In short, an "autoclave 132" cycle refers to a sterilization process that operates at a temperature of 132 degrees Celsius (270°F). This is a higher-temperature, shorter-duration cycle compared to the more traditional 121°C setting. Its primary purpose is to achieve rapid sterilization, particularly for heat-resistant instruments.

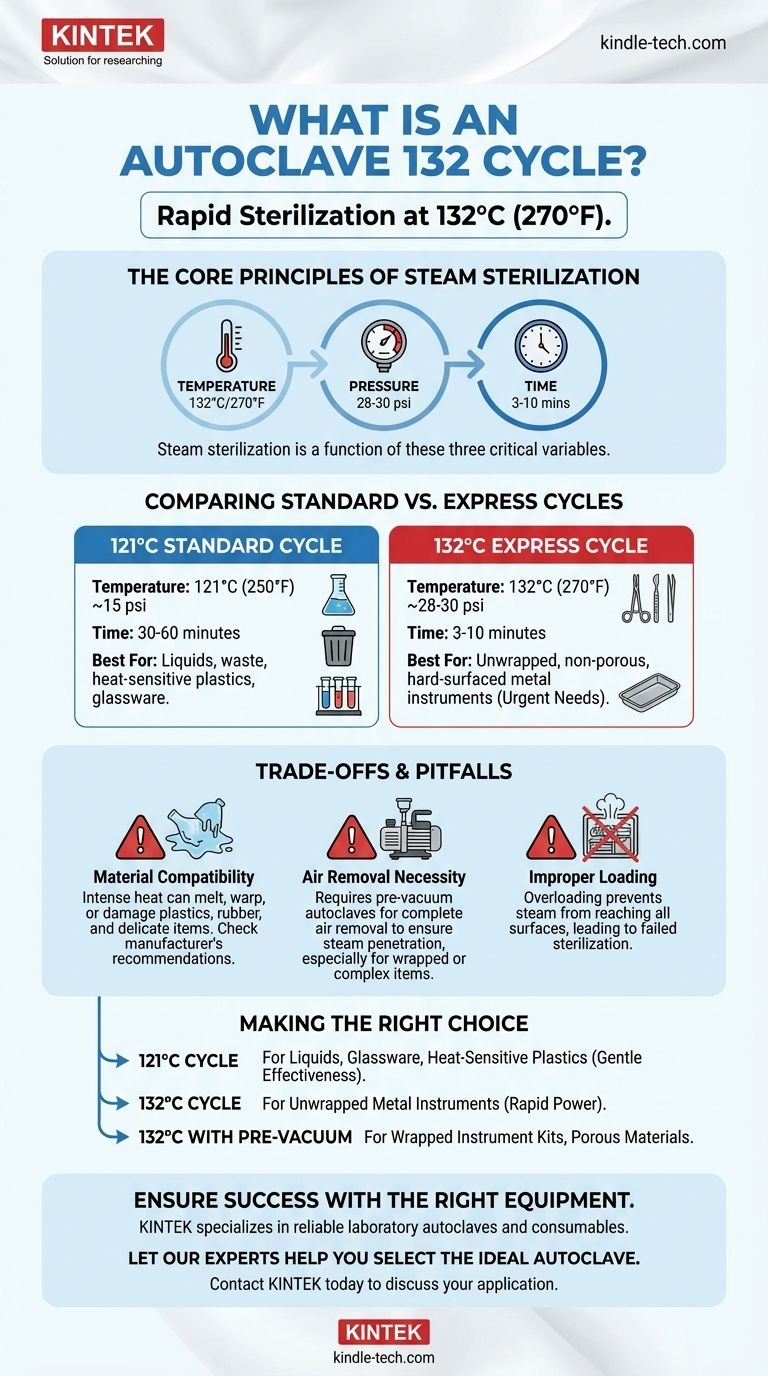

The core principle to understand is that steam sterilization is a function of three critical variables: temperature, pressure, and time. The 132°C cycle leverages a higher temperature and pressure to dramatically reduce the required sterilization time, but this speed comes with important trade-offs regarding material compatibility.

The Core Principles of Steam Sterilization

To understand the significance of the 132°C setting, you must first understand how an autoclave works. It's not simply a hot oven; it's a highly controlled pressure chamber designed to kill all microbial life, including resilient bacterial spores.

### The Role of Pressurized Steam

An autoclave's effectiveness comes from using saturated steam under pressure. At normal atmospheric pressure, water boils at 100°C (212°F). By increasing the pressure inside the chamber, the autoclave forces water to remain a liquid at higher temperatures, generating steam that is far hotter and has more energy.

This superheated, pressurized steam is exceptionally effective at transferring thermal energy to every surface it contacts.

### How Temperature Achieves Sterilization

The high temperature of the steam—whether 121°C or 132°C—is what actually kills microorganisms. It works by denaturing essential proteins and enzymes within the cells, causing irreversible damage and death.

