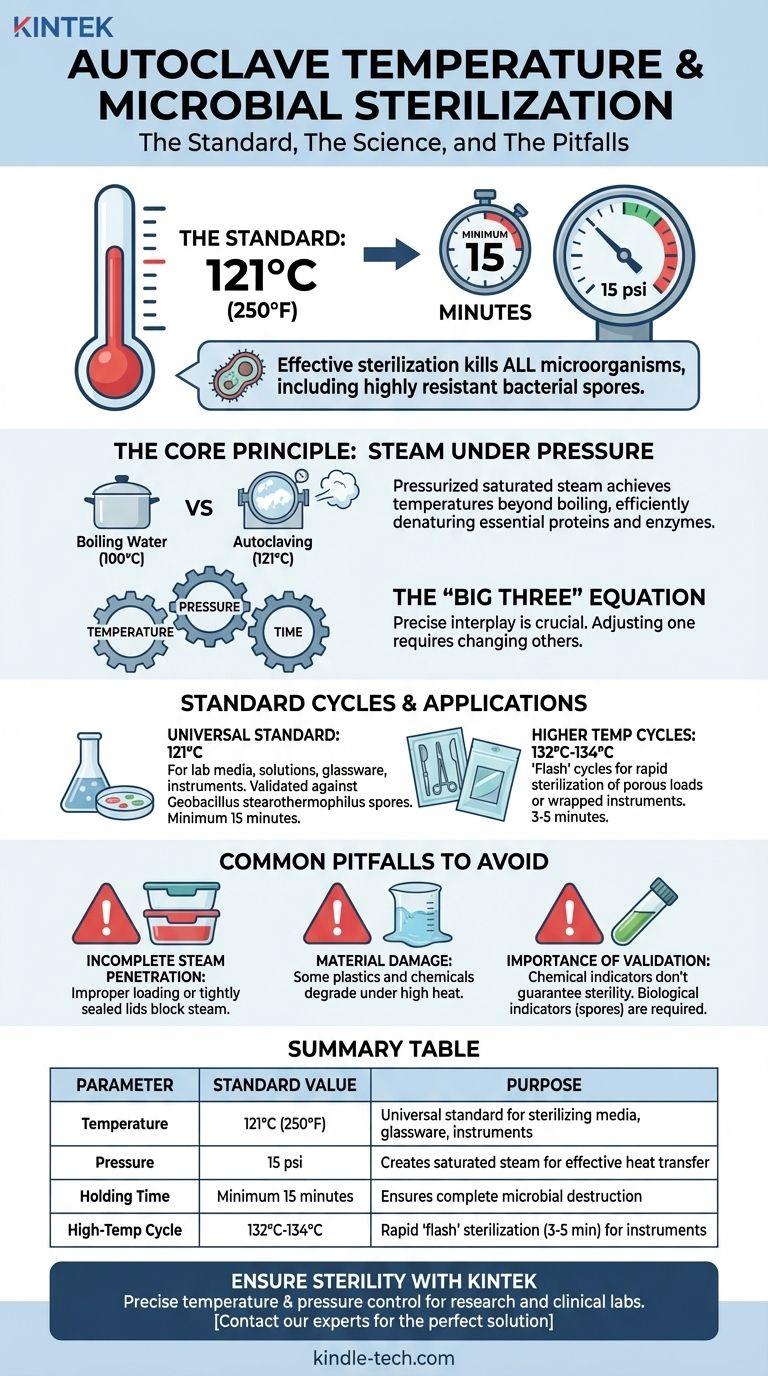

The standard temperature for general autoclaving is 121°C (250°F). This temperature is maintained for a minimum of 15 minutes to effectively sterilize materials by killing all microorganisms, including highly resistant bacterial spores. However, this number is only one part of a critical three-part equation required for successful sterilization.

The core principle of autoclaving is not just high temperature, but the use of pressurized saturated steam. It is the combination of intense heat, direct steam contact, and sufficient time that reliably destroys all forms of microbial life.

The Core Principle: Why Autoclaving Works

To understand why 121°C is the standard, it's essential to grasp the mechanism that makes an autoclave more effective than simply boiling.

Beyond Boiling Water

Boiling water at standard atmospheric pressure reaches 100°C (212°F). While this temperature can kill many vegetative bacteria, it is insufficient to eliminate highly resistant bacterial endospores, such as those from the Geobacillus or Bacillus genera.

These spores can survive boiling for extended periods, posing a significant risk of contamination.

The Power of Pressurized Steam

An autoclave functions like a sophisticated pressure cooker. By increasing the pressure inside its chamber, it allows water to exist as steam at temperatures well above the normal boiling point.

This saturated steam is the true sterilizing agent. It efficiently transfers thermal energy to any items in the chamber, denaturing the essential proteins and enzymes that all microorganisms rely on to live.

The "Big Three": Temperature, Pressure, and Time

Effective sterilization depends on the precise interplay of three factors. A change in one requires an adjustment in the others.

The most common and universally recognized standard for general-purpose sterilization is 121°C, at 15 psi (pounds per square inch) of pressure, for a minimum of 15 minutes. This duration is the holding time after the entire load has reached the target temperature.

Standard Autoclave Cycles and Their Purpose

While 121°C is the benchmark, different applications may call for different parameters.

The Universal Standard: 121°C

This cycle is the workhorse of most research and clinical labs. It is ideal for sterilizing laboratory media, aqueous solutions, utensils, glassware, and many common instruments.

Its effectiveness is validated against Geobacillus stearothermophilus spores, which are among the most heat-resistant organisms known. If a cycle can kill these spores, it is considered successful for sterilizing against all other common microbes.

Higher Temperature Cycles: 132°C - 134°C

For certain applications, a higher temperature can significantly shorten the required sterilization time. A cycle at 132°C (270°F), often used for porous loads or wrapped medical instruments, may only require a holding time of 3-5 minutes.

These are often called "flash" cycles, used in clinical settings for the rapid sterilization of surgical instruments. Extreme conditions, such as the inactivation of prions (the infectious proteins that cause Creutzfeldt-Jakob disease), may require even higher temperatures and much longer exposure times.

Common Pitfalls to Avoid

Simply setting the autoclave to 121°C does not guarantee sterility. Success depends on proper procedure and an understanding of potential failures.

Ineffective Sterilization

The most common failure is incomplete steam penetration. This can be caused by improperly loading the autoclave—packing items too densely prevents steam from reaching all surfaces.

Likewise, using containers with lids screwed on tight will block steam entirely. Lids must always be loosened to allow for steam exchange.

Damage to Materials

Not all materials can withstand the high temperatures and pressure of an autoclave. Many plastics, especially non-polypropylene types, will melt and deform.

Furthermore, some chemical reagents and complex media components (like vitamins, antibiotics, or certain sugars) can degrade under the intense heat, rendering them ineffective.

The Importance of Validation

Never assume a cycle was successful just because the machine completed it. Chemical indicators, like autoclave tape with stripes that change color, only show that a certain temperature was reached.

True validation requires biological indicators. These are vials containing Geobacillus stearothermophilus spores. After the cycle, the vial is incubated. If the spores were killed, there is no growth, confirming a successful sterilization.

Selecting the Correct Cycle for Your Application

Use your specific goal to determine the correct parameters for your autoclave run.

- If your primary focus is sterilizing general lab media and liquids: Use the standard 121°C cycle for at least 15 minutes, but increase the time for larger volumes (e.g., 30 minutes for a 2-liter flask) to ensure the core reaches temperature.

- If your primary focus is decontaminating biological waste: Extend the cycle time to 30-60 minutes at 121°C to guarantee full steam penetration through the dense and often unpredictable contents of a biohazard bag.

- If your primary focus is sterilizing hard, non-porous instruments: A 132°C flash cycle for 3-5 minutes can be effective, but always confirm the instrument is rated for this temperature.

- If you are working with heat-sensitive materials: Do not autoclave; you must use an alternative method like sterile filtration for liquids or ethylene oxide for plastics.

Mastering these parameters ensures your sterilization process is not just a routine, but a reliable scientific guarantee.

Summary Table:

| Parameter | Standard Value | Purpose |

|---|---|---|

| Temperature | 121°C (250°F) | Universal standard for sterilizing media, glassware, and instruments |

| Pressure | 15 psi | Creates saturated steam for effective heat transfer |

| Holding Time | Minimum 15 minutes | Ensures complete microbial destruction |

| High-Temp Cycle | 132°C-134°C | Rapid 'flash' sterilization (3-5 minutes) for instruments |

Ensure your lab's sterility and safety with reliable autoclaving equipment from KINTEK.

Whether you are sterilizing culture media, decontaminating waste, or preparing surgical instruments, precise temperature and pressure control is critical. KINTEK specializes in high-performance lab autoclaves and consumables designed to meet the rigorous demands of research and clinical laboratories.

We help you:

- Achieve guaranteed sterility with equipment validated for performance.

- Improve workflow efficiency with reliable and easy-to-use autoclaves.

- Protect your research and ensure compliance with industry standards.

Don't leave your sterilization to chance. Contact our experts today to find the perfect autoclave solution for your laboratory's specific needs!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What are the tips for using an autoclave? Ensure Effective Sterilization and Safety

- Why is a high-pressure hydrothermal synthesis autoclave necessary for MnO2 nanowires? Precision Catalyst Growth

- What is the temperature above 100 for autoclaving? Achieve Sterilization at 121°C

- What are the different sterilization methods for a microbiology lab? Ensure Reliable and Safe Experiments

- What are the common sterilization methods in a laboratory? A Guide to Choosing the Right Technique

- What is the most common hazard of using an autoclave? Prevent Severe Thermal Burns and Accidents

- What are the five uses of autoclave? From Sterilization to Industrial Processing

- What is an autoclave in microbiology? The Key to Sterile, Safe, and Valid Lab Results