In the context of thin-film deposition, sputtering yield is the average number of atoms ejected from a target material for each single energetic ion that strikes its surface. It is a fundamental metric that quantifies the efficiency of the sputtering process. A higher yield means more material is removed from the target for each ion, generally leading to a faster deposition rate.

Sputtering yield is not a fixed property of a material but a dynamic outcome of a collision event. It is fundamentally governed by the efficiency of energy transfer between an incoming ion and the target's surface atoms, which is controlled by ion energy, mass, angle, and the target's own binding energy.

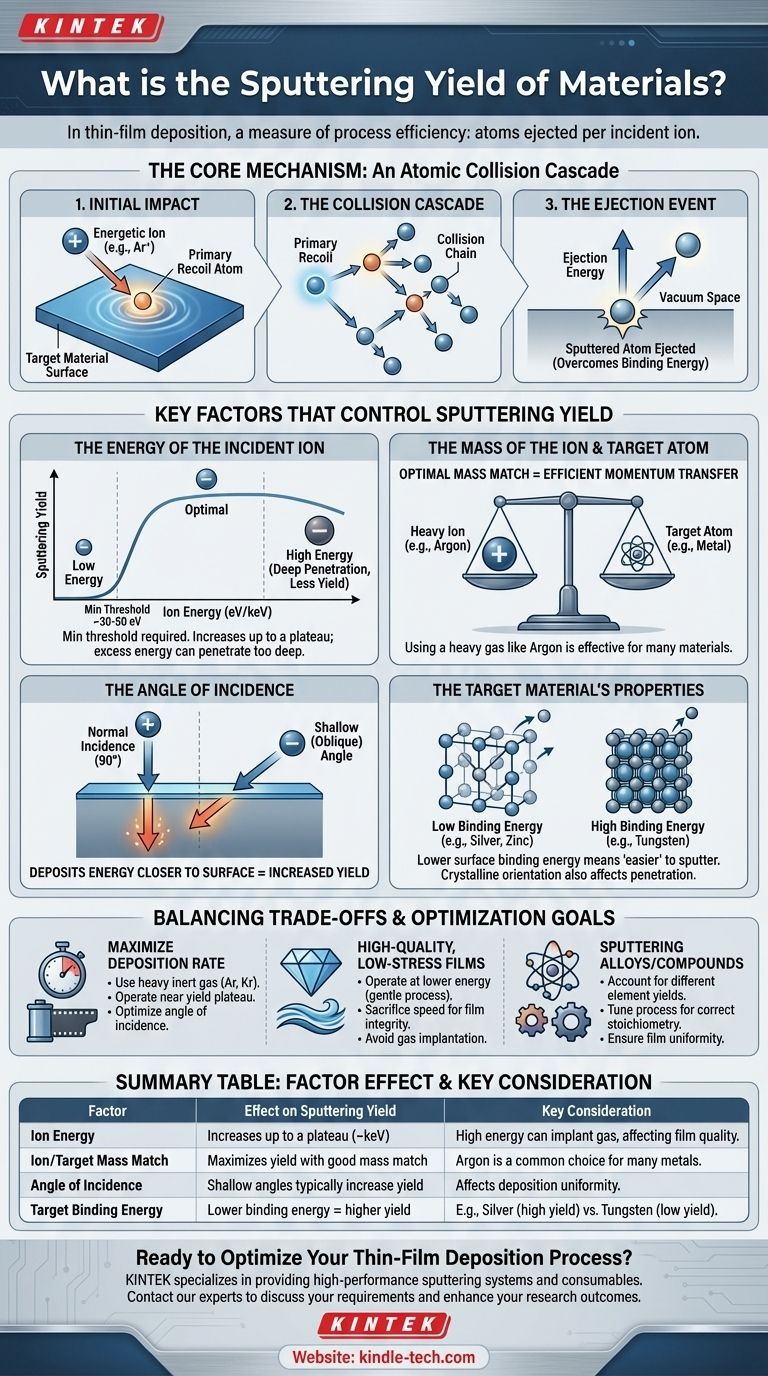

The Core Mechanism: An Atomic Collision Cascade

To understand what controls the yield, you must first understand the physical process. Sputtering is not a simple "billiard ball" collision where one ion knocks out one atom.

The Initial Impact

When a positive ion (typically from a gas like Argon) is accelerated and collides with the target, it transfers its kinetic energy to the atoms at the surface. This creates primary recoil atoms within the material's lattice.

The Collision Cascade

These primary recoil atoms, now energized, collide with other nearby atoms, which in turn collide with others. This creates a chain reaction, or a collision cascade, that rapidly distributes the initial impact energy throughout a small volume near the surface.

The Ejection Event

An atom is sputtered, or ejected, only if it is located at the very surface of the target and receives enough energy from the cascade in a direction pointing away from the surface. This energy must be sufficient to overcome the forces holding it in place.

Key Factors That Control Sputtering Yield

Several interdependent variables determine the efficiency of this energy transfer and, therefore, the final sputtering yield.

The Energy of the Incident Ion

There is a minimum energy threshold, typically 30-50 eV, required to overcome the target's binding energy and initiate sputtering.

Above this threshold, the yield generally increases with higher ion energy. However, at very high energies (e.g., above a few keV), the yield begins to plateau or even decrease because the ion penetrates too deeply, depositing its energy far below the surface where it cannot contribute to ejecting atoms.

The Mass of the Ion and Target Atom

The efficiency of momentum transfer is critical. Maximum energy transfer occurs when the mass of the incident ion closely matches the mass of the target atom.

Using a heavy sputtering gas like Argon is effective for many materials because its mass provides a good compromise for efficient momentum transfer to a wide range of common metal targets.

The Angle of Incidence

Ions striking the target at a shallow (oblique) angle tend to deposit more of their energy closer to the surface. This can significantly increase the sputtering yield compared to ions striking head-on (at normal incidence), which may drive their energy deeper into the material.

The Target Material's Properties

The surface binding energy of the target is a primary factor. This is the energy that holds the atoms together. Materials with lower binding energies, like zinc or silver, are "easier" to sputter and have higher yields than materials with very high binding energies, like tungsten.

For crystalline targets, the orientation of the crystal lattice also matters. If ions strike along an open "channel" in the crystal structure, they can penetrate deeply with fewer collisions, resulting in a lower sputtering yield.

Understanding the Trade-offs

Simply maximizing sputtering yield is not always the primary goal. The choice of parameters involves balancing competing factors.

Yield vs. Film Quality

Aggressively high ion energies that boost sputtering yield can also lead to the implantation of sputter gas (e.g., Argon) into the growing film. This can induce stress and negatively affect the film's electrical or mechanical properties.

The Practical Limits of Energy

Continuously increasing the power (and thus ion energy) to get a higher yield provides diminishing returns. The yield eventually plateaus, and the excess energy is converted into heat, which must be managed to avoid damaging the target or the sputtering system.

Process Stability

The sputtering process itself can alter the surface of the target over time, potentially changing its texture or composition. This can cause the sputtering yield to drift during a long deposition run, affecting the consistency and repeatability of the film.

How to Optimize for Your Goal

Your approach to controlling sputtering yield should be dictated by the desired outcome for your specific application.

- If your primary focus is maximizing deposition rate: Use a heavy inert gas (like Argon or Krypton), operate at an energy level just before the yield plateaus, and consider optimizing the target-to-substrate geometry to take advantage of the angle of incidence.

- If your primary focus is producing high-quality, low-stress films: It may be better to operate at a lower energy, sacrificing some deposition speed for a more gentle process with less risk of gas implantation or film damage.

- If your primary focus is sputtering alloys or compounds: You must consider that different elements in the target may have different individual sputtering yields, which can require careful process tuning to ensure the deposited film has the correct stoichiometry.

Ultimately, understanding sputtering yield empowers you to move from simply running a process to precisely engineering the outcome of your thin-film deposition.

Summary Table:

| Factor | Effect on Sputtering Yield | Key Consideration |

|---|---|---|

| Ion Energy | Increases up to a plateau (~keV) | High energy can implant gas, affecting film quality. |

| Ion/Target Mass Match | Maximizes yield with good mass match | Argon is a common choice for many metals. |

| Angle of Incidence | Shallow angles typically increase yield | Affects deposition uniformity. |

| Target Binding Energy | Lower binding energy = higher yield | E.g., Silver (high yield) vs. Tungsten (low yield). |

Ready to Optimize Your Thin-Film Deposition Process?

Understanding sputtering yield is key to balancing deposition rate with film quality for your specific application. Whether your goal is maximum throughput or producing high-purity, low-stress films, the right lab equipment is crucial.

KINTEK specializes in providing high-performance sputtering systems and consumables for laboratories. We can help you select the ideal configuration to achieve precise control over your deposition process.

Contact our experts today to discuss your requirements and discover how KINTEK's solutions can enhance your research and production outcomes.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Direct Cold Trap Chiller

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- Which is better carbon or graphite? Choose the Right Material for Your Application

- What are the specific requirements for incubation equipment used in the bioleaching of enargite? Ensure High-Performance Results

- Are thin films used as coatings on lenses? The Key to Superior Optical Performance

- Have other labs successfully stored samples at -70°C? Proven Long-Term Preservation for Biological Materials

- What is the difference between microwave and conventional pyrolysis? A Guide to Heating Mechanisms & Efficiency

- How does DC magnetron sputtering work? Achieve Superior Thin-Film Deposition

- What are the heat treatment processes in the heat treatment of steel? Master the Methods for Superior Material Properties

- What is a cheaper alternative to injection moulding? Find the Right Process for Your Volume