At its core, an autoclave is used anywhere that requires absolute sterility or the physical transformation of materials using high pressure and steam. You will find them in environments ranging from hospital operating rooms and dental offices to tattoo parlors and advanced manufacturing plants. They are the gold standard for eliminating all forms of microbial life—including bacteria, viruses, fungi, and resilient spores—from instruments and materials.

While often associated with medical sterilization, the fundamental purpose of an autoclave is broader. It is a device that uses pressurized, high-temperature steam to achieve a specific outcome, whether that is killing microorganisms or fundamentally changing a material's physical properties.

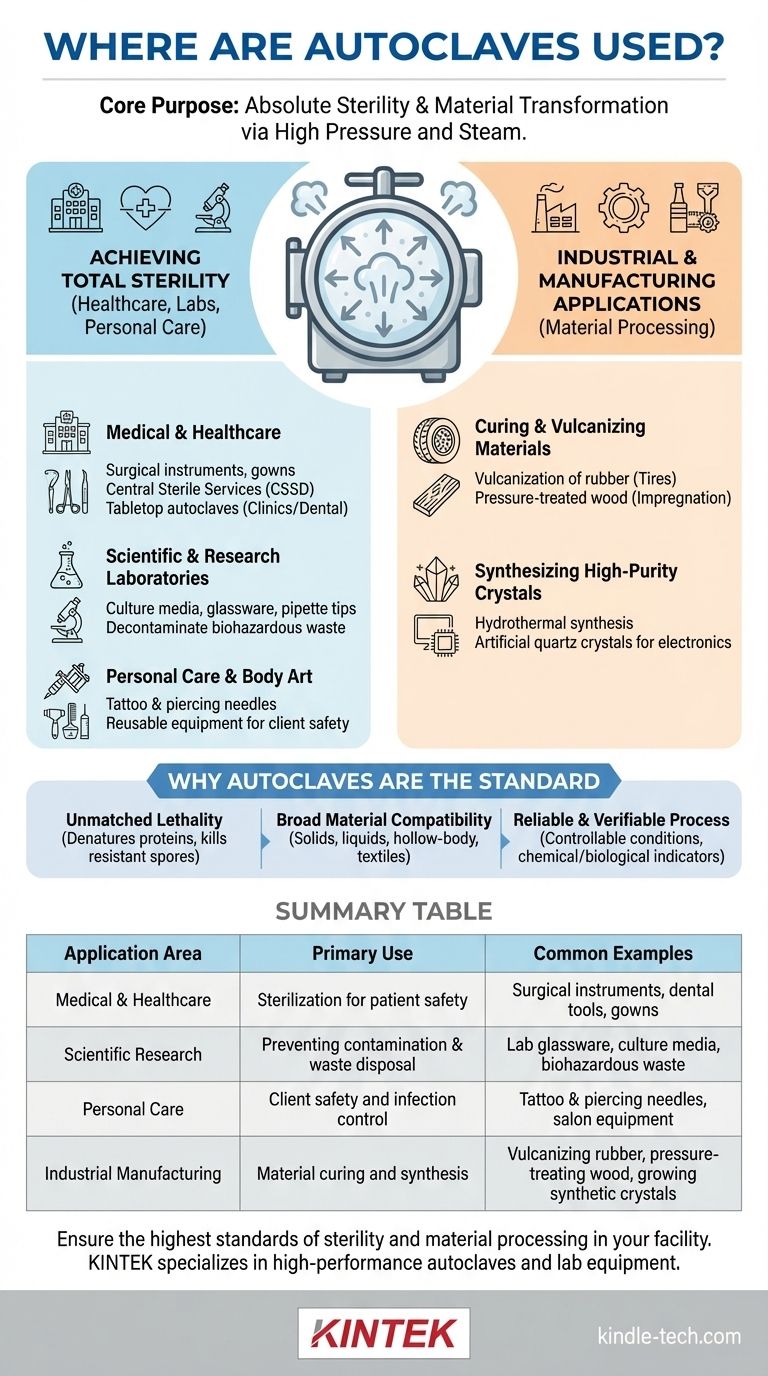

The Core Function: Achieving Total Sterility

The most common application of an autoclave is sterilization. In these settings, the goal is to create an environment free from any living microorganisms to prevent infection, contamination, or disease transmission.

Medical and Healthcare Environments

In healthcare, autoclaves are non-negotiable tools for patient safety. They are used to sterilize surgical instruments, gowns, and other materials that will come into contact with a patient.

