To avoid the inhalation of harmful chemical vapors, you must use a respirator equipped with the correct chemical cartridges. Standard dust masks, surgical masks, or N95 masks are designed for particles and offer no protection against gases and vapors. The key is using an air-purifying respirator (APR) with cartridges specifically rated for the chemical hazard you face.

The most critical takeaway is that "respirator" is not a one-size-fits-all term. Effective protection from chemical vapors depends entirely on selecting the right type of respirator and the correct cartridge for the specific chemical, and ensuring the mask forms a perfect seal on your face.

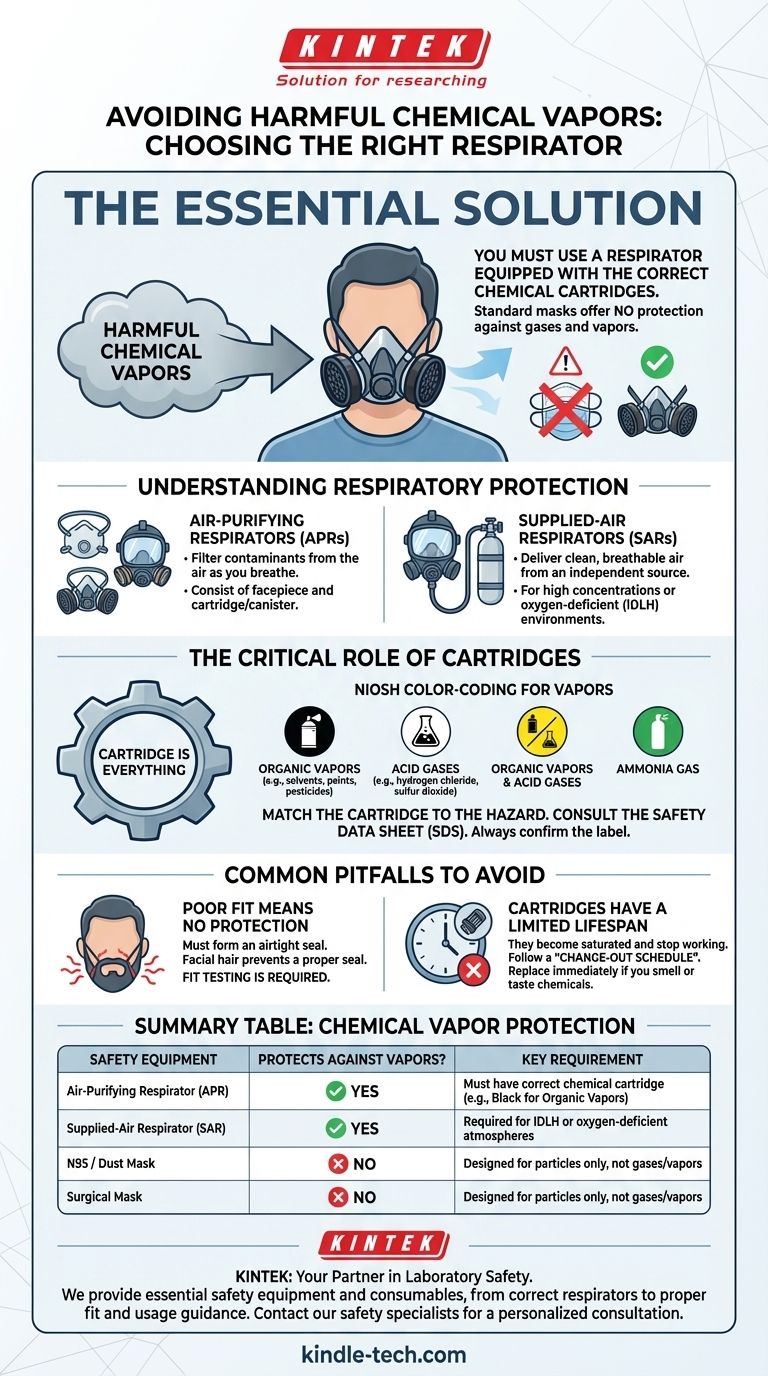

Understanding the Types of Respiratory Protection

To make an informed choice, you must first understand the fundamental difference between the major categories of safety equipment designed for breathing protection. They are not interchangeable.

Air-Purifying Respirators (APRs)

APRs are the most common type used for protection against vapors. They work by filtering contaminants from the air as you breathe.

These devices consist of a facepiece and a filtering element. The facepiece can be a half-mask (covering the nose and mouth) or a full-face mask (covering the eyes, nose, and mouth).

The most important component is the cartridge or canister. These contain materials, like activated carbon, that absorb or react with specific chemical vapors. You must match the cartridge to the hazard.

Supplied-Air Respirators (SARs)

Instead of filtering the surrounding air, SARs deliver clean, breathable air from an independent source like a compressor or a tank.

These are used in environments where the hazards are unknown, the vapor concentration is extremely high, or there isn't enough oxygen to support life (Immediately Dangerous to Life or Health - IDLH). This category includes Self-Contained Breathing Apparatus (SCBA), the equipment used by firefighters.

The Critical Role of Cartridges

For an APR to work against vapors, the cartridge is everything. A respirator with the wrong cartridge provides a false sense of security and zero effective protection.

Matching the Cartridge to the Hazard

You must identify the chemical vapor you need protection from. This information is found in the chemical's Safety Data Sheet (SDS), which specifies the required personal protective equipment (PPE).

NIOSH Color-Coding

The National Institute for Occupational Safety and Health (NIOSH) uses a color-coding system to help users identify cartridges. For chemical vapors, the most common is:

- Black: For Organic Vapors (e.g., solvents, paints, certain pesticides). This is the most widely used type for general vapor protection.

- White: For Acid Gases (e.g., hydrogen chloride, sulfur dioxide).

- Yellow: For Organic Vapors and Acid Gases.

- Green: For Ammonia Gas.

Always confirm the cartridge's written label, as colors are only a guide.

Common Pitfalls to Avoid

Simply wearing the right type of respirator is not enough. Several critical factors can render the equipment useless, exposing you to the very hazards you're trying to avoid.

A Poor Fit Means No Protection

A respirator must form a complete, airtight seal against your face. Any gaps around the nose, cheeks, or chin will allow contaminated air to leak in, bypassing the filter.

Facial hair, even light stubble, will prevent a proper seal. For this reason, occupational safety regulations require users to be clean-shaven and undergo a formal fit test to ensure their specific mask model fits them correctly.

Cartridges Have a Limited Lifespan

Chemical cartridges do not last forever. They become "full" or saturated with the contaminants they have absorbed and stop working.

You must follow the manufacturer's instructions or establish a "change-out schedule" based on the chemical concentration, humidity, and your breathing rate. If you can smell or taste the chemical while wearing the respirator, you have already been exposed and must leave the area immediately.

Making the Right Choice for Your Task

Use the specific hazard and work environment to guide your decision.

- If your primary focus is protection from common solvents, paints, or fuels: An air-purifying half-mask respirator with an Organic Vapor (OV) cartridge is typically the correct choice.

- If you are working with a specific acid, ammonia, or other non-organic vapor: You must consult the chemical's Safety Data Sheet (SDS) to identify the specific cartridge required.

- If you are working in a confined space or an area with unknown vapor types or concentrations: You must use a supplied-air respirator (SAR or SCBA), as an air-purifying respirator is not safe.

- If your only hazard is dust, airborne particles, or non-chemical mists: An N95 filtering facepiece may be sufficient, but remember it provides zero protection from chemical vapors.

Ultimately, your safety depends on a systematic approach that starts with identifying the hazard, not just grabbing the nearest mask.

Summary Table:

| Safety Equipment | Protects Against Chemical Vapors? | Key Requirement |

|---|---|---|

| Air-Purifying Respirator (APR) | Yes | Must have correct chemical cartridge (e.g., Organic Vapor/Black) |

| Supplied-Air Respirator (SAR) | Yes | Required for IDLH or oxygen-deficient atmospheres |

| N95 / Dust Mask | No | Designed for particles only, not gases/vapors |

| Surgical Mask | No | Designed for particles only, not gases/vapors |

Protect your team and ensure compliance with the right safety equipment.

KINTEK specializes in providing laboratories with the essential safety equipment and consumables they need to operate safely and efficiently. From identifying the correct respirators and cartridges for your specific chemical hazards to ensuring proper fit and usage, our experts are here to help.

Contact our safety specialists today for a personalized consultation. We'll help you select the right PPE to protect against harmful vapors and create a safer lab environment.

Visual Guide

Related Products

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Vacuum Cold Trap Direct Cold Trap Chiller

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- High Purity Zinc Foil for Battery Lab Applications

People Also Ask

- How long does it take to solder? A guide to timing and technique for perfect joints

- What are the factors that can affect the rate of melting? Master the Science of Heat Transfer

- What is the difference between liquid state sintering and solid state sintering? Choose the Right Method for Your Materials

- What is the process of electron beam physical vapor deposition? Achieve High-Purity, High-Melting-Point Coatings

- What are the technical requirements for vacuum chambers in desalination? Boost Efficiency with Graphene Technology

- Can carbon nanotubes form naturally? Yes, and here's where nature makes them.

- What are 2 examples of deposition in chemistry? From Frost to Soot Explained

- Are sintered metal parts stronger than other methods? A Guide to Powder Metallurgy Performance