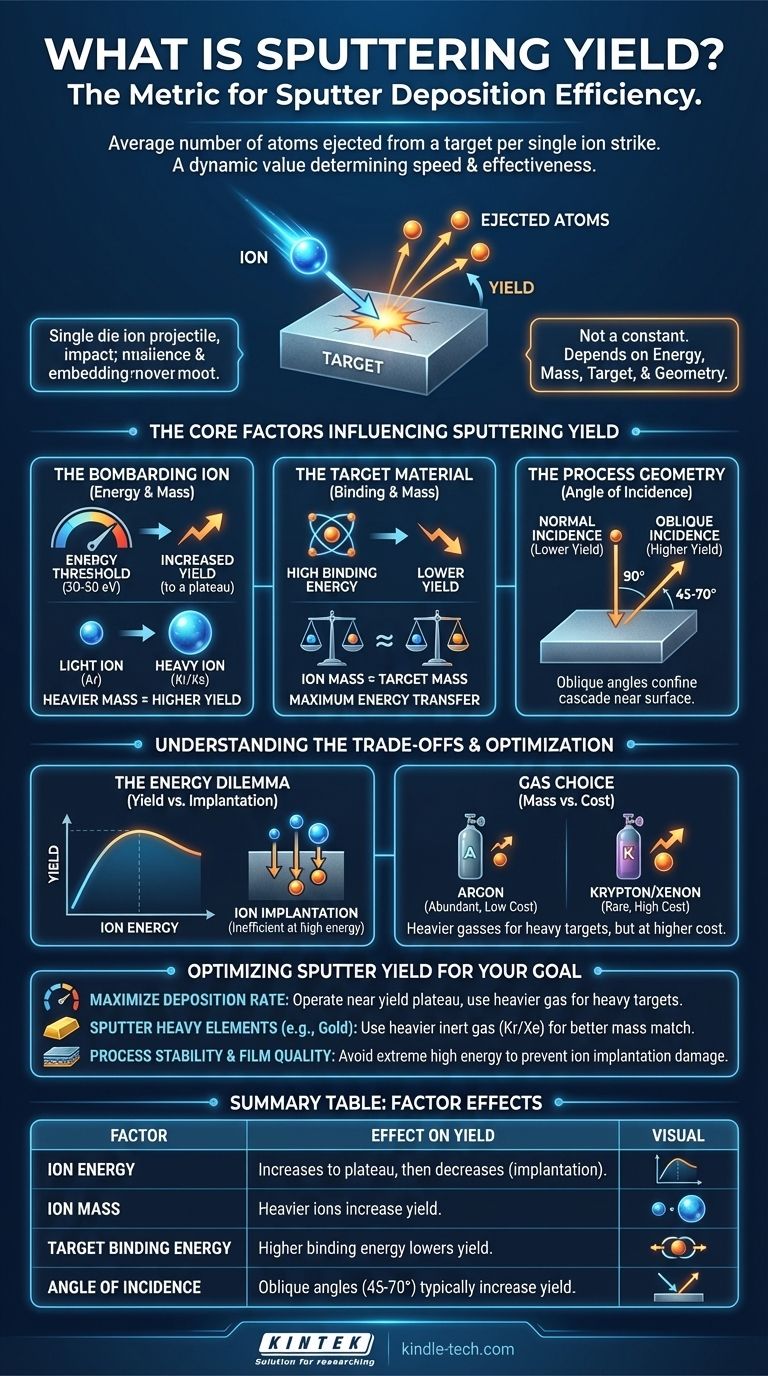

In any sputter deposition process, the sputtering yield is the single most important metric for efficiency. It is defined as the average number of atoms ejected from a target material for each single ion that strikes its surface. This value is not a constant; it is a dynamic outcome that determines the speed and effectiveness of your deposition.

Sputtering yield is not a fixed property of a material, but a variable result of the interaction between three key elements: the energy and mass of the bombarding ion, the physical properties of the target material, and the geometry of the collision.

The Core Factors Influencing Sputtering Yield

To control a sputtering process, you must first understand the variables that dictate its yield. These factors can be grouped into the properties of the ion, the properties of the target, and the conditions of the process itself.

The Bombarding Ion: Energy and Mass

The characteristics of the ion used for bombardment are the primary levers for controlling yield. The most common sputter gas is Argon, an inert gas that is readily ionized.

An ion must possess a minimum amount of kinetic energy to successfully eject a target atom. This energy threshold is typically between 30 and 50 electron volts (eV).

Above this threshold, the sputtering yield generally increases with ion energy. More energy allows for a more forceful collision cascade, ejecting more atoms.

However, at very high energies, the yield begins to plateau. This is because the high-energy ions penetrate deeper into the target, depositing their energy below the surface where it is less effective at ejecting surface atoms.

The mass of the ion is also critical. A heavier ion carries more momentum, and the efficiency of momentum transfer during the collision directly impacts the yield. Yield increases as the mass of the bombarding ion increases.

The Target Material: Binding Energy and Mass

The nature of the material you are trying to sputter is just as important as the ion you use to hit it.

Every material has a specific surface binding energy, which is the energy required to remove an atom from its surface. Materials with a higher surface binding energy are more difficult to sputter and will therefore have a lower sputtering yield.

The mass of the target atoms plays a role in the momentum transfer equation. The maximum transfer of energy occurs when the mass of the incident ion is closely matched to the mass of the target atom.

For crystalline materials, the yield is also dependent on the orientation of the crystal axes relative to the ion beam. Ions traveling down open "channels" in the crystal lattice will penetrate deeper and produce less sputtering than ions striking a more densely packed crystal face.

The Process Geometry: Angle of Incidence

The angle at which the ions strike the target surface has a significant effect.

For ions hitting the target at a normal (90°) angle, the yield is often lower than for ions striking at an oblique angle (e.g., 45-70°). Oblique impacts tend to confine the collision cascade closer to the surface, increasing the probability of atom ejection.

However, at very shallow angles, the ions are more likely to simply reflect off the surface, which causes the sputtering yield to drop off sharply.

Understanding the Trade-offs

Optimizing for sputtering yield is rarely a simple matter of maximizing a single variable. It involves balancing competing factors to achieve the desired outcome.

The Energy Dilemma: Yield vs. Implantation

While higher energy increases yield, there is a point of diminishing returns. Exceeding the optimal energy range can lead to ion implantation, where the bombarding ions become embedded deep within the target rather than sputtering its surface. This is inefficient and can contaminate the target.

The Gas Choice: Mass vs. Cost

The principle of mass matching suggests that to sputter a heavy target material (like gold), one should use a heavy inert gas (like Krypton or Xenon) instead of Argon. This will produce a much higher yield.

The trade-off is cost and availability. Argon is abundant and inexpensive, whereas Krypton and Xenon are significantly more expensive, making them practical only for specific high-value applications.

System Parameters: Direct vs. Indirect Control

Factors like magnetic field strength and plasma gas pressure are system-level controls that indirectly influence the sputter yield.

A stronger magnetic field can confine the plasma closer to the target, increasing ion density and altering ion energy. Likewise, changing the gas pressure affects the mean free path of the ions, which can change the energy and directionality with which they strike the target.

Optimizing Sputter Yield for Your Goal

The "best" sputtering yield is the one that aligns with your specific process objective. Your approach should be tailored to whether your priority is raw deposition speed, material purity, or process control.

- If your primary focus is maximizing deposition rate: Operate at an energy just below the plateau of the yield curve and consider using a heavier sputter gas if the target material is also heavy.

- If your primary focus is sputtering a heavy element target (e.g., Gold, Tungsten): Use a heavier inert gas like Krypton or Xenon to improve the mass match and achieve a higher yield than is possible with Argon.

- If your primary focus is process stability and film quality: Avoid operating at the extreme high-energy end of the curve to prevent ion implantation and potential damage to the growing film from high-energy particles.

Mastering these variables is the key to moving from simply running a sputtering process to truly engineering a desired thin-film outcome.

Summary Table:

| Factor | Effect on Sputtering Yield |

|---|---|

| Ion Energy | Increases with energy up to a plateau, then decreases due to implantation. |

| Ion Mass | Heavier ions (e.g., Xe vs. Ar) increase yield, especially for heavy targets. |

| Target Binding Energy | Higher binding energy lowers the sputtering yield. |

| Angle of Incidence | Oblique angles (e.g., 45-70°) typically increase yield vs. normal (90°) impact. |

Ready to Optimize Your Sputtering Process?

Understanding sputtering yield is the first step to achieving faster deposition rates, higher purity films, and better process control. The experts at KINTEK specialize in providing the right lab equipment and consumables to help you master these variables.

Whether you are working with heavy elements like gold or require stable, high-quality thin films, we have the solutions to meet your laboratory's specific needs.

Contact us today to discuss how we can help you engineer your desired thin-film outcome!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings