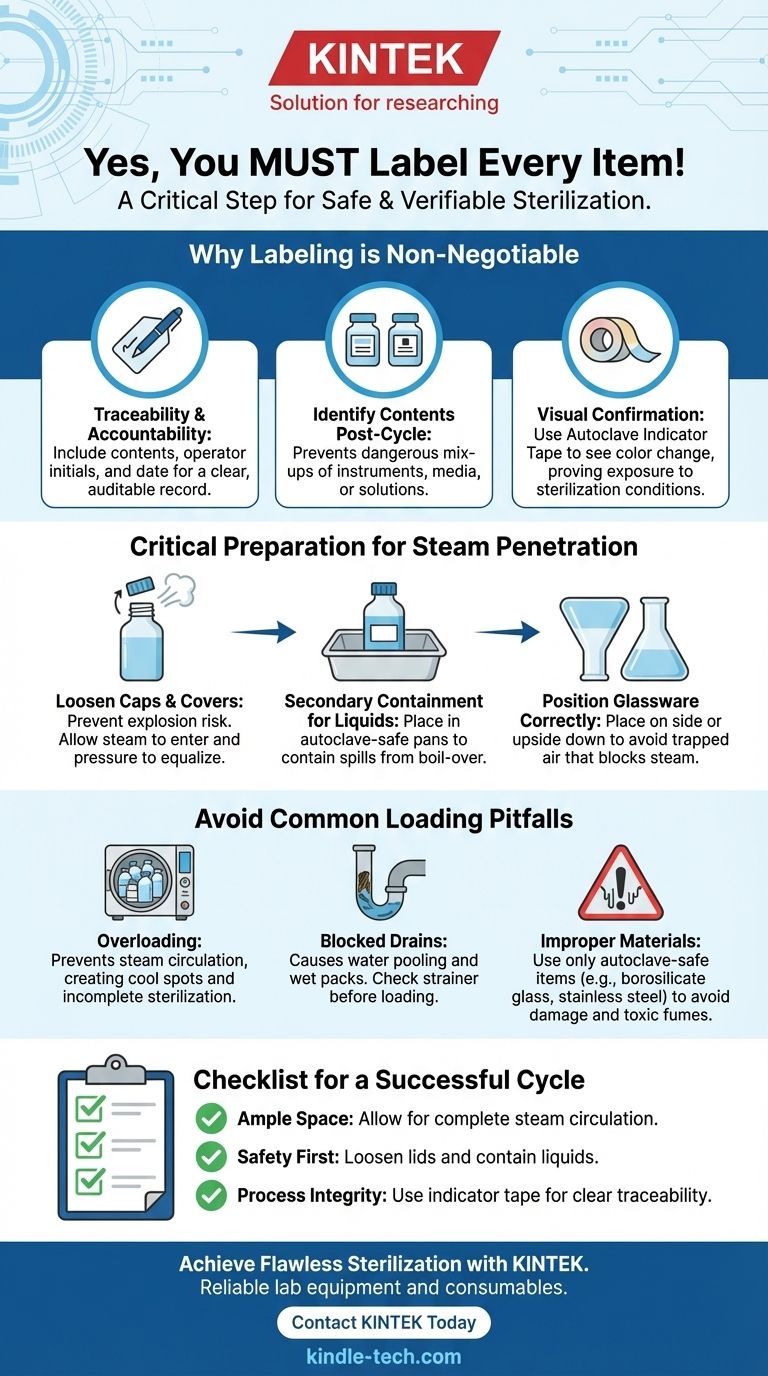

Yes, you must label every item before loading it into the autoclave. This is a critical and non-negotiable step in the sterilization process. Proper labeling ensures you can identify the contents after the cycle, track the sterilization date, and confirm that the item has been successfully processed, preventing dangerous mix-ups and ensuring procedural integrity.

While your question is about labeling, the deeper need is to ensure a safe and verifiably sterile outcome. Proper labeling is the first step in a meticulous preparation process that also involves arranging items correctly to guarantee that high-pressure steam can penetrate and sterilize everything in the load.

The Purpose of Pre-Sterilization Labeling

Labeling is not just for organization; it is a fundamental component of laboratory and clinical safety protocols. It provides essential information at a glance.

To Ensure Traceability and Accountability

A proper label should include the contents of the package or container, the name or initials of the operator, and the date of sterilization. This creates a clear and auditable record, which is essential for quality control and troubleshooting.

To Identify Contents Post-Sterilization

Many items look identical after being wrapped or bagged for autoclaving. A clear label prevents you from using the wrong instrument, media, or solution, an error that could compromise an entire experiment or procedure.

To Visually Confirm Processing

The best practice is to use autoclave indicator tape as part of your labeling. This specialized tape has markings that change color (e.g., from white to black) when exposed to the high temperatures of a sterilization cycle. This provides immediate visual proof that the item has been through the autoclave.

Preparing Items for Effective Steam Penetration

Beyond labeling, how you prepare and place your items in the chamber is the single most important factor in achieving sterility. The goal is to eliminate any barriers to steam.

Loosen All Caps and Covers

Never autoclave a container with a tightly sealed cap. As the contents heat up, pressure will build inside the container, creating a significant explosion risk. Loosen caps or use vented closures to allow steam to enter and pressure to equalize.

Use Secondary Containment for Liquids

Place bottles and flasks of liquid inside a shallow, autoclave-safe pan or tray. This will contain any spills that may occur from boil-over, preventing loss of material and making cleanup much easier and safer.

Position Glassware to Avoid Trapped Air

Empty glassware, such as beakers or bottles, should be placed on its side or upside down. This prevents air from being trapped inside, which would block steam from reaching and sterilizing the interior surfaces.

Understanding the Pitfalls of Improper Loading

Mistakes made during loading are the most common cause of sterilization failure. Avoiding these pitfalls is essential for a successful cycle.

The Danger of Overloading

The most frequent error is overloading the autoclave chamber. Items packed too tightly will prevent steam from circulating freely, creating cool spots where microorganisms can survive. Always leave ample space between all items.

The Failure of Blocked Drains

Before loading, always check that the chamber's drain strainer is clean and free of debris. A clogged drain can cause water to pool at the bottom of the chamber, which can lead to wet packs and incomplete sterilization for items at the bottom of the load.

The Risk of Improper Materials

Ensure everything you place in the autoclave is made of an autoclave-safe material (e.g., borosilicate glass, stainless steel, specific plastics like polypropylene). Using the wrong material can result in melted equipment, the release of toxic fumes, and damage to the autoclave itself.

A Checklist for a Successful Autoclave Cycle

Use these key principles to guide your preparation and ensure every cycle is safe and effective.

- If your primary focus is guaranteed sterility: Ensure there is ample space between all items and never overload the chamber to allow for complete steam circulation.

- If your primary focus is safety: Always loosen lids on containers and use secondary containment for liquids to prevent explosions and contain spills.

- If your primary focus is process integrity: Use autoclave indicator tape to label every item with its contents, the date, and your initials for clear traceability.

Meticulous preparation is not an optional step; it is the foundation of successful and safe sterilization.

Summary Table:

| Aspect | Key Consideration | Why It Matters |

|---|---|---|

| Labeling | Use autoclave indicator tape with contents, date, and initials. | Ensures traceability and provides visual confirmation of processing. |

| Loading | Avoid overloading; leave space for steam circulation. | Prevents cool spots and guarantees complete sterilization. |

| Liquids | Loosen caps and use secondary containment. | Prevents explosions and contains boil-overs for safety. |

| Glassware | Place on its side or upside down. | Prevents trapped air, allowing steam to sterilize all surfaces. |

Achieve Flawless Sterilization with KINTEK

Proper autoclave preparation is the foundation of lab safety and integrity. KINTEK specializes in providing the reliable lab equipment and consumables you need for successful sterilization cycles, including autoclave-safe containers and indicator tapes.

Let our experts help you optimize your processes. Contact KINTEK today to ensure your lab operates with the highest standards of safety and efficiency.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the size of a laboratory autoclave? A Guide to Choosing the Right Capacity

- What is important about loading an autoclave? Achieve Reliable Sterilization with Proper Technique

- Why is a High-temperature and High-pressure Autoclave necessary for zirconium alloy testing? Ensure Nuclear Safety.

- Why is a high-pressure helium injection system used? Ensure Accurate Sample Recovery in Autoclaves

- What specific reaction conditions does a PTFE-lined autoclave provide for NVP/C synthesis? Optimize Battery Cathodes

- Why is autoclave maintenance important? Ensure Sterilization Efficacy and Safety

- Is autoclave a lab equipment? Essential Sterilization for Reliable Science

- What are the common sterilization methods in a laboratory? A Guide to Choosing the Right Technique