor is a high-performance tool for processes where chemical inertness and product integrity are non-negotiable.

Summary Table:

| Key Attribute | Benefit | Ideal For |

|---|---|---|

| Unmatched Corrosion Resistance | Handles strong acids, solvents, and aggressive media | Chemical processing with corrosive materials |

| Ensures Product Purity | Prevents metallic ion leaching; non-reactive surface | Pharmaceutical, specialty chemicals (FDA/cGMP) |

| Prevents Material Adhesion | Smooth, non-stick surface improves yield and cleaning | Polymer production, sticky materials |

| Structural Integrity | Steel shell handles high pressure, vacuum, and temperature | High-pressure reactions, precise heating/cooling |

Need a reactor that guarantees product purity and withstands your most aggressive processes? KINTEK specializes in high-performance lab equipment, including glass-lined reactors designed for the toughest chemical environments. Our reactors ensure your processes meet the highest standards of corrosion resistance and contamination control. Contact our experts today to find the perfect solution for your laboratory's unique needs!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research