The standard autoclave temperature of 121°C is not arbitrary; it is the specific temperature, achieved under pressure, required to reliably destroy the most heat-resistant microorganisms known: bacterial endospores. This benchmark ensures that when an item is autoclaved correctly at 121°C for a minimum of 15 minutes, it achieves a state of true sterility, which is impossible with simple boiling water.

The core principle is that sterility demands the elimination of all life, including the toughest bacterial spores. The 121°C standard was established because it is the scientifically validated temperature at which saturated steam can penetrate and destroy these spores by irreversibly coagulating their essential proteins.

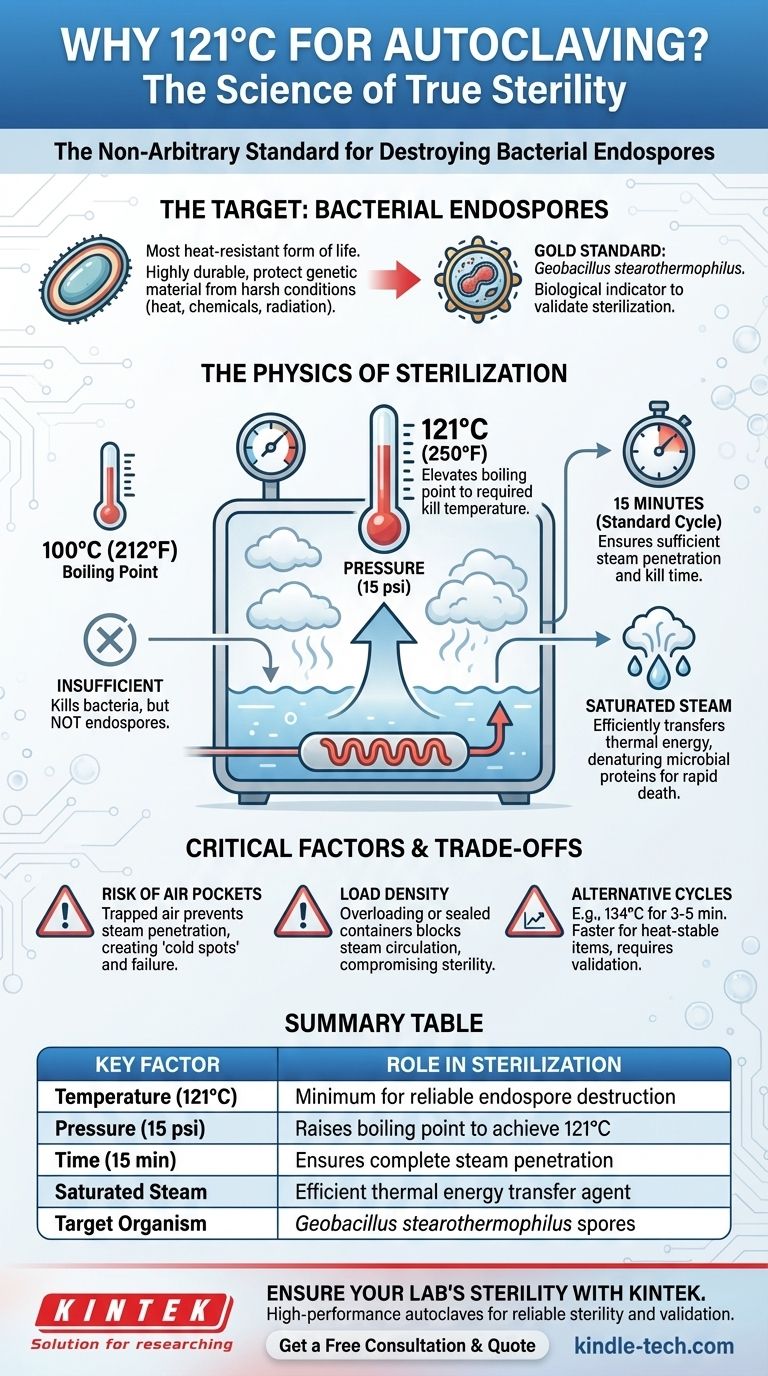

The Target: Why Spores Dictate the Standard

To understand the 121°C benchmark, you must first understand the enemy of sterilization. The goal is not merely to disinfect but to achieve complete sterility, a state with a statistically zero probability of a microorganism surviving.

The Problem of Bacterial Endospores

Most bacteria are relatively easy to kill with heat. However, some types of bacteria, like those from the Bacillus and Clostridium genera, can form endospores when faced with harsh conditions.

These spores are dormant, highly durable structures that protect the bacterium's genetic material. They are exceptionally resistant to heat, radiation, chemicals, and desiccation, making them the ultimate challenge for any sterilization process.

The Gold Standard: Geobacillus stearothermophilus

Scientists have identified the non-pathogenic spore-former Geobacillus stearothermophilus as one of the most heat-resistant organisms relevant to sterilization.

This organism's spores are used as the biological indicator to validate autoclave performance. If your process can kill these spores, it is certified to kill all other less