In short, an autoclave is designed to sterilize items that can withstand high temperatures and direct contact with pressurized steam. This primarily includes surgical instruments made of stainless steel, laboratory glassware, specific types of autoclavable plastics like polypropylene, and certain liquids and culture media. The process relies on moist heat under pressure to effectively kill all forms of microbial life.

The suitability of an item for autoclaving comes down to a simple principle: it must tolerate temperatures of at least 121-134°C (250-273°F) and allow steam to penetrate and make direct contact with every surface that needs to be sterilized. If an object cannot meet both criteria, it is not a candidate for this method.

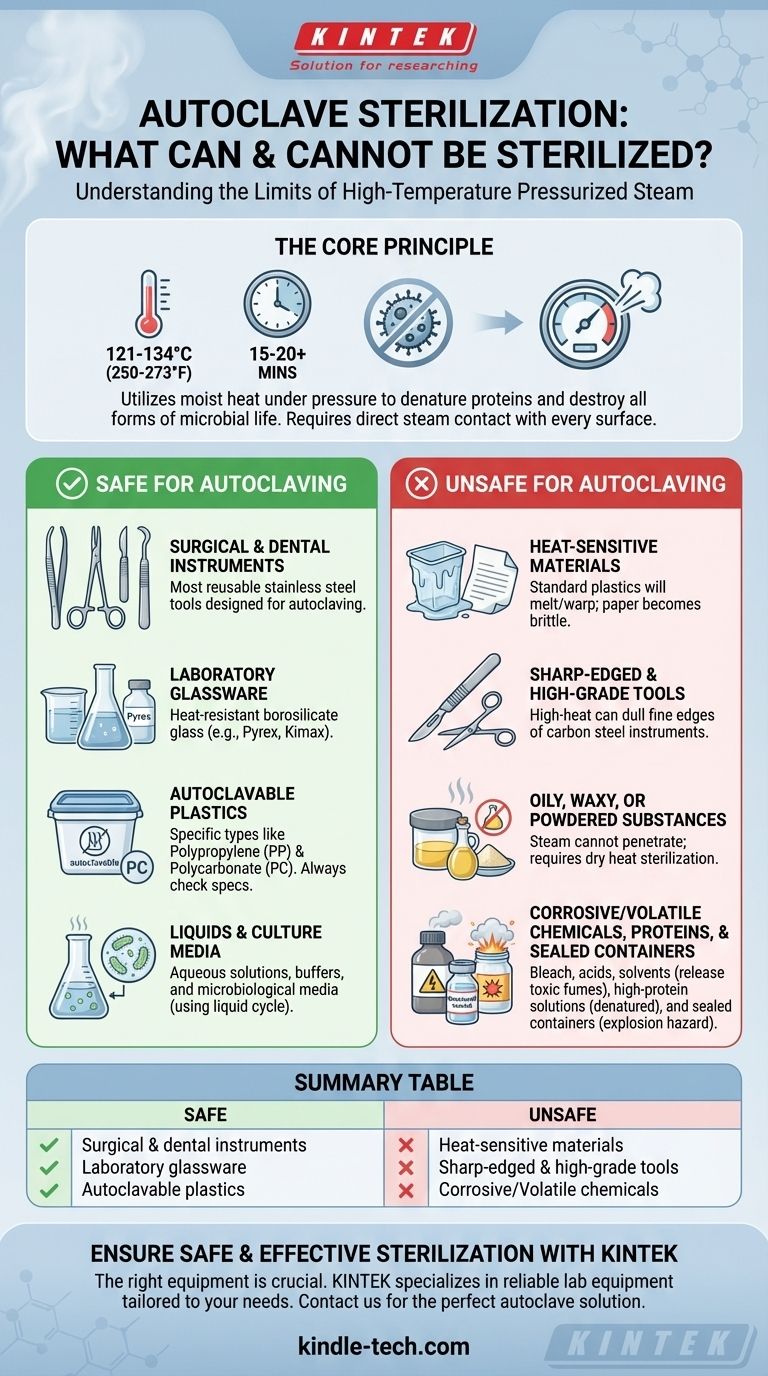

The Core Principle of Autoclave Sterilization

Autoclaving is the gold standard for sterilization in many medical and laboratory settings, but its effectiveness is rooted in a specific scientific process. Understanding this process is key to knowing what it can and cannot be used for.

It's All About Pressurized Steam

An autoclave does not simply "bake" items with dry heat. It uses pressurized steam to achieve and maintain temperatures well above the boiling point of water.

A typical cycle reaches 121°C (250°F) for at least 15-20 minutes. This combination of intense, moist heat and pressure creates an environment that denatures proteins and destroys the cellular structures of even the most resilient bacteria, viruses, and spores.

The Necessity of Direct Contact

For sterilization to be successful, steam must physically touch every surface. Air pockets or barriers that prevent steam penetration will leave areas unsterilized.

This is why proper loading and the material properties of the object itself are so critical. If steam cannot get to a surface, that surface will not be sterile.

What Materials Can Be Safely Autoclaved?

The following materials are routinely and safely sterilized using an autoclave, provided the correct cycle is chosen.

Surgical and Dental Instruments

Most reusable surgical and dental tools made of stainless steel are designed for autoclaving. This includes items like forceps, retractors, and scalpels handles.

Laboratory Glassware

Heat-resistant borosilicate glass, commonly known by brand names like Pyrex or Kimax, is ideal for autoclaving. This includes flasks, beakers, and bottles.

Autoclavable Plastics

Only certain types of plastic can withstand the high temperatures of an autoclave. Polypropylene (PP) and polycarbonate (PC) are common examples. Always check for the "autoclavable" symbol or manufacturer's specifications.

Liquids and Culture Media

Aqueous solutions, buffers, and microbiological culture media are frequently sterilized in an autoclave. This requires a specific "liquid" cycle that cools down slowly to prevent the liquid from boiling over.

Understanding the Limitations: What to Never Autoclave

Attempting to autoclave unsuitable materials is not only ineffective but can also damage the items and the autoclave itself. The following items should never be placed in an autoclave.

Heat-Sensitive Materials

Standard plastics will melt, warp, or degrade under autoclave conditions. Paper products can become brittle or damaged by the steam.

Sharp-Edged Instruments

While the body of a stainless steel instrument is fine, the finely honed edges of high-grade carbon steel scalpels or scissors can be dulled by the high heat, reducing their effectiveness.

Oily, Waxy, or Powdered Substances

Steam and oil do not mix. Steam cannot penetrate oily or waxy substances, leaving the microbes within completely unharmed. The same principle applies to anhydrous powders. These require dry heat sterilization.

Corrosive or Volatile Chemicals

Never autoclave items contaminated with bleach, acids, or volatile chemicals like solvents. These can release toxic fumes and severely corrode the autoclave's stainless steel chamber.

High-Protein Solutions

Certain sensitive biological materials, such as vaccines, serums, or solutions containing proteins like urea, can be denatured or destroyed by the intense heat, rendering them useless.

Sealed, Airtight Containers

Placing a sealed, rigid container in an autoclave is extremely dangerous. The pressure differential can cause the container to explode during the cycle, damaging the autoclave and creating a serious safety hazard. All containers must be vented.

Making the Right Sterilization Choice

Your choice of sterilization method must be guided by the material you are working with.

- If your primary focus is robust equipment (glassware, metal tools): Autoclaving is the gold standard, offering unparalleled reliability and efficiency when performed correctly.

- If your primary focus is heat-sensitive items (standard plastics, electronics): You must use a low-temperature alternative method, such as ethylene oxide (EtO) gas or vaporized hydrogen peroxide (VHP).

- If your primary focus is liquids or media: Use a dedicated liquid cycle in your autoclave, ensuring all containers are properly vented to prevent boil-over and potential explosions.

- If your primary focus is anhydrous materials (oils, powders): Autoclaving is completely ineffective; dry heat sterilization is the appropriate and necessary method.

Understanding the fundamental principles of steam sterilization empowers you to select the correct method, ensuring both safety and efficacy in your work.

Summary Table:

| Safe for Autoclaving | Unsafe for Autoclaving |

|---|---|

| Stainless steel instruments | Heat-sensitive plastics |

| Borosilicate glassware | Sharp-edged carbon steel tools |

| Polypropylene (PP) plastics | Oily, waxy, or powdered substances |

| Aqueous liquids & culture media | Corrosive or volatile chemicals |

| Polycarbonate (PC) plastics | High-protein solutions & vaccines |

| Sealed, airtight containers |

Ensure your lab's sterilization process is safe and effective with the right equipment from KINTEK.

Whether you're sterilizing surgical instruments, glassware, or specific plastics, using the correct autoclave is crucial for maintaining sterility and protecting your valuable materials. KINTEK specializes in providing reliable lab equipment and consumables tailored to your laboratory's unique needs.

Contact us today to find the perfect autoclave solution for your lab and achieve unparalleled sterilization performance!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What are the 4 types of autoclaves? Choose the Right Sterilization Method for Your Lab

- What is process monitoring in the context of a decontamination process? Ensure Safety and Compliance

- What is the function and limitation of chemical indicators in autoclave monitoring? Essential Sterilization Workflow Guide

- What precautions should be taken during autoclave in microbiology? Essential Safety Steps for Sterilization Success

- Why are high-temperature and high-pressure reactors (autoclaves) essential for friction and wear tests? Get Real Data

- Why is an autoclave the most effective sterilizer? Unlock the Power of Pressurized Steam for Guaranteed Sterility

- What is the primary function of a laboratory pressure steam sterilizer in dark fermentation? Boost Hydrogen Yield

- Can all materials be sterilized in the autoclave? A Guide to Safe & Effective Sterilization