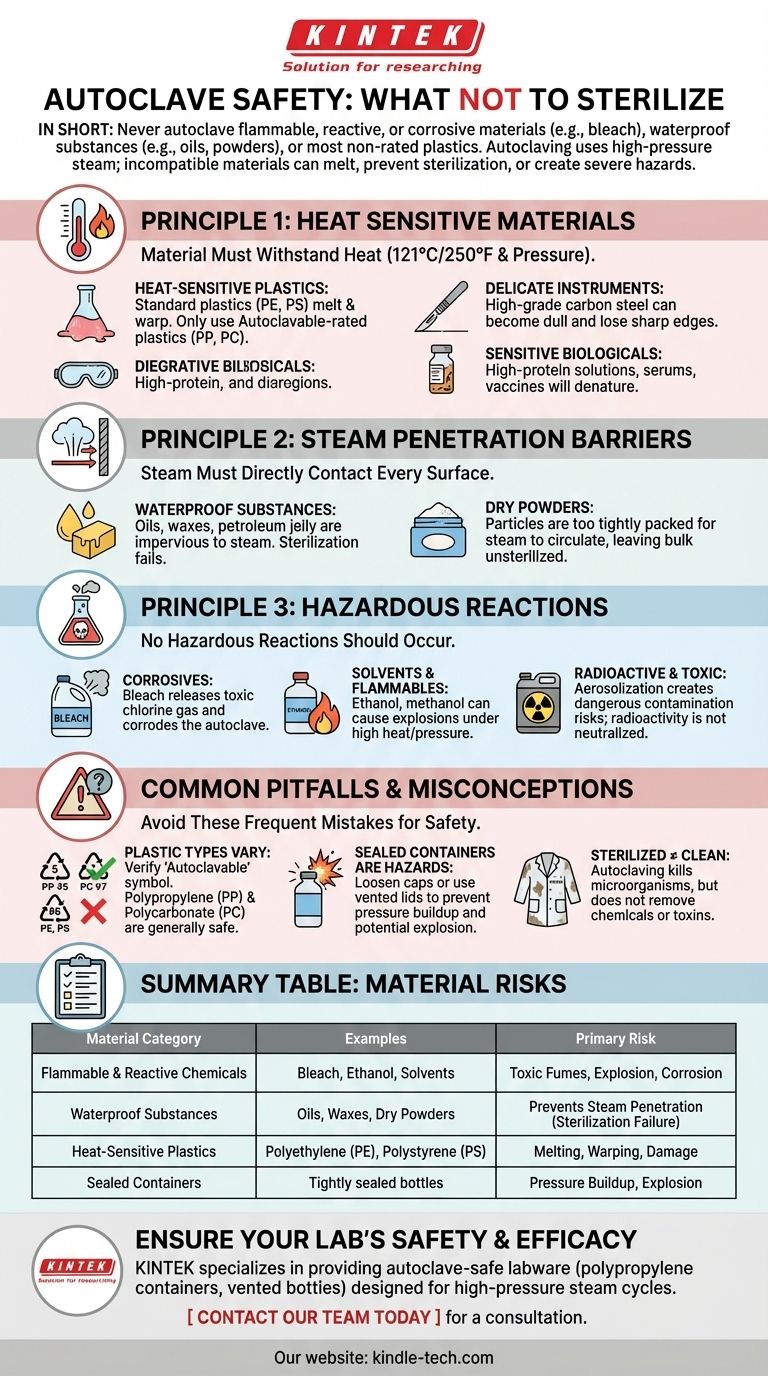

In short, you must never autoclave flammable, reactive, or corrosive materials like bleach, waterproof substances like oils and powders, or most non-rated plastics. An autoclave uses high-pressure steam to sterilize, and materials that are damaged by heat, prevent steam penetration, or create a chemical hazard are fundamentally incompatible with this process.

An autoclave is not a universal sterilizer. Its effectiveness is entirely dependent on high-pressure steam making direct contact with an object, meaning any material that is heat-sensitive, water-repellent, or chemically reactive is not only unsuitable but potentially dangerous to autoclave.

Why Certain Materials Cannot Be Autoclaved

An autoclave works by exposing items to steam at high temperatures (typically 121°C or 250°F) and high pressure. This combination effectively kills microorganisms. Any material that cannot withstand these conditions, or interferes with the process, is unsafe to include.

Principle 1: The Material Must Withstand Heat

Many common materials will melt, warp, or degrade under the intense heat and pressure of an autoclave cycle.

- Heat-Sensitive Plastics: Most standard plastics, like polyethylene (PE) or high-density polyethylene (HDPE), will melt. Only plastics specifically rated for autoclaving, such as polypropylene (PP) or polycarbonate (PC), should be used.

- Certain Instruments: High-grade carbon steel surgical instruments, such as scalpel blades, can become dull and lose their sharp edge when exposed to the high temperatures and moisture.

- Sensitive Biologicals: High-protein solutions, serums, and vaccines will denature and degrade, rendering them useless. The heat effectively "cooks" the active components.

Principle 2: Steam Must Be Able to Penetrate

The core of autoclave sterilization is direct steam contact. If steam cannot reach every surface of an object, sterilization will fail.

- Waterproof Substances: Oils, waxes (like paraffin), and petroleum jelly are impervious to steam. The steam cannot penetrate to kill microorganisms within the substance.