Hospitals typically have a Central Sterile Services Department (CSSD) with large, industrial-scale autoclaves capable of processing vast quantities of equipment. Smaller clinics and dental practices use more compact tabletop autoclaves for the daily sterilization of their tools.

Scientific and Research Laboratories

Laboratories, particularly in microbiology and biotech, rely on autoclaves to maintain the integrity of their work. They are used to sterilize culture media, glassware, pipette tips, and other lab instruments to prevent the cross-contamination of experiments.

Furthermore, autoclaves are critical for safety, used to decontaminate biohazardous waste (like used petri dishes or test tubes) before it can be disposed of safely.

Personal Care and Body Art

To protect client health, autoclaves are standard equipment in reputable tattoo and piercing studios, as well as some beauty salons. They sterilize needles, grips, and other reusable equipment to prevent the transmission of blood-borne pathogens. This is crucial because simple detergents or boiling water are not sufficient to kill all resistant organisms.

Beyond Sterilization: Industrial and Manufacturing Applications

While sterilization is its most famous role, the underlying technology of high pressure and heat gives the autoclave powerful industrial capabilities that have nothing to do with killing microbes.

Curing and Vulcanizing Materials

In manufacturing, large industrial autoclaves are used to process and cure materials. The vulcanization of rubber for car tires, for instance, often takes place in an autoclave to enhance the rubber's strength and durability.

This same principle is applied to create pressure-treated wood, where the autoclave helps impregnating agents penetrate deep into the lumber, protecting it from rot and insects.

Synthesizing High-Purity Crystals

A highly specialized industrial use for autoclaves is in growing synthetic crystals. The high-temperature, high-pressure environment inside an autoclave is ideal for hydrothermal synthesis, the process used to create large, flawless artificial quartz crystals for the electronics industry.

Why Autoclaves are the Standard

An autoclave is chosen over other methods due to its unmatched effectiveness and versatility. Understanding why it's the standard reveals its true value.

Unmatched Lethality

Autoclaves use pressurized steam to reach temperatures (typically 121-134°C or 250-273°F) that are impossible to achieve with boiling water alone. This intense, penetrating heat denatures the essential proteins of all microbial life, including highly resistant bacterial spores that can survive lesser cleaning methods.

Broad Material Compatibility

Unlike some chemical or radiation-based sterilization methods, steam is compatible with a vast range of materials. Autoclaves can safely process solids, liquids (like saline solutions or culture media), hollow-body instruments, textiles, and various autoclavable plastics and glassware.

Reliable and Verifiable Process

The sterilization process within an autoclave is highly controllable and verifiable. Operators use chemical and biological indicators to confirm that the necessary conditions for sterility were met during each cycle, ensuring a reliable and auditable outcome.

Identifying the Autoclave's Role in Any Setting

By understanding its primary functions, you can quickly deduce an autoclave's purpose in any environment.

- If your focus is on a medical, dental, or personal care setting: The autoclave is there to ensure patient and client safety through the complete sterilization of reusable instruments.

- If your focus is on a scientific laboratory: The autoclave serves a dual purpose of preventing experimental contamination and safely decontaminating hazardous biological waste.

- If your focus is on an industrial or manufacturing plant: The autoclave is most likely a production tool used to alter the physical properties of materials like rubber, wood, or composites under intense heat and pressure.

Ultimately, the autoclave is a cornerstone technology, ensuring safety in healthcare and enabling innovation in modern manufacturing.

Summary Table:

| Application Area | Primary Use | Common Examples |

|---|---|---|

| Medical & Healthcare | Sterilization for patient safety | Surgical instruments, dental tools, hospital gowns |

| Scientific Research | Preventing contamination & waste disposal | Lab glassware, culture media, biohazardous waste |

| Personal Care | Client safety and infection control | Tattoo and piercing needles, salon equipment |

| Industrial Manufacturing | Material curing and synthesis | Vulcanizing rubber, pressure-treating wood, growing synthetic crystals |

Ensure the highest standards of sterility and material processing in your facility. KINTEK specializes in high-performance autoclaves and lab equipment, serving the precise needs of healthcare providers, research laboratories, and manufacturing plants. Our solutions deliver reliable, verifiable results for critical applications. Contact our experts today to find the perfect autoclave for your specific requirements!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What is the normal temperature of an autoclave? Achieve Sterile Confidence with Precise Control

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety