In simple terms, twin screw extrusion is an advanced processing technique that uses two intermeshing, co-rotating screws inside a closed barrel to mix, compound, or react materials. Unlike simpler methods, the tight, self-wiping action of the screws ensures that all material is continuously processed and moved forward, resulting in exceptional efficiency and a highly uniform final product.

The fundamental advantage of twin screw extrusion lies in its design. The intermeshing screws actively clean each other, which eliminates dead spots and guarantees that every particle of material undergoes the same processing conditions.

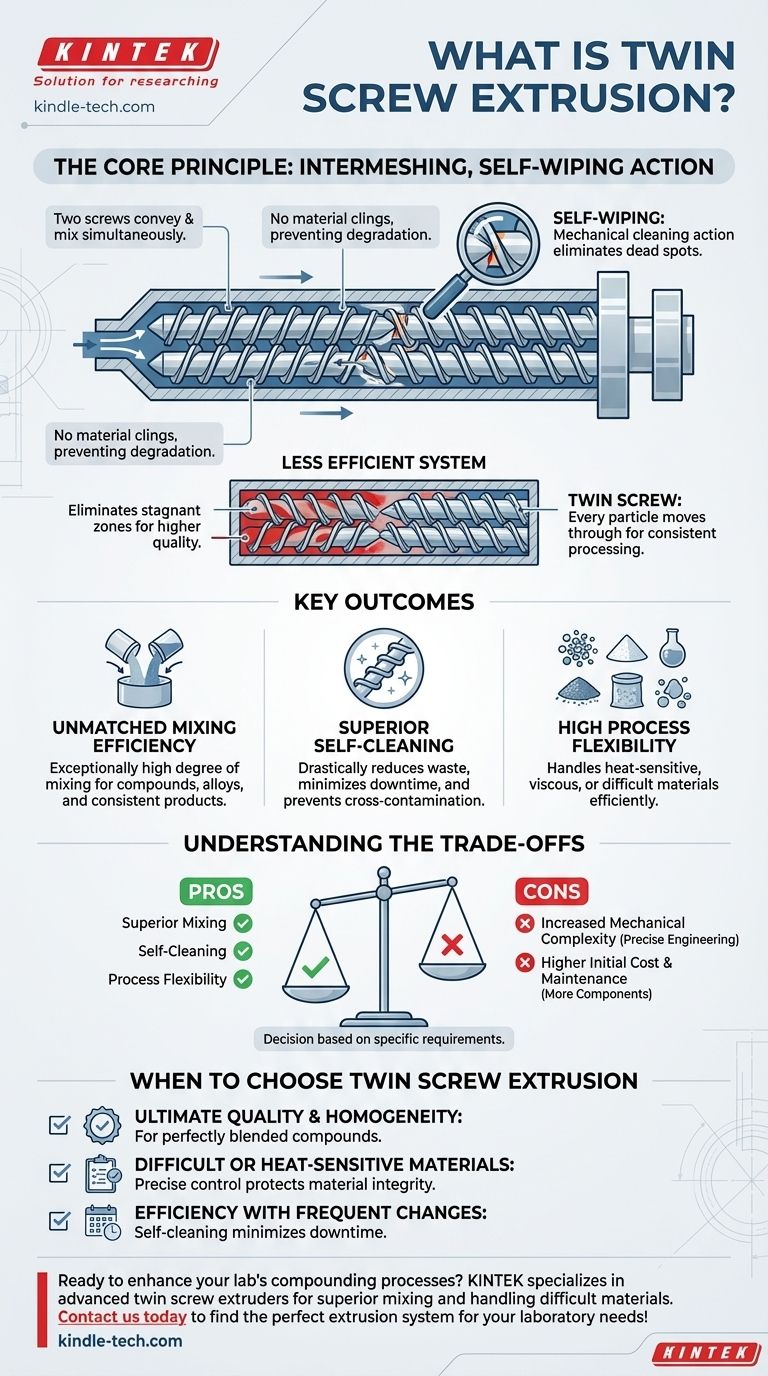

The Core Principle: Intermeshing, Self-Wiping Action

The unique capabilities of a twin screw extruder stem directly from the sophisticated interaction between its two core components. Understanding this mechanism is key to understanding its value.

How the Screws Work Together

A twin screw extruder features two screws that turn in the same direction within a precisely fitted barrel. As material is fed into the machine, the rotation of these screws simultaneously conveys it forward while mixing it.

The "Self-Wiping" Advantage

The flight of one screw constantly wipes the channel of the other. This mechanical cleaning action is the most important feature of the design.

This ensures that no material clings to the screw surfaces, preventing it from degrading due to prolonged exposure to heat.

Eliminating "Stagnant Zones"

In less efficient systems, "stagnant zones" can occur where material stops moving and gets over-processed or burnt. The self-wiping nature of twin screws eliminates these zones entirely.

Every particle is forced to move through the barrel, ensuring a consistent processing history for the entire batch and a higher quality, more uniform output.

Key Outcomes of the Twin Screw Design

The unique mechanical principle of twin screw extrusion leads to several critical process advantages that are difficult to achieve with other methods.

Unmatched Mixing Efficiency

Because the material is continuously being transferred between the two screws, the system provides an exceptionally high degree of mixing. This is crucial for applications like compounding plastics with additives, creating alloys, or producing highly consistent food products.

Superior Self-Cleaning

The self-wiping action results in a nearly perfect self-cleaning capability. When a production run is finished, very little material is left inside the barrel.

This drastically reduces waste, minimizes downtime between different product runs, and prevents cross-contamination.

High Process Flexibility

The efficient conveying and mixing allow twin screw extruders to handle a vast range of materials, including those that are heat-sensitive, viscous, or difficult to process in other systems.

Understanding the Trade-offs

While powerful, twin screw extrusion is not the universal solution for every application. Being aware of the trade-offs is essential for making an informed decision.

Increased Mechanical Complexity

The design, with its two intermeshing screws and corresponding gearbox, is inherently more complex than a single screw extruder. This intricacy requires more precise engineering and manufacturing.

Higher Initial Cost and Maintenance

The complexity and precision of twin screw systems typically result in a higher initial investment. The maintenance can also be more demanding due to the greater number of interacting components.

When to Choose Twin Screw Extrusion

The decision to use this technology should be driven by the specific requirements of your final product and process.

- If your primary focus is ultimate product quality and homogeneity: The superior mixing of a twin screw system is the definitive choice for creating perfectly blended compounds.

- If your primary focus is processing difficult or heat-sensitive materials: The precise control and elimination of stagnant zones protect material integrity.

- If your primary focus is production efficiency with frequent material changes: The self-cleaning properties minimize downtime and prevent contamination between batches.

Ultimately, twin screw extrusion is the premier technology for applications where precise control and exceptional mixing are non-negotiable.

Summary Table:

| Aspect | Key Feature | Benefit |

|---|---|---|

| Mixing | Intermeshing screws | Exceptional homogeneity and uniform product quality |

| Cleaning | Self-wiping action | Reduces waste, minimizes downtime, prevents contamination |

| Flexibility | Efficient conveying | Handles heat-sensitive, viscous, or difficult materials |

| Complexity | Precise engineering | Higher initial cost and maintenance, but superior performance |

Ready to enhance your lab's compounding and mixing processes? KINTEK specializes in advanced lab equipment, including twin screw extruders designed for superior mixing efficiency, self-cleaning, and handling of difficult materials. Our solutions help you achieve unmatched product uniformity and process flexibility. Contact us today to find the perfect extrusion system for your laboratory needs!

Visual Guide

Related Products

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Powerful Plastic Crusher Machine

- Three-dimensional electromagnetic sieving instrument

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

People Also Ask

- What is the purpose of a vulcanizing machine? Transform Rubber into High-Performance Parts

- What is the difference between extrusion and co-extrusion? Engineer Multi-Material Parts

- What are natural rubber sheets used for? Unlock Durability, Elasticity, and Vibration Damping

- What are the different types of internal mixers? Choose Between Tangential & Intermeshing Rotors

- What is the process of calendering? A Guide to High-Volume Plastic Film Production

- What is a calendering machine? Transform Material Surfaces with Precision

- What are the different types of powder mixers? Choose the Right Mixer for Your Materials

- What is an internal screw mixer? A Guide to Gentle, Efficient Powder Blending