Higher temperatures denature these proteins much faster, which is the key to the 132°C cycle's speed.

### The Relationship Between Pressure and Time

Pressure is the tool used to achieve the target temperature, while time is the duration needed at that temperature to ensure a complete kill.

For a 121°C cycle, the chamber is typically pressurized to about 15 psi (pounds per square inch). For a 132°C cycle, the pressure must be increased to approximately 28-30 psi. This increase in temperature and pressure creates a much more lethal environment for microbes, drastically shortening the required exposure time.

Comparing the Two Standard Cycles: 121°C vs. 132°C

Most modern autoclaves are built around these two standard cycles, each designed for different applications.

### The 121°C Cycle: The General Workhorse

This is the most common sterilization cycle. It balances effectiveness with material compatibility, making it suitable for a wide range of items.

It is the preferred method for sterilizing liquids, medical and laboratory waste, and heat-sensitive items like certain plastics and media. A typical cycle runs for 30 to 60 minutes once the target temperature is reached.

### The 132°C Cycle: The Express Option

This cycle is all about speed and efficiency, often called "flash sterilization" in medical contexts. A typical exposure time at this temperature can be as short as 3 to 10 minutes.

Because of its high heat, it is primarily used for unwrapped, non-porous, hard-surfaced instruments (like metal surgical tools) that can withstand the intense conditions.

Understanding the Trade-offs and Pitfalls

Choosing a cycle is not just about speed; it's about ensuring both sterility and the integrity of your equipment. Using the wrong cycle can have significant consequences.

### Critical Material Compatibility

The intense heat of a 132°C cycle can melt, warp, or damage many common plastics, rubber components, and delicate instruments. Always verify the manufacturer's recommendations for any item before autoclaving it at this temperature.

### The Necessity of Air Removal

For steam to sterilize, it must make direct contact with every surface. Air pockets are the enemy of sterilization.

The 132°C cycle is often performed in pre-vacuum autoclaves that actively pump all air out of the chamber before injecting steam. This ensures immediate and total steam penetration, which is critical for wrapped or complex items. In simpler "gravity displacement" autoclaves, this cycle should only be used for simple, unwrapped items.

### The Danger of Improper Loading

Overloading the autoclave or packing items too tightly can prevent steam from reaching all surfaces, regardless of the temperature setting. This can lead to a failed sterilization cycle, creating a significant safety risk.

Making the Right Choice for Your Goal

Selecting the correct cycle requires a clear understanding of your load and your objective.

- If your primary focus is sterilizing liquids, glassware, or heat-sensitive plastics: Use the standard 121°C cycle to ensure sterilization without damaging the items.

- If your primary focus is the urgent sterilization of unwrapped metal instruments: The 132°C cycle is the appropriate choice for its speed and effectiveness.

- If your primary focus is sterilizing wrapped instrument kits or porous materials: You must use a 132°C cycle in a pre-vacuum autoclave, following the device's specific time and drying parameters.

Ultimately, choosing the correct autoclave cycle is fundamental to guaranteeing safety and preserving the functional life of your equipment.

Summary Table:

| Cycle Type | Temperature | Pressure | Typical Exposure Time | Best For |

|---|---|---|---|---|

| Standard Cycle | 121°C (250°F) | ~15 psi | 30-60 minutes | Liquids, waste, heat-sensitive plastics/glassware |

| Express/Flash Cycle | 132°C (270°F) | ~28-30 psi | 3-10 minutes | Unwrapped, non-porous metal instruments (urgent needs) |

Ensure Sterilization Success with the Right Equipment

Choosing the correct autoclave cycle is critical for lab safety and efficiency. KINTEK specializes in providing reliable laboratory autoclaves and consumables designed to meet your specific sterilization needs, whether you require the gentle effectiveness of a 121°C cycle or the rapid power of a 132°C cycle.

Let our experts help you select the ideal autoclave for your laboratory's workflow and material requirements.

Contact KINTEK today to discuss your application and ensure your lab operates with precision and safety.

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- Are there any specific types of contamination that an autoclave cannot remove? Understanding the Limits of Steam

- What is the principle and structure of autoclave? Unlock the Power of High-Pressure Steam Sterilization

- What is the purpose of inserting armored thermocouples into an autoclave? Precision in Ammonothermal Process

- How do high-pressure autoclaves facilitate the synthesis of mesoporous hydroxyapatite powders? Optimize Your Biomaterials

- What is the role of a hydrothermal autoclave in HAp nanosheet synthesis? Engineered High-Pressure Crystallization

- What is an alternative to autoclaving for sterilizing heat sensitive materials? Compare Methods & Risks

- What is the most efficient method of sterilization? Match the Right Method to Your Materials

- What is the purpose and principle of autoclave? Achieve Absolute Sterilization with High-Pressure Steam