- Powders: Dry powders are also resistant to steam penetration. The particles are so tightly packed that steam cannot circulate effectively, leaving the bulk of the powder unsterilized.

Principle 3: No Hazardous Reactions Must Occur

Placing certain chemicals in an autoclave can create immediate and severe safety hazards, from toxic fumes to explosions.

- Corrosives: Household bleach (sodium hypochlorite) will break down and release toxic chlorine gas. It will also corrode the stainless steel chamber of the autoclave itself.

- Solvents and Flammables: Liquids like ethanol, methanol, or other flammable solvents can create a risk of explosion under the high-heat, high-pressure conditions.

- Radioactive or Toxic Materials: Autoclaving does not neutralize radioactivity or many chemical toxins. It can, however, aerosolize them, creating a dangerous contamination risk when the door is opened.

Common Pitfalls and Misconceptions

Understanding what to avoid is critical for both safety and effectiveness. Mistakes are common and can have serious consequences.

Not All Plastics Are Created Equal

The most frequent mistake is assuming any lab plastic can be autoclaved. Look for the "autoclavable" symbol or the plastic recycling code. Polypropylene (PP, #5) and Polycarbonate (PC, #7) are generally safe, while Polyethylene (PE) and Polystyrene (PS, #6) will melt.

Sealed Containers Are a Hazard

Never autoclave a completely sealed container. As the liquid inside heats up, it will expand and create immense pressure, turning the container into a potential bomb. Always loosen the caps on bottles or use vented lids.

"Sterilized" Doesn't Mean "Clean"

An autoclave kills microorganisms, but it does not remove chemicals or toxins. Do not attempt to "clean" a chemical spill by autoclaving the contaminated items. This will only bake on the chemical or, worse, vaporize it into the air.

Making the Right Choice for Your Goal

Always verify an item's compatibility before placing it in an autoclave. When in doubt, find an alternative method.

- If your primary focus is sterilizing lab glassware or media: Ensure all plastics are polypropylene (PP) and that bottle caps are loosened to allow for pressure changes.

- If your primary focus is disposing of biohazardous waste: Use only designated, vented autoclave bags and never add bleach or other chemicals to the bag.

- If your primary focus is sterilizing delicate items or solutions: Consider alternatives like filtration for heat-sensitive liquids or ethylene oxide (EtO) sterilization for heat-sensitive instruments.

Ultimately, understanding the principles of steam sterilization is the key to using an autoclave safely and effectively.

Summary Table:

| Material Category | Examples | Primary Risk |

|---|---|---|

| Flammable & Reactive Chemicals | Bleach, Ethanol, Solvents | Toxic Fumes, Explosion, Corrosion |

| Waterproof Substances | Oils, Waxes, Dry Powders | Prevents Steam Penetration (Sterilization Failure) |

| Heat-Sensitive Plastics | Polyethylene (PE), Polystyrene (PS) | Melting, Warping, Damage |

| Sealed Containers | Tightly sealed bottles, non-vented vessels | Pressure Buildup, Explosion |

Ensure your lab's safety and sterilization efficacy.

Choosing the right equipment and consumables is fundamental to safe autoclave operation. KINTEK specializes in providing autoclave-safe labware, including polypropylene containers and vented bottles, designed to withstand high-pressure steam sterilization cycles.

Our experts can help you select the right materials for your specific application, ensuring compliance and protecting your valuable equipment. Don't risk damage or hazardous incidents—contact our team today for a consultation on your laboratory's sterilization needs.

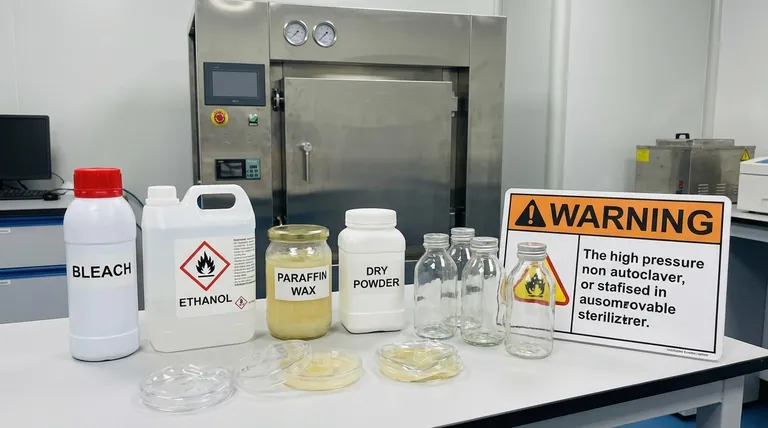

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What materials are used in sterilization? Match the Right Method to Your Lab Equipment

- How do you sterilize lab equipment without an autoclave? Discover Reliable Alternatives for Your Lab

- What are the guidelines for loading an autoclave? Ensure Sterilization Success & Safety

- Why is a high-pressure circulating autoclave necessary for PWR corrosion testing? Replicating Nuclear Environments

- What should not be autoclaved? A Guide to Avoiding Damage and Hazard

- Why are hydrothermal synthesis autoclaves used for mesoporous HA catalysts? Engineering Superior Catalytic Efficiency

- What factors may result in sterilization failure when using an autoclave? Prevent Failed Cycles with Expert Tips

- What is the importance of using a laboratory autoclave in ZSM-5 synthesis? Achieve Perfect Zeolite Crystallization