In short, you can autoclave medical equipment made from materials that are stable under high heat and moisture. This primarily includes surgical instruments made of stainless steel, heat-resistant glassware, specific autoclavable plastics, culture media, and aqueous solutions. The key is that the material must withstand high-temperature steam without melting, degrading, or being damaged.

The decision to autoclave an item is not about the item itself, but about its fundamental material properties. Effective autoclaving depends on two non-negotiable conditions: the material must tolerate high-temperature steam without degrading, and it must allow for direct steam contact on all surfaces needing sterilization.

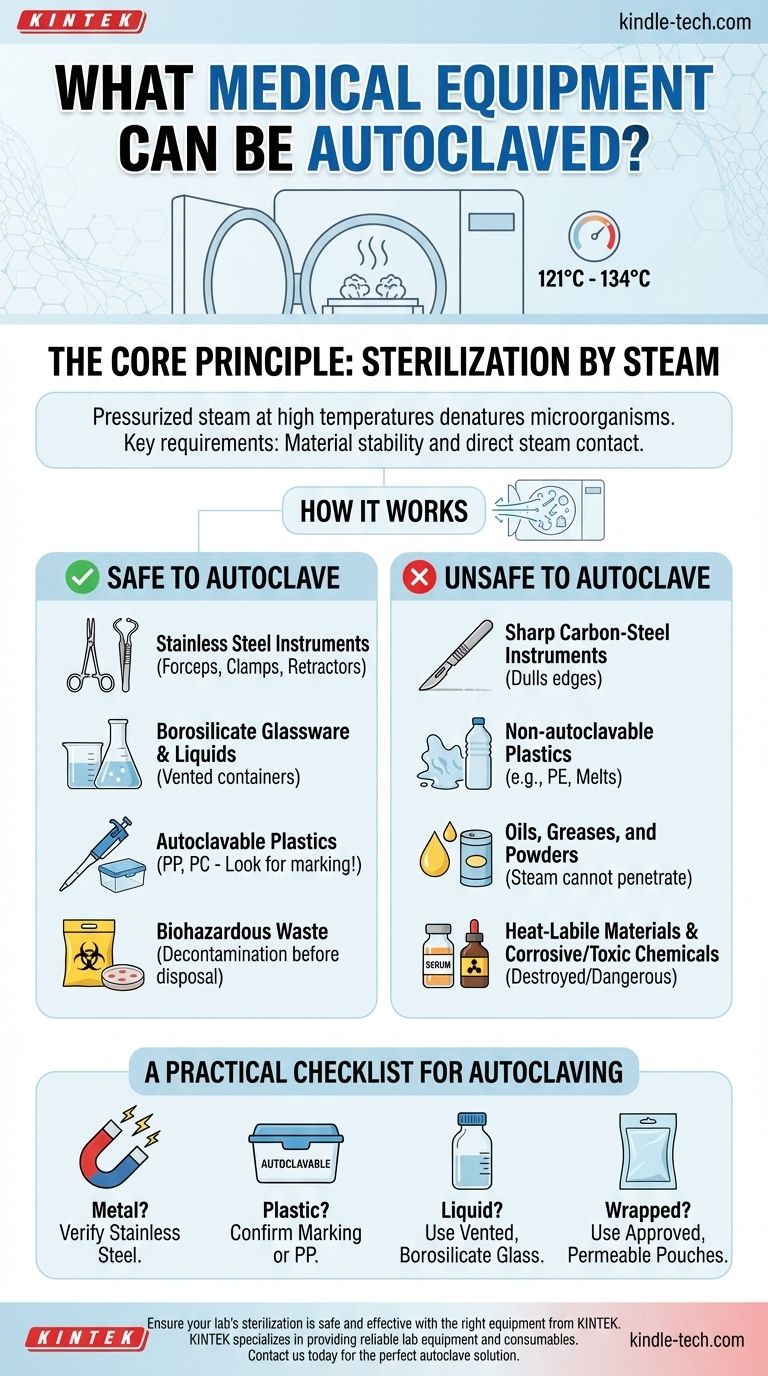

The Core Principle: Sterilization by Steam

How Autoclaves Work

An autoclave does not use dry heat. It creates a high-pressure environment that allows water to boil at temperatures well above 100°C (212°F), typically at 121°C or 134°C.

This pressurized steam is the active sterilizing agent. It carries a tremendous amount of thermal energy that is efficiently transferred to the items inside the chamber, denaturing the proteins of any microorganisms present.

The Importance of Direct Contact

For sterilization to be successful, this pressurized steam must make direct physical contact with every surface of the item.

If a material is waterproof or if items are packed in a way that creates air pockets, steam cannot penetrate. Those areas will not reach the required temperature and will not be sterilized.

What Can Be Safely Autoclaved?

Surgical and Dental Instruments

Most reusable surgical instruments, such as forceps, retractors, and clamps, are made of stainless steel precisely because it can withstand repeated autoclave cycles without corroding or losing its integrity.

Glassware and Liquids

Borosilicate glassware (like Pyrex) is designed to handle the extreme temperature changes of an autoclave cycle.

Aqueous solutions, water, and culture media can be effectively sterilized in an autoclave. It is critical, however, that the containers are vented to prevent the glass from shattering due to pressure changes.

Autoclavable Plastics and Consumables

Certain plastics, most commonly polypropylene (PP) and polycarbonate (PC), are formulated to be autoclavable. Always look for a marking on the product that explicitly states it is "autoclavable."

This category includes items like pipette tips, specific types of containers, and some plastic tubing. Common plastics like polyethylene (PE) will melt.

Biohazardous Waste

Autoclaving is a primary method for decontaminating and sterilizing biohazardous waste before disposal. The process effectively kills pathogens in items like used culture plates, gloves, and other contaminated lab materials.

Understanding the Trade-offs: What to Never Autoclave

This is not just about preventing damage; it is about ensuring safety and effective sterilization. Placing the wrong item in an autoclave can destroy the equipment, release toxic fumes, or result in a failed sterilization cycle.

Items Damaged by Heat or Moisture

Sharp-edged instruments, particularly those made from high-grade carbon steel, will become dull under high heat.

Heat-labile biological materials, such as certain serums, vaccines, and protein solutions, will be destroyed. These often require sterile filtration instead.

Materials Impervious to Steam

You cannot sterilize items that steam cannot penetrate. This is a common point of failure.

This list includes oils, greases, and powders. Because steam is water-based, it cannot mix with or penetrate these substances, leaving them unsterilized.

Heat-Sensitive and Reactive Materials

Many plastics will simply melt, potentially damaging the equipment and the autoclave itself. If a plastic item is not explicitly marked as autoclavable, assume it is not.

Never autoclave flammable, corrosive, radioactive, or toxic materials, including household bleach. The heat and pressure can cause unpredictable and dangerous chemical reactions.

A Practical Checklist for Autoclaving

To make a safe and effective choice, follow this simple decision-making process.

- If your item is a metal surgical instrument: Verify it is stainless steel; avoid autoclaving sharp carbon-steel blades, which will be dulled.

- If your item is plastic: Confirm it is explicitly marked "autoclavable" or made from polypropylene (PP); never autoclave unmarked plastics.

- If your item is a liquid: Ensure it is in vented, borosilicate (heat-proof) glassware and is not an oil, solvent, or corrosive chemical.

- If your item is wrapped or packaged: Use approved autoclave pouches or wraps that allow steam to penetrate, and never seal containers completely.

By understanding these core material principles, you can confidently ensure both the integrity of your equipment and the success of every sterilization cycle.

Summary Table:

| ✅ Safe to Autoclave | ❌ Unsafe to Autoclave |

|---|---|

| Stainless steel surgical instruments | Sharp carbon-steel instruments (dulls edges) |

| Borosilicate glassware (e.g., Pyrex) | Non-autoclavable plastics (e.g., polyethylene) |

| Autoclavable plastics (PP, PC) | Oils, greases, powders |

| Aqueous solutions & culture media | Heat-labile materials (serums, vaccines) |

| Biohazardous waste (e.g., used plates) | Flammable, corrosive, or toxic chemicals |

Ensure your lab's sterilization is safe and effective with the right equipment from KINTEK.

KINTEK specializes in providing reliable lab equipment and consumables, including autoclaves and autoclavable accessories, to meet the demanding needs of medical and research laboratories. Our products are designed to deliver precise, consistent performance for every sterilization cycle.

Contact us today to find the perfect autoclave solution for your laboratory and ensure your instruments are sterilized safely and efficiently.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

People Also Ask

- How long does autoclave liquid cycle take? The Truth About Sterilization Time & Safety

- What are the methods of validation of autoclave? Ensure Sterility with a 3-Pillar Approach

- What is the difference between types of autoclave? Choose the Right Sterilization Method for Your Lab

- What is the role of a hydrothermal autoclave in HAp nanosheet synthesis? Engineered High-Pressure Crystallization

- What critical environmental conditions does a high-pressure autoclave provide? Mastering FeCrAl Alloy Corrosion Testing

- What is the function of a high-pressure flowing autoclave in LWR testing for NITE-SiC? Simulating Reactor Conditions

- What are the applications of autoclave sterilization? Achieve Absolute Sterility in Medical, Lab, and Industrial Settings

- What is the temperature of autoclave 132? A Guide to High-Speed Sterilization Cycles