At its core, an autoclave is designed to sterilize materials that are both heat-stable and can be penetrated by steam. This includes a wide range of items common in medical and laboratory settings, such as surgical instruments, laboratory glassware, autoclavable plastics, culture media, and biohazardous waste. The process uses high-pressure steam to eliminate microorganisms, making it unsuitable for items that are damaged by heat or moisture.

The fundamental principle guiding what you can autoclave is simple: the material must withstand high temperatures (typically 121°C) and allow steam to penetrate it. Anything that melts, repels water, or is a volatile chemical is not a candidate for steam sterilization.

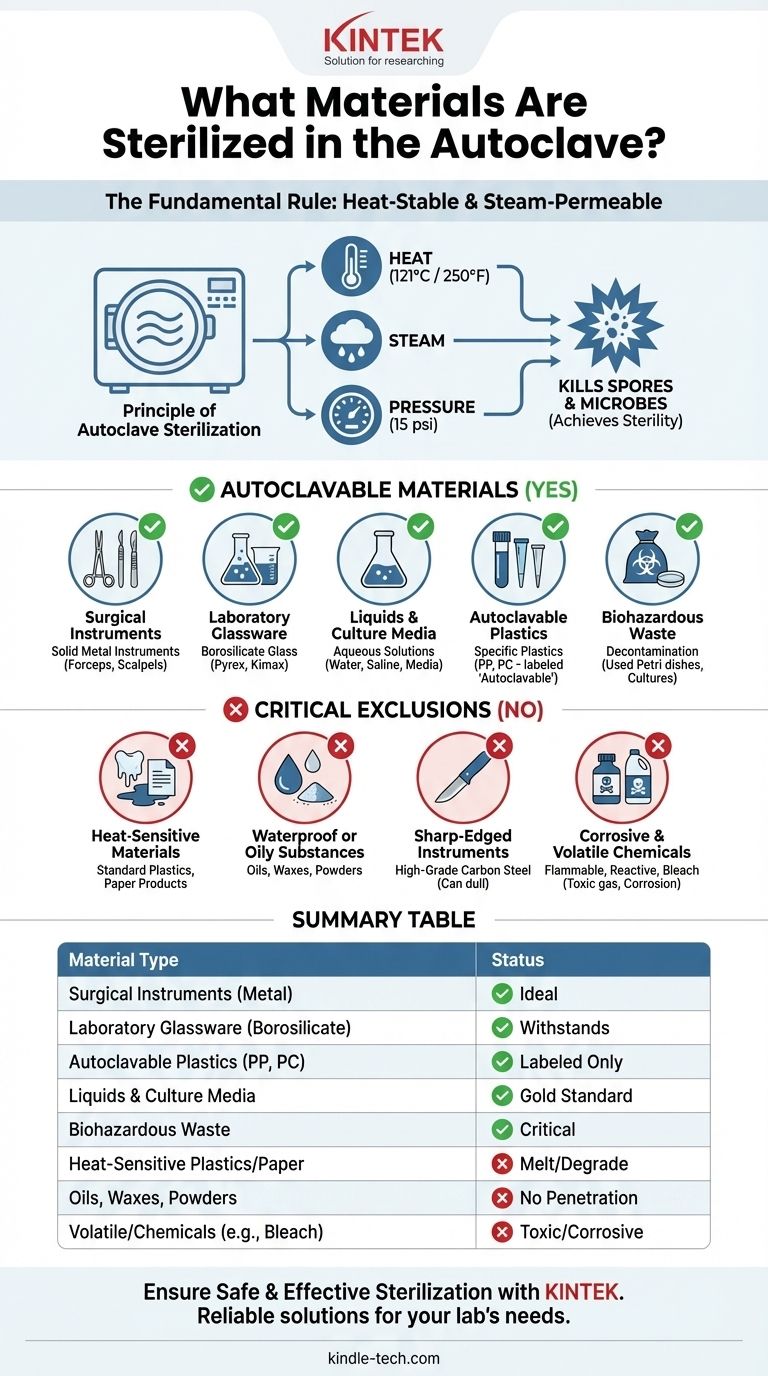

The Principle of Autoclave Sterilization

An autoclave is not simply an oven. Its effectiveness comes from a combination of three factors: heat, steam, and pressure. Understanding this mechanism is key to knowing which materials are appropriate.

Moist Heat Under Pressure

An autoclave operates by creating steam and then using pressure to raise its temperature well above the boiling point of water. A standard cycle runs at 121°C (250°F) under approximately 15 psi (pounds per square inch) of pressure.

This superheated, pressurized steam is incredibly effective at transferring heat energy to every surface it touches, rapidly killing all forms of microbial life.

The Target: Killing Spores

The primary goal of autoclaving is to achieve sterility, which means the complete elimination of all living microorganisms, including bacteria, viruses, fungi, and—most importantly—bacterial spores.

Spores are highly resistant, dormant structures that can survive boiling and many chemical disinfectants. The intense conditions inside an autoclave are specifically designed to destroy them by denaturing the essential proteins and enzymes they need to survive and reactivate.

A Breakdown of Autoclavable Materials

Based on the principle of steam sterilization, we can categorize suitable materials into several key groups.

Surgical and Medical Instruments

Solid metal instruments, such as forceps, scalpels (handles, not always the blades), and retractors, are ideal for autoclaving. The high heat effectively sterilizes their surfaces without causing damage.

Laboratory Glassware

Most laboratory glassware, particularly that made from borosilicate glass (like Pyrex or Kimax), is designed to withstand the thermal shock and high temperatures of the autoclave. This includes beakers, flasks, and test tubes.

Liquids and Culture Media

The autoclave is the gold standard for sterilizing liquids like water, saline solutions, and microbiological culture media. Because the process is based on moist heat, it is uniquely suited for sterilizing items that already contain water.

Autoclavable Plastics

Only specific types of plastic can survive autoclaving. Look for materials like polypropylene (PP) and polycarbonate (PC), which are often labeled as "autoclavable." This includes many modern pipette tips, containers, and tubes.

Biohazardous Waste

Autoclaves are critical for decontaminating laboratory and medical waste before disposal. This includes used petri dishes, cell cultures, and other materials contaminated with infectious agents, rendering them safe.

Critical Exclusions: What NOT to Autoclave

Knowing what to keep out of an autoclave is just as important as knowing what to put in. Placing the wrong material inside can result in failed sterilization, damage to the equipment, or a hazardous situation.

Heat-Sensitive Materials

Any standard plastic that is not specifically marked as autoclavable (e.g., polystyrene, polyethylene) will melt, creating a mess and potentially damaging the autoclave. Paper products will break down and become soggy and unusable.

Waterproof or Oily Substances

Steam cannot penetrate oils, waxes, or powders. Attempting to autoclave these materials will only heat their surface, leaving the interior unsterilized. They require dry heat sterilization or other methods.

Sharp-Edged Instruments

While many instruments are fine, those with very fine, sharp edges made of high-grade carbon steel can become dull from the high temperatures and moisture.

Corrosive and Volatile Chemicals

Never place flammable, reactive, or corrosive chemicals in an autoclave. This includes solvents and, most critically, household bleach (sodium hypochlorite). Heating bleach releases toxic chlorine gas and can severely corrode the stainless steel chamber of the autoclave.

Making the Right Sterilization Choice

Ultimately, selecting the correct sterilization method is about ensuring both safety and effectiveness for the specific material you are handling.

- If your primary focus is sterilizing reusable lab equipment: Autoclaving is the ideal method for borosilicate glassware, stainless steel tools, and marked autoclavable plastics.

- If your primary focus is preparing culture media or aqueous solutions: The autoclave is the definitive and most reliable method.

- If your primary focus is decontaminating biohazardous waste: Autoclaving is the industry standard for rendering biological waste non-infectious before disposal.

- If you are handling non-autoclavable plastics, oils, powders, or volatile chemicals: You must use an alternative method such as dry heat, chemical sterilization, filtration, or irradiation.

Choosing the right tool for the job is the foundation of safe and successful sterilization.

Summary Table:

| Material Type | Autoclavable? | Key Considerations |

|---|---|---|

| Surgical Instruments (Metal) | Yes | Ideal for steam sterilization; ensure they are heat-stable. |

| Laboratory Glassware (Borosilicate) | Yes | Withstands high temperatures and thermal shock. |

| Autoclavable Plastics (PP, PC) | Yes | Must be specifically labeled as "autoclavable." |

| Liquids & Culture Media | Yes | Gold standard for aqueous solutions. |

| Biohazardous Waste | Yes | Critical for decontamination before disposal. |

| Heat-Sensitive Plastics/Paper | No | Will melt or degrade; use alternative methods. |

| Oils, Waxes, Powders | No | Steam cannot penetrate; requires dry heat or chemicals. |

| Volatile/Chemicals (e.g., Bleach) | No | Risk of toxic gas release and equipment corrosion. |

Ensure your lab's sterilization is safe and effective with the right equipment from KINTEK. Whether you need durable autoclaves, autoclavable labware, or expert advice on handling heat-sensitive materials, KINTEK provides reliable solutions tailored to your laboratory's needs. Contact us today to learn how our products can enhance your sterilization protocols and protect your research integrity!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the function of a stainless steel hydrothermal synthesis autoclave? Unlock Superior Nanocrystal Preparation

- How long are autoclaved items sterile? Understanding Event-Related Sterility for Lab Safety

- Why is autoclaving the most effective? Harness the Power of Pressurized Steam for Absolute Sterility

- Why do we autoclave at 121 degree Celsius? The Science Behind Sterilization

- What are the 3 stages of autoclave sterilization? Master the Purge, Exposure & Exhaust Phases

- What is the role of autoclave in sterilization? Achieve Absolute Sterilization with High-Pressure Steam

- What is the recommended inspection frequency for laboratory autoclaves? Expert Maintenance Protocols for Safe Operation

- What type of instruments Cannot be autoclaved? Protect Your Equipment from Heat and Moisture Damage