In essence, an autoclave is used to sterilize items that can withstand high temperatures and moisture. This includes surgical instruments, laboratory glassware, culture media, aqueous solutions, certain plastics like polypropylene tubes and pipette tips, and biohazardous waste. The process relies on pressurized steam, making it unsuitable for heat-sensitive materials, oils, powders, or sharp carbon-steel instruments.

The effectiveness of an autoclave hinges on a single principle: its ability to use high-pressure steam to kill microorganisms. Therefore, only items that can withstand intense heat and moisture and allow for complete steam penetration are suitable candidates for this sterilization method.

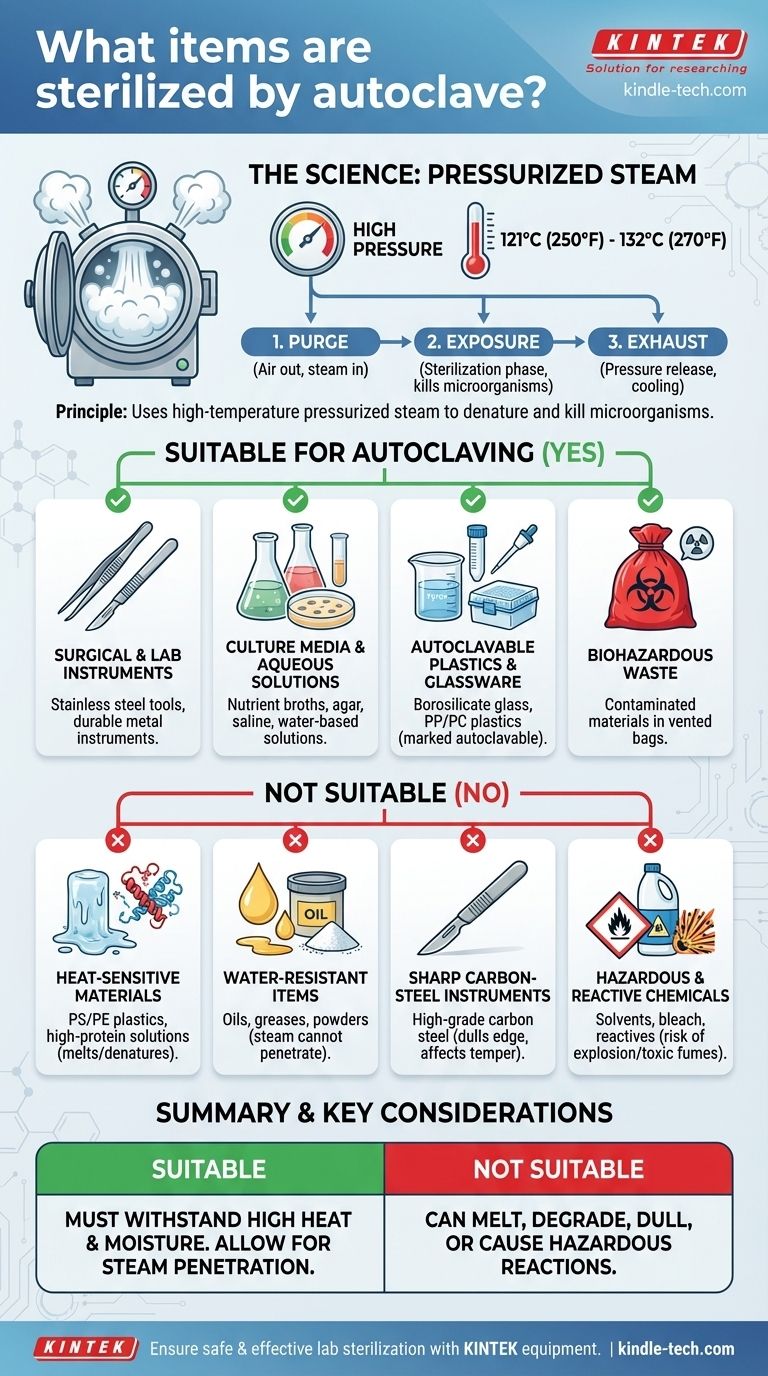

How Autoclave Sterilization Works

To decide what can be autoclaved, you must first understand the mechanism. An autoclave does not use dry heat; it uses pressurized steam, which is a far more effective method for heat transfer and microbial killing.

The Role of Pressurized Steam

An autoclave is essentially a highly controlled pressure cooker. By increasing the pressure inside the chamber, it raises the boiling point of water far above 100°C (212°F).

This high-temperature steam rapidly denatures the essential proteins and enzymes within microorganisms, rendering them non-functional and killing them. Common sterilization temperatures are 121°C (250°F) and 132°C (270°F).

The Three Phases of Sterilization

A typical autoclave cycle consists of three distinct phases:

- Purge Phase: Steam is injected into the chamber, displacing the cooler, less-effective air. Both temperature and pressure begin to ramp up.

- Exposure (Sterilization) Phase: The autoclave's control system maintains the target temperature and pressure for a prescribed duration. This is when the actual sterilization occurs.

- Exhaust Phase: The chamber is slowly vented, releasing pressure and allowing the sterilized items to begin cooling.

What Can Be Safely Autoclaved?

Based on the principle of steam sterilization, the following categories of items are routinely autoclaved in medical and research settings.

Surgical and Laboratory Instruments

Stainless steel surgical tools, forceps, and other metal instruments are ideal for autoclaving. They are durable and their surfaces are easily reached by steam.

Culture Media and Aqueous Solutions

Because the sterilization method is water-based, it is perfect for liquids. This includes nutrient broths, agar, saline, and other water-based solutions used in microbiology and cell culture.

Autoclavable Plastics and Glassware

Many common lab items are designed for this process. Borosilicate glassware (like Pyrex) and polypropylene (PP) or polycarbonate (PC) plastics are built to withstand the high temperatures without melting or degrading. This includes flasks, beakers, bottles, and specific tubes or pipette tip boxes.

Biohazardous Waste

Autoclaving is a primary method for decontaminating biological waste before disposal. This includes used petri dishes, cell culture flasks, and other materials contaminated with microorganisms. The waste must be placed in special, vented autoclave bags.

Understanding the Critical Limitations

Knowing what not to autoclave is as important as knowing what you can. Placing the wrong item in an autoclave can result in a failed sterilization cycle, damage to the equipment, or the release of hazardous fumes.

Heat-Sensitive Materials

Many materials simply cannot withstand the heat. Common polystyrene (PS) or polyethylene (PE) plastics will melt. Furthermore, high-protein solutions like vaccines, serums, or enzymes will be denatured and destroyed by the heat, requiring alternative methods like filtration.

Water-Resistant Items

Autoclaving is ineffective for substances that repel water. Oils, greases, and powders cannot be sterilized this way because the steam cannot penetrate them to kill microorganisms within the bulk material.

Sharp Instruments

While stainless steel instruments are fine, high-grade carbon steel scalpels and scissors can become dull. The high temperatures can affect the temper of the sharpened edge, reducing its cutting effectiveness.

Hazardous and Reactive Chemicals

Never autoclave flammable, reactive, corrosive, or toxic materials like solvents or household bleach. The high pressure and temperature can cause a violent reaction, leading to an explosion or the release of toxic gas.

Making the Right Choice for Your Materials

Use the material's properties as your guide. If you are ever in doubt, consult the manufacturer's documentation or your facility's safety officer.

- If your primary focus is routine sterilization of lab tools: Confirm your glassware is borosilicate and your plastics are marked as autoclavable (e.g., PP or PC) before proceeding.

- If your primary focus is decontaminating biohazardous waste: Ensure you use a designated autoclave bag with a vent to allow for steam penetration and never seal it completely.

- If your primary focus is handling sensitive liquids or chemicals: Immediately seek alternative methods like sterile filtration for heat-sensitive proteins or check safety data sheets before considering an autoclave for any chemical.

Ultimately, understanding the core principles of steam sterilization is the key to using an autoclave safely and effectively.

Summary Table:

| Category | Examples | Key Considerations |

|---|---|---|

| Suitable for Autoclaving | Stainless steel instruments, borosilicate glassware, polypropylene/polycarbonate plastics, aqueous solutions, biohazard waste in vented bags. | Must withstand high heat (121°C-132°C) and moisture; allow for steam penetration. |

| NOT Suitable for Autoclaving | Heat-sensitive materials (e.g., certain plastics, proteins), oils/powders, sharp carbon-steel instruments, flammable/reactive chemicals. | Can melt, degrade, dull, or cause hazardous reactions. |

Ensure your lab's sterilization is safe and effective with the right equipment.

KINTEK specializes in providing reliable lab equipment and consumables for all your sterilization needs. Whether you are setting up a new lab or optimizing your current processes, our expertise ensures you have the right autoclaves and autoclavable labware for dependable performance.

Contact us today to discuss your specific requirements and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What are the advantages and disadvantages of sterilization with an autoclave? Achieve Reliable Sterilization for Your Lab

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth

- How does a high-pressure rotary autoclave function during rice husk pretreatment? Optimize Biomass Conversion Efficiency

- What is the function of a stainless steel hydrothermal synthesis autoclave? Unlock Superior Nanocrystal Preparation

- What are the most important parameters for autoclave validation? Master Time, Temperature, and Pressure

- What is an autoclave sterilizer? Achieve Absolute Sterility with Steam and Pressure

- What is the daily maintenance of autoclave? Essential Steps for Safe and Reliable Sterilization

- What are the different types of autoclaves in microbiology? Gravity vs. Pre-Vacuum Explained