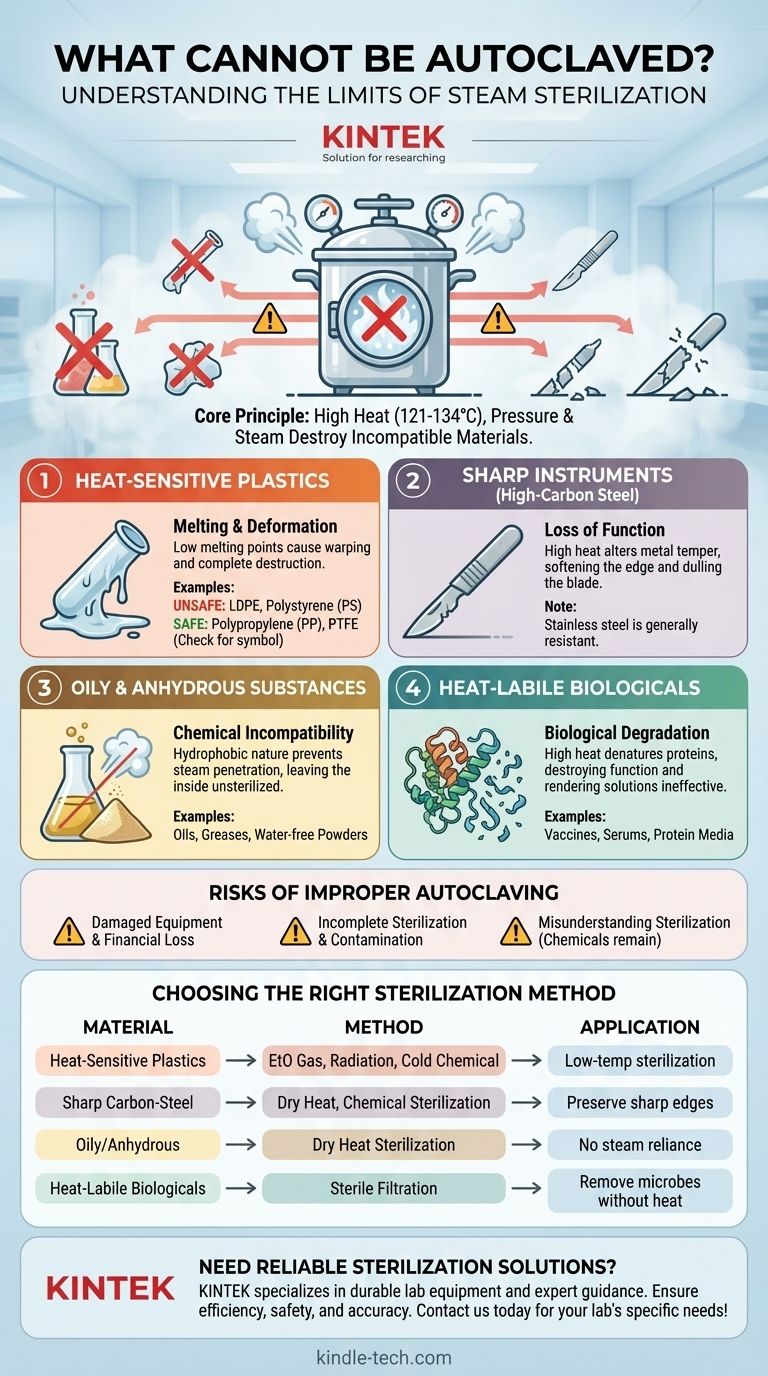

In short, any material that cannot withstand high heat, pressure, and steam is unsuitable for an autoclave. This includes most heat-sensitive plastics, certain sharp-edged metal instruments, oily or anhydrous (water-free) substances, and heat-labile biological solutions like vaccines. The intense conditions are designed to destroy microbial life but will equally damage or destroy materials not engineered to tolerate them.

Autoclaving relies on pressurized steam to sterilize, a process that is fundamentally incompatible with materials that melt, degrade, or are impervious to steam. The central question is not just "can it be sterilized?" but "can it survive the sterilization process intact and effective?"

The Core Principle: Why High-Heat Steam Fails Certain Materials

An autoclave works by exposing items to steam at temperatures typically around 121-134°C (250-273°F) under high pressure. This combination of heat and moisture is extremely effective at denaturing the proteins in microorganisms, rendering them sterile.

However, this same mechanism is the reason why certain materials cannot be autoclaved. The process attacks materials based on their physical and chemical properties.

Material Instability: Melting and Deformation

Many common plastics have a melting point below the operating temperature of an autoclave. Attempting to autoclave them results in melting, warping, and complete destruction.

While some plastics like polypropylene (PP) and polytetrafluoroethylene (PTFE) are designed to be autoclavable, materials like low-density polyethylene (LDPE) and polystyrene (PS) will not survive. Always check for the "autoclavable" symbol or manufacturer's specifications.

Loss of Function: The Dulling of Sharp Instruments

High-carbon steel is prized for its ability to hold an extremely sharp edge, making it ideal for scalpels and high-grade scissors.

However, the high heat of an autoclave can alter the temper of this metal. This process softens the steel, causing the fine cutting edge to lose its hardness and become dull, rendering the instrument useless for precision work. Stainless steel instruments are generally more resistant and suitable for autoclaving.

Chemical Incompatibility: Oils and Powders

Steam sterilization requires direct contact between the steam and every surface of the item. Oily or greasy substances are hydrophobic, meaning they repel water.

When you place an oily substance in an autoclave, the steam cannot penetrate it. It will simply heat the outside of the substance, leaving the inside unsterilized. The same principle applies to anhydrous powders, which steam cannot effectively permeate.

Biological Degradation: Heat-Labile Solutions

The goal of sterilizing solutions like vaccines, serums, or certain protein media is to remove microbial contaminants without destroying the active components.

The very heat that kills microbes will also denature the complex proteins in these biologicals. This process unfolds the proteins, destroying their function and rendering the solution ineffective.

Understanding the Risks of Improper Autoclaving

Attempting to autoclave an incompatible item is not just a matter of inconvenience; it poses significant risks to equipment, safety, and scientific validity.

Damaged or Destroyed Equipment

The most immediate consequence is financial loss. A melted batch of plasticware or a set of dulled surgical scissors must be replaced. In a worst-case scenario, melted plastic can damage the autoclave itself, leading to costly repairs.

Incomplete Sterilization Failure

This is the most critical risk. If you attempt to autoclave an oily liquid, you may assume it is sterile when it is not. Using this non-sterile material can lead to contamination, failed experiments, or in a clinical setting, a serious infection risk.

Misunderstanding the Scope of Sterilization

It is crucial to remember that an autoclave sterilizes—it kills living organisms. It does not remove chemical contamination. If an instrument is contaminated with a chemical residue, autoclaving will not eliminate that hazard.

Choosing the Right Sterilization Method

The correct method depends entirely on the material you need to sterilize.

- If your primary focus is heat-resistant glassware, liquids, or standard stainless steel instruments: The autoclave is your gold standard for effective and efficient sterilization.

- If your primary focus is sharp carbon-steel instruments or heat-sensitive plastics: You must use non-heat methods like ethylene oxide (EtO) gas, radiation, or cold liquid chemical sterilization.

- If your primary focus is oily substances or anhydrous powders: Dry heat sterilization is the appropriate thermal method, as it does not rely on steam penetration.

- If your primary focus is sensitive biologicals like vaccines or serums: Sterile filtration is the required method to remove microorganisms without damaging the product through heat.

Ultimately, selecting the correct sterilization method is essential for ensuring both material integrity and absolute sterility.

Summary Table:

| Material/Instrument Type | Why It Cannot Be Autoclaved | Alternative Sterilization Method |

|---|---|---|

| Heat-Sensitive Plastics (e.g., LDPE, Polystyrene) | Melts or deforms at high temperatures (121-134°C) | Ethylene Oxide (EtO) Gas, Radiation, Cold Chemical Sterilization |

| Sharp Carbon-Steel Instruments (e.g., Scalpels) | Heat alters metal temper, dulling the cutting edge | Dry Heat, Chemical Sterilization |

| Oily Substances or Anhydrous Powders | Steam cannot penetrate hydrophobic materials | Dry Heat Sterilization |

| Heat-Labile Biologicals (e.g., Vaccines, Serums) | High heat denatures proteins, destroying function | Sterile Filtration |

Need Reliable Sterilization Solutions for Your Lab?

Choosing the wrong sterilization method can lead to damaged equipment, contamination, and costly errors. At KINTEK, we specialize in providing durable lab equipment and expert guidance to help you select the right tools—whether you need autoclavable items or alternatives for sensitive materials. Our products ensure your lab maintains efficiency, safety, and accuracy.

Contact us today to discuss your lab’s specific needs and discover how KINTEK’s solutions can support your sterilization protocols!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory Horizontal Autoclave Steam Sterilizer Lab Microcomputer Sterilizer

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- How long does autoclave liquid cycle take? The Truth About Sterilization Time & Safety

- What are the four applications of autoclave? Essential Sterilization for Healthcare, Labs & Industry

- What other temperatures and times can be used to autoclave? Beyond 121°C for 15 Minutes

- What are the maintenance procedures for autoclave? Ensure Sterilization Safety and Reliability

- Why are high-pressure hydrothermal autoclaves essential for IrRu@Te synthesis? Achieve Peak Catalyst Stability

- What role does a high-pressure stainless steel autoclave play in synthesizing FOTS-TiO2? Mastering Material Morphology

- Why are autoclave parameters 121°C for 15 minutes? The Science of Sterilizing Bacterial Spores

- How does a Teflon-lined stainless steel autoclave facilitate the hydrothermal synthesis of Co(OH)F nanowire precursors?