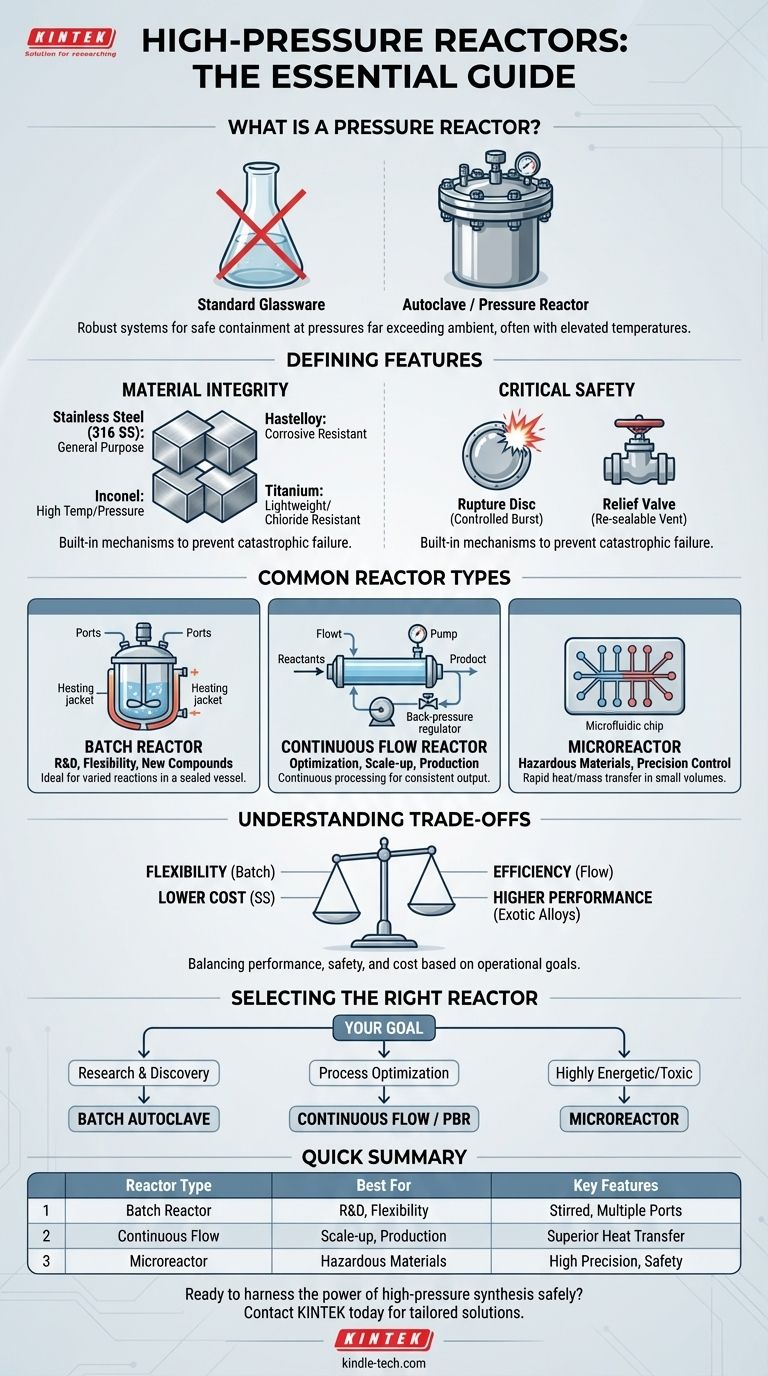

To conduct a high-pressure reaction, you need a specialized vessel known as an autoclave or, more broadly, a pressure reactor. Unlike standard laboratory glassware, these are robustly engineered systems designed to safely contain reactions at pressures far exceeding the ambient atmosphere, often in conjunction with elevated temperatures.

The term "high-pressure reactor" does not refer to a single piece of equipment. Instead, it describes a category of vessels where the specific choice of material, sealing mechanism, and design must be carefully matched to the reaction's required pressure, temperature, and chemical environment.

What Defines a High-Pressure Reactor?

The fundamental difference between a pressure reactor and standard lab equipment lies in material strength, system integrity, and built-in safety mechanisms.

Beyond Simple Glassware

Standard borosilicate glassware is not designed for significant internal pressure. Attempting to pressurize it creates an extreme safety hazard.

Pressure reactors are constructed from robust metals capable of withstanding high internal forces without deformation or failure.

The Role of Material Integrity

The choice of material is the first and most critical decision. It must not only be strong but also chemically inert under the reaction conditions.

- Stainless Steel (e.g., 316 SS): The workhorse for general-purpose applications due to its good strength, affordability, and decent corrosion resistance.

- Hastelloy: A nickel-based alloy used for superior resistance to highly corrosive substances like strong acids.

- Inconel: Another nickel-based alloy chosen for its ability to maintain structural integrity at very high temperatures and pressures.

- Titanium: Valued for its exceptional corrosion resistance, especially in chloride-containing environments, and its high strength-to-weight ratio.

Critical Safety Features

A pressure reactor is a system, not just a vessel. It must include non-negotiable safety components.

Rupture discs are designed to burst at a pre-set pressure, providing a controlled release to prevent catastrophic vessel failure. Pressure relief valves can reseal and are used to vent excess pressure during operation.

Common Types of High-Pressure Reactors

While designs vary, most high-pressure reactors fall into a few key categories based on their mode of operation.

The Laboratory Batch Reactor

This is the most common type for research and development. It consists of a sealed vessel with a removable head.

Key features include a heating/cooling jacket, an internal stirring mechanism (often a magnetic drive to avoid a leak-prone physical shaft seal), and multiple ports for sensors, reagent addition, and sampling.

Continuous Flow Reactors

For larger-scale or continuous manufacturing, a flow reactor is often used. Reactants are continuously pumped through a pressurized tube or packed bed (PBR).

Pressure is maintained by a back-pressure regulator at the system outlet. This design can offer superior heat transfer and safety for highly exothermic reactions compared to large batch systems.

Microreactors

A modern approach involves using micro-structured reactors with tiny channels. These systems offer extremely rapid heat and mass transfer.

Because of the very small internal volume, they provide significant safety advantages when working with hazardous materials or exploring unstable reaction conditions at high pressures and temperatures.

Understanding the Trade-offs

Choosing the right reactor involves balancing performance, safety, and operational goals. There is no single "best" solution.

Batch vs. Continuous Flow

Batch reactors offer flexibility for exploring different reactions in a single piece of equipment, making them ideal for R&D.

Continuous flow reactors are better suited for process optimization and large-scale production of a single product, offering better consistency and throughput.

Material Selection and Cost

More exotic alloys like Hastelloy or Titanium provide superior chemical resistance but come at a significantly higher cost than stainless steel.

Choosing an inadequate material to save money can lead to corrosion, product contamination, and dangerous equipment failure.

Sealing Mechanisms

The reactor's seal is often the limiting factor for its maximum pressure and temperature rating. O-rings are common for lower temperatures, while specialized metal-to-metal or graphite gaskets are required for more extreme conditions.

Selecting the Right Reactor for Your Application

Your choice must be driven by your end goal, the chemistry involved, and the scale of your operation.

- If your primary focus is research and new compound discovery: A versatile, stirred batch autoclave made of stainless steel or Hastelloy is the standard choice.

- If your primary focus is process optimization and scaling up a known reaction: A continuous flow or packed-bed reactor will provide better control and data relevant to production.

- If your primary focus is working with highly energetic or toxic materials: A microreactor offers unparalleled safety and precise control over reaction conditions.

By matching the reactor's design and materials to your specific chemical process, you can safely and effectively harness the power of high-pressure synthesis.

Summary Table:

| Reactor Type | Best For | Key Features |

|---|---|---|

| Batch Reactor | R&D, flexibility, new compound discovery | Stirred vessel, multiple ports, ideal for varied reactions |

| Continuous Flow Reactor | Process optimization, scale-up, production | Continuous processing, superior heat transfer, consistent output |

| Microreactor | Hazardous materials, high-precision control | Small internal volume, rapid heat/mass transfer, enhanced safety |

Ready to harness the power of high-pressure synthesis safely?

Choosing the right reactor is critical for the success and safety of your lab work. At KINTEK, we specialize in providing high-quality lab equipment, including a range of autoclaves and pressure reactors tailored to your specific chemical process, pressure requirements, and material compatibility.

Our experts can help you select the perfect system—whether you're in discovery research, process optimization, or working with challenging materials—ensuring you get the performance, durability, and safety features you need.

Contact KINTEK today to discuss your high-pressure reaction needs and find the ideal reactor for your laboratory.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth