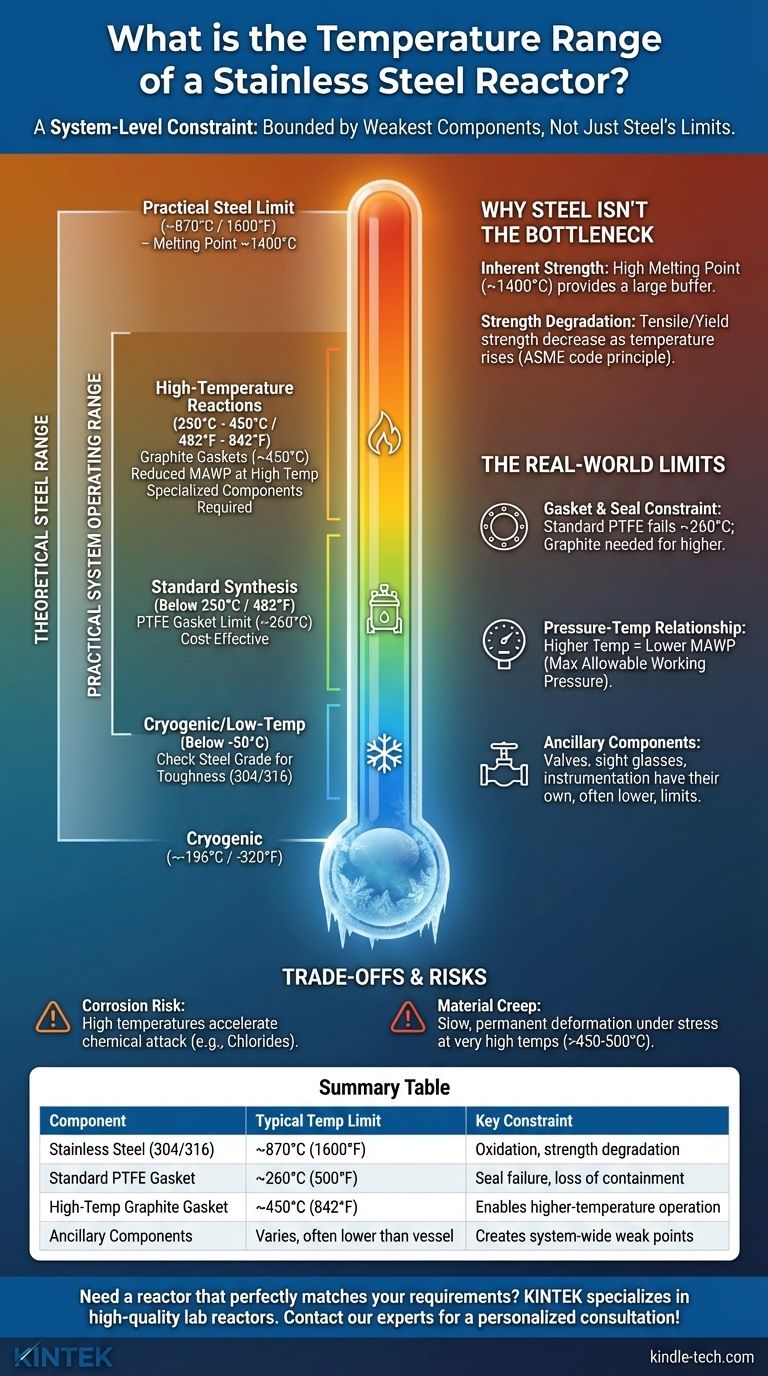

In principle, a stainless steel reactor can operate over a vast temperature range, from cryogenic levels near -196°C (-320°F) up to a practical limit of about 870°C (1600°F). However, the true operating range of a complete, functional reactor system is almost always much narrower. The system's rating is dictated by its weakest components—like gaskets and seals—and the inverse relationship between temperature and pressure rating, not the theoretical limits of the steel itself.

The maximum temperature of a stainless steel reactor is not a single number. It is a system-level constraint where components like gaskets, the vessel's pressure rating, and ancillary fittings typically impose a much lower and more realistic limit than the high melting point of the steel alloy.

Why Steel Itself is Rarely the Bottleneck

The Inherent Strength of Stainless Steel

The most common alloys for reactors, 316 and 304 stainless steel, have very high melting points, around 1400°C (2550°F). This provides an enormous buffer for most chemical processes.

These alloys maintain good mechanical properties well into high-temperature ranges. For example, 304 SS can be used for continuous service up to about 870°C (1600°F) before significant scaling (oxidation) becomes an issue.

How Temperature Reduces Mechanical Strength

While the melting point is high, the steel's strength begins to decrease at much lower temperatures. As temperature rises, the tensile strength and yield strength of the steel fall.

This means a vessel that is strong at room temperature becomes progressively "softer" and weaker as it heats up. This degradation is a core principle in pressure vessel design codes like ASME.

The Real-World Limits of a Reactor System

The Gasket and Seal Constraint

In most standard reactor configurations, the first component to fail from heat is the gasket. The gasket is the critical element that seals the reactor head to the vessel body.

Standard gaskets are often made of PTFE (Teflon), which has a maximum continuous service temperature of around 260°C (500°F). Pushing beyond this limit will cause the seal to fail, leading to a loss of pressure and containment.

For higher temperatures, specialized and more expensive gasket materials like flexible graphite are required, which can handle temperatures of 450°C (842°F) or higher.

The Pressure-Temperature Relationship

A reactor's pressure rating is not fixed. The Maximum Allowable Working Pressure (MAWP) is directly dependent on temperature. As you increase the operating temperature, the MAWP of the vessel goes down.

For example, a reactor rated for 100 bar at 20°C might only be rated for 80 bar at 300°C. This is because the vessel walls must be designed to contain the pressure safely with the steel's reduced strength at that higher temperature.

Ancillary Component Limits

A reactor is an assembly of many parts. Components like valves, rupture discs, sight glasses, and instrumentation probes all have their own specific temperature limits.

A glass sight port or a standard pressure transducer will almost certainly have a lower temperature rating than the steel vessel itself, creating another potential weak point in the system.

Understanding the Trade-offs and Risks

Corrosion Risk at High Temperatures

The "stainless" property of steel comes from a passive layer of chromium oxide on its surface. High temperatures can accelerate chemical attack that compromises this protective layer.

Certain chemicals, especially chlorides, can become much more aggressive at elevated temperatures, leading to pitting corrosion or even stress corrosion cracking in the steel. Your process chemistry dictates the true upper temperature limit for long-term reliability.

Material Creep

For processes that run continuously at very high temperatures (e.g., above 450-500°C), a phenomenon called creep becomes a concern. Creep is the slow, permanent deformation of the material under constant stress.

Vessels intended for high-temperature service must be designed with thicker walls or superior alloys to account for the long-term effects of creep and prevent eventual failure.

The Cost of High-Temperature Design

Designing a reactor for high-temperature operation is a significant cost driver. It requires specifying more expensive gaskets, specialized valves, potentially thicker vessel walls, and more robust insulation and heating systems. A standard, off-the-shelf reactor is not built for these conditions.

Making the Right Choice for Your Process

Before selecting a reactor, you must clearly define your target operating temperature and pressure. This information is more critical than simply choosing a material.

- If your primary focus is standard synthesis below 250°C (482°F): A standard 316L reactor with PTFE gaskets is often the most practical and cost-effective choice.

- If your primary focus is high-temperature reactions (250°C to 450°C): You must explicitly specify components rated for this range, such as graphite gaskets, and ensure the vessel's MAWP is certified for your target temperature.

- If your primary focus is cryogenic applications (below -50°C): You need to verify the steel grade (e.g., 304 or 316) is certified for low-temperature toughness to prevent brittle fracture.

Ultimately, defining your precise process requirements is the essential first step to engineering a safe, reliable, and effective reactor system.

Summary Table:

| Component | Typical Temperature Limit | Key Constraint |

|---|---|---|

| Stainless Steel (304/316) | ~870°C (1600°F) | Oxidation, scaling, and strength degradation |

| Standard PTFE Gasket | ~260°C (500°F) | Seal failure and loss of containment |

| High-Temp Graphite Gasket | ~450°C (842°F) | Enables higher-temperature operation |

| Ancillary Components (Valves, Probes) | Varies, often lower than vessel | Creates system-wide weak points |

Need a reactor that perfectly matches your temperature and pressure requirements? KINTEK specializes in high-quality lab reactors and equipment, serving diverse laboratory needs. Our experts can help you select or design a system with the right components—from gaskets to instrumentation—ensuring safety, reliability, and optimal performance for your specific chemical process. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS