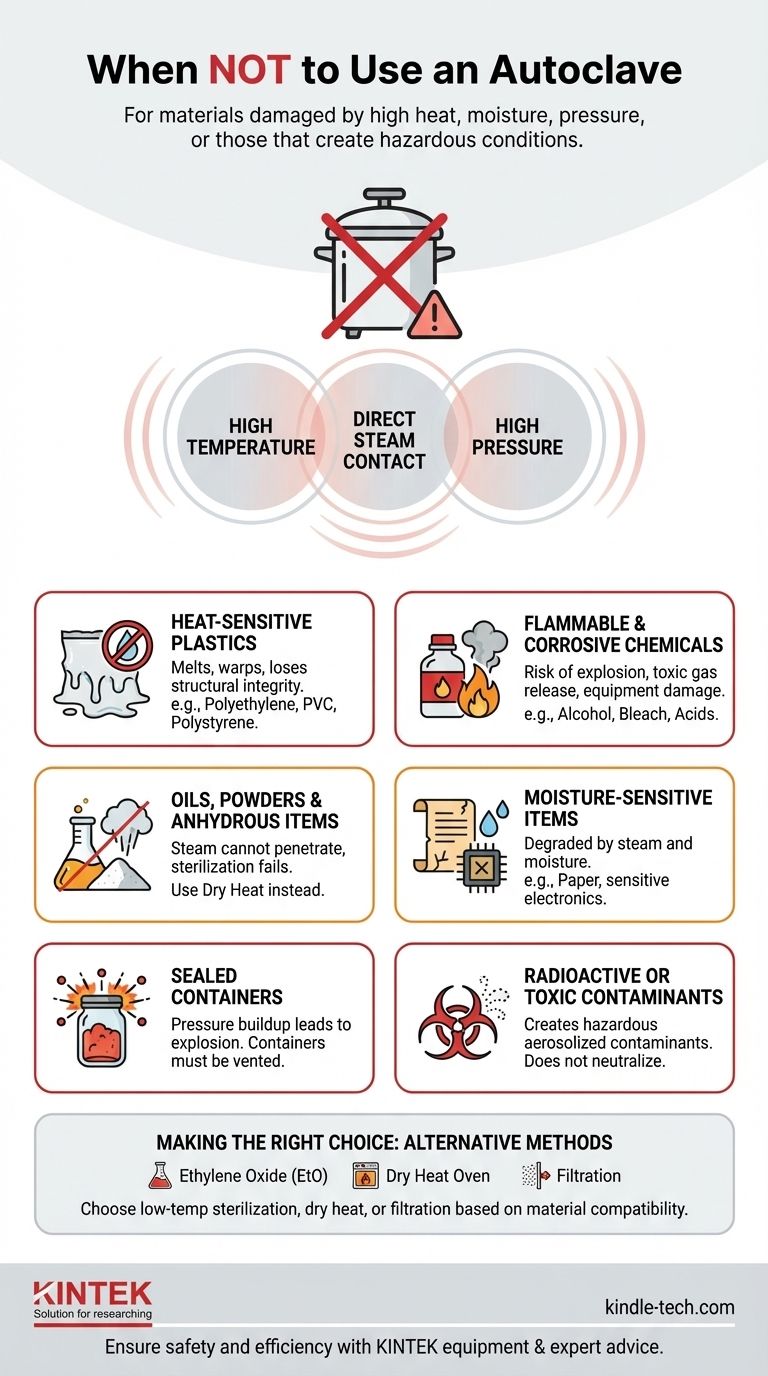

Ultimately, an autoclave should not be used for any material that can be damaged by high heat, moisture, and pressure, or for substances that can create hazardous conditions during the process. This includes heat-labile plastics, flammable or corrosive chemicals, and materials that cannot be penetrated by steam, such as oils and powders.

The core principle to remember is that an autoclave's sterilizing power—high-temperature saturated steam—is also its primary limitation. Any item that cannot withstand temperatures of at least 121°C (250°F) or that is damaged by direct moisture is not a candidate for autoclaving.

Why Autoclaves Have Limitations

To understand what not to autoclave, you must first understand how an autoclave works. The process relies on a combination of three factors: high temperature, direct steam contact, and high pressure. If an item is incompatible with any of these, sterilization will either fail or destroy the item.

The Impact of High Temperature

Autoclaves typically operate at 121°C or higher, a temperature sufficient to melt, warp, or permanently damage many common materials.

Heat-sensitive (heat-labile) products are the most common category of items that cannot be autoclaved. This includes many polymers and plastics that will lose their structural integrity.

The Requirement of Steam Penetration

Sterilization is achieved when saturated steam directly contacts every surface of an item. If steam cannot penetrate, the item will not be sterile.

This is why materials like oils, powders, and items wrapped in impermeable coverings are unsuitable. The steam simply cannot reach the microorganisms to kill them. Similarly, water-repellent materials can create air pockets that prevent sterilization.

The Dangers of Volatile or Corrosive Chemicals

Autoclaving certain chemicals is extremely hazardous. The high heat can cause them to vaporize, creating toxic or flammable fumes within the lab.

Materials like bleach (sodium hypochlorite) will corrode the stainless steel chamber of the autoclave and release harmful chlorine gas. Solvents and other volatile compounds present a significant explosion risk.

Common Materials Unsuitable for Autoclaving

Based on these principles, you can identify specific materials that must be sterilized using alternative methods.

Heat-Sensitive Plastics

While some plastics like polypropylene are autoclavable, many are not. Common examples include polyethylene, PVC, and polystyrene, which will melt into a useless mass. Always check the plastic's recycling code or manufacturer specifications.

Flammable and Corrosive Solutions

Never autoclave flammable liquids (e.g., alcohol, solvents) or corrosive chemicals (e.g., acids, bases, bleach). The risk of explosion and toxic gas release is unacceptably high and will damage the equipment.

Oils, Powders, and Anhydrous Items

These materials are "anhydrous," meaning they contain no water. Steam cannot effectively penetrate them, rendering the autoclaving process useless for sterilization. Dry heat sterilization is the appropriate method for these items.

Items Sensitive to Moisture

Certain materials are degraded by moisture. Paper, for example, will become brittle and unusable after being subjected to high-pressure steam. Sensitive electronics or certain medical implants also fall into this category.

Sealed Containers

Placing a completely sealed container in an autoclave is a recipe for an explosion. As the liquid inside heats up, pressure builds dramatically with no means of escape, turning the container into a projectile. All containers must be appropriately vented.

Radioactive or Toxic Contaminants

An autoclave sterilizes—it does not neutralize chemical or radiological hazards. Autoclaving these materials will simply create aerosolized, radioactive, or toxic steam, contaminating the autoclave and posing a severe risk.

Making the Right Choice for Your Goal

Selecting the correct sterilization method is critical for both safety and preserving the integrity of your materials. Always assess the item's composition before proceeding.

- If your item is a heat-sensitive plastic or liquid: Consider low-temperature sterilization methods like ethylene oxide (EtO) gas or filtration.

- If your item is an oil, powder, or another anhydrous substance: Use a dry heat oven, as it does not rely on steam penetration.

- If you are dealing with hazardous chemicals or radioactive materials: Do not attempt to sterilize them in this way; follow your institution's specific hazardous waste disposal protocols.

Ultimately, your goal is to achieve sterility without causing damage or creating a hazard, so always verify material compatibility first.

Summary Table:

| Material Type | Reason to Avoid Autoclaving |

|---|---|

| Heat-sensitive plastics (e.g., PVC, polystyrene) | Melts or warps at high temperatures |

| Flammable or corrosive chemicals | Risk of explosion, toxic fumes, or equipment damage |

| Oils, powders, anhydrous substances | Steam cannot penetrate, preventing sterilization |

| Sealed containers | Pressure buildup can cause explosions |

| Moisture-sensitive items (e.g., paper, electronics) | Degraded by direct steam contact |

| Radioactive or toxic materials | Creates hazardous aerosolized contaminants |

Ensure your lab's safety and efficiency with the right equipment from KINTEK.

Choosing the correct sterilization method is crucial for protecting your materials, your team, and your lab environment. If you're working with heat-sensitive, flammable, or moisture-sensitive items, autoclaving is not the answer.

KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. We can help you identify the best sterilization solution—whether it's a dry heat oven for powders, low-temperature methods for plastics, or guidance on hazardous waste disposal.

Contact us today via our contact form to discuss your specific requirements. Let our experts provide you with reliable equipment and tailored advice to keep your lab running safely and effectively.

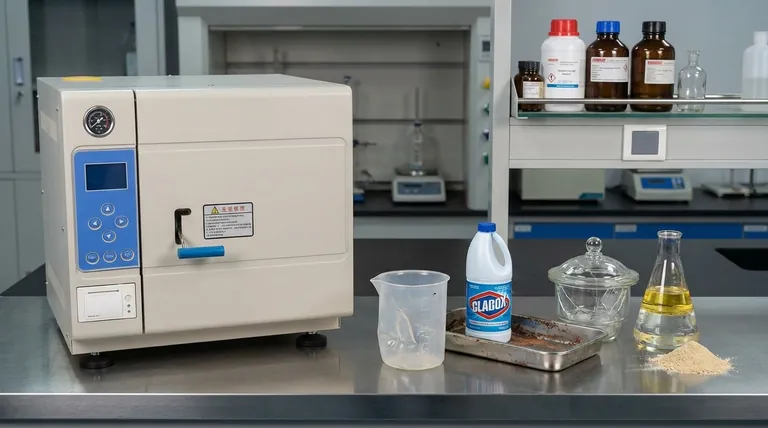

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- Is autoclave the same as sterilization? Unlocking the Key Differences for Lab Safety

- What is the 121 cycle of autoclave? A Guide to Guaranteed Sterilization

- What are the safety concerns when autoclaving? A Guide to Preventing Burns, Explosions, and Biohazards

- How does an autoclave sterilize instruments supplies and equipment? A Guide to High-Pressure Steam Sterilization

- What is the function of autoclave in tissue culture laboratory? Ensure Absolute Sterility for Successful Cell Growth