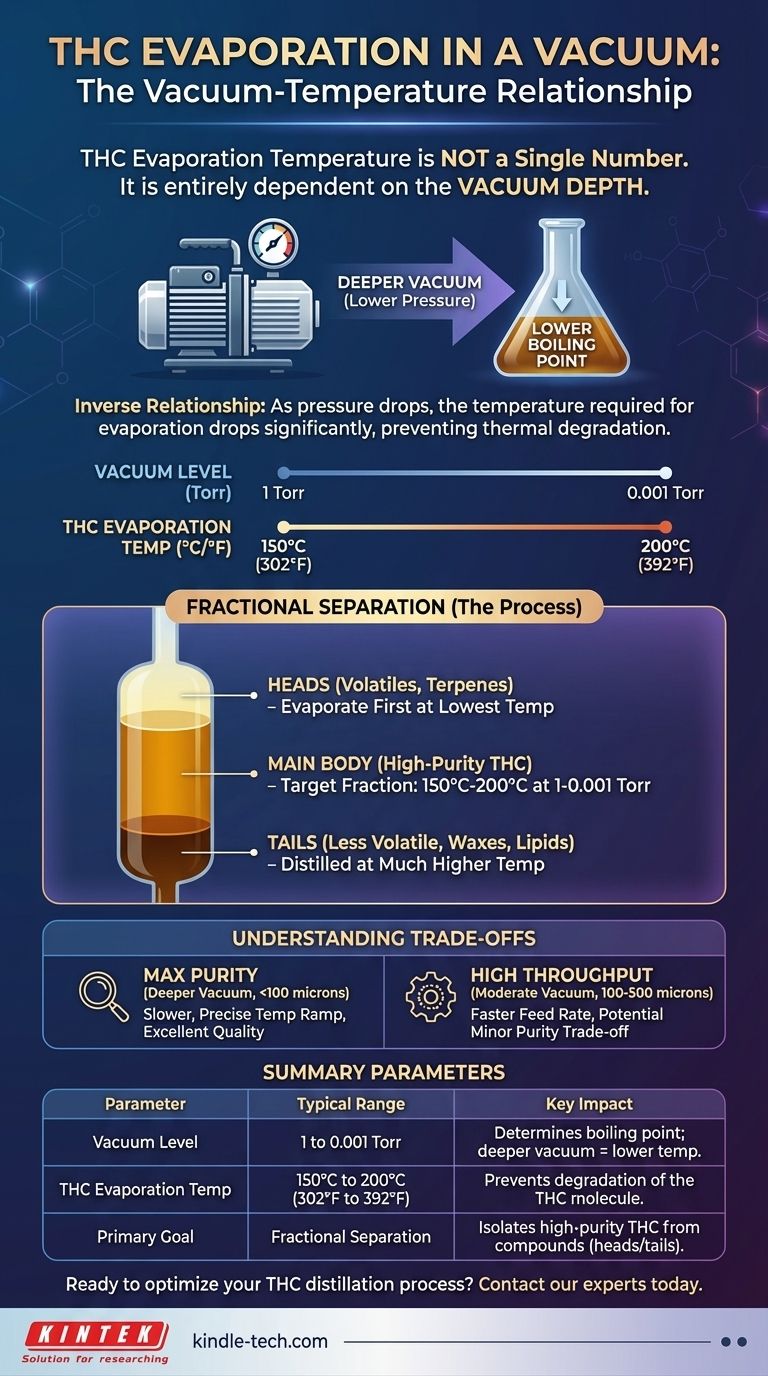

The evaporation temperature of THC in a vacuum is not a single number. It is entirely dependent on the depth of the vacuum applied. In the context of producing high-purity cannabis distillates, THC typically vaporizes between 150°C and 200°C (302°F and 392°F) under vacuum levels of 1 to 0.001 Torr.

The core principle to understand is that you are not just "evaporating" THC; you are performing fractional distillation. The goal is to manipulate both temperature and pressure to selectively separate cannabinoids from other compounds, and a lower pressure (deeper vacuum) directly lowers the temperature required to do so.

The Physics of Vacuum Distillation

Why Vacuum is Essential

The process of evaporating a material in a vacuum is a form of Physical Vapor Deposition (PVD). In the case of THC, we use vacuum to lower its boiling point.

At normal atmospheric pressure, THC has an extremely high boiling point (over 400°C), a temperature that would destroy the molecule. By removing the air pressure above the oil, we make it much easier for THC molecules to escape the liquid and become a vapor.

The Relationship Between Vacuum and Temperature

There is an inverse relationship between pressure and boiling point. As the vacuum level gets deeper (meaning the pressure gets lower), the temperature required for evaporation drops significantly.

This principle is why water boils at a lower temperature on a mountaintop, where air pressure is lower. Vacuum distillation simply takes this concept to a powerful extreme.

Preventing Thermal Degradation

The primary benefit of vacuum distillation is preventing heat damage to the THC molecule. At lower temperatures, THC is far less likely to degrade, isomerize into other cannabinoids like CBN, or oxidize.

This controlled, low-temperature process is critical for producing a high-quality, potent, and stable final product.

Practical Parameters for THC Distillation

Typical Vacuum Levels

In a laboratory or production setting, distillation is performed under a deep vacuum measured in Torr or microns.

Most short-path or wiped-film distillation of THC occurs in a pressure range of 1 to 0.001 Torr (which is equivalent to 1000 to 1 microns).

Corresponding Temperature Ranges

Within that vacuum range, different compounds will vaporize at different temperatures. This allows for fractional separation.

The "main body" fraction, which is rich in THC, is typically collected when the evaporator temperature is between 150°C and 200°C (302°F and 392°F). The exact temperature depends on the precise vacuum depth and the efficiency of the equipment.

Separating the Fractions

A successful distillation run involves separating the crude oil into three main parts, or "fractions."

- Heads: The most volatile compounds, like terpenes, evaporate first at the lowest temperatures.

- Main Body: This is the target fraction, containing the high-purity THC.

- Tails: The least volatile compounds, like other cannabinoids, lipids, and waxes, are left behind or distilled at much higher temperatures.

Understanding the Trade-offs

Vacuum Depth vs. Efficiency

Achieving a very deep vacuum (sub-100 microns) allows for the lowest possible distillation temperatures, which is excellent for preserving the quality of the THC.

However, deeper vacuum systems are more complex and can be slower. There is often a practical trade-off between the ultimate purity achieved and the overall throughput of the process.

The Critical Role of Temperature Control

Precision is key. If your temperature is too low, your evaporation rate will be poor, leading to low yield and inefficient separation.

If the temperature is too high, you risk degrading the THC into less desirable compounds like CBN, which reduces the value and potency of your final product. Stability in both temperature and vacuum is paramount.

Impact of Starting Material

The quality of your starting crude oil directly impacts the distillation process. Residual solvents, water, or a high percentage of waxes will interfere with your vacuum and lead to poor separation.

Properly winterized and prepared crude oil is essential for an efficient and successful distillation.

Making the Right Choice for Your Goal

To optimize your process, you must align your parameters with your primary objective.

- If your primary focus is maximum purity: Use a deeper vacuum (e.g., under 100 microns) and a slow, precise temperature ramp to carefully separate the heads, main body, and tails fractions.

- If your primary focus is high throughput: Utilize a stable, moderate vacuum (e.g., 100-500 microns) that allows for a faster and more continuous feed rate, accepting a potential minor trade-off in ultimate purity.

- If you are troubleshooting your process: Always check for vacuum leaks first. An unstable or poor vacuum is the most common cause of bad separation, low yield, and product degradation.

Mastering the interplay between vacuum and temperature is the key to producing high-quality THC distillate.

Summary Table:

| Parameter | Typical Range | Key Impact |

|---|---|---|

| Vacuum Level | 1 to 0.001 Torr | Determines boiling point; deeper vacuum = lower temperature. |

| THC Evaporation Temp | 150°C to 200°C (302°F to 392°F) | Prevents degradation of the THC molecule. |

| Primary Goal | Fractional Separation | Isolates high-purity THC from other compounds (heads/tails). |

Ready to optimize your THC distillation process for maximum purity and yield?

KINTEK specializes in precision lab equipment and consumables for the cannabis industry. Our expertise in vacuum distillation systems can help you achieve superior separation, prevent thermal degradation, and scale your production efficiently.

Contact our experts today to discuss how we can support your laboratory's specific needs and help you produce the highest quality distillate.

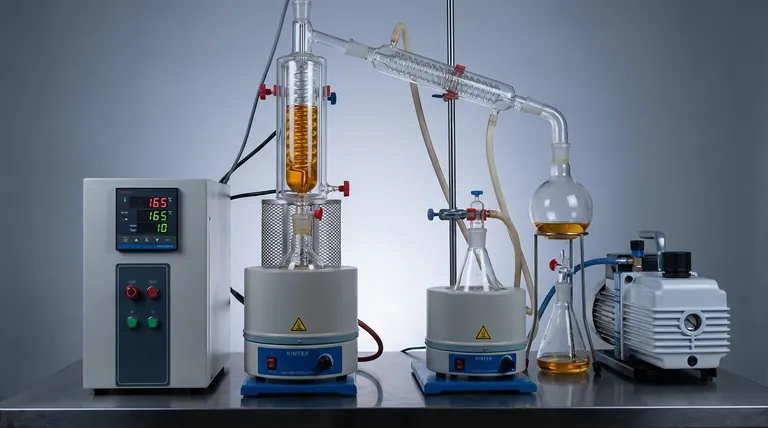

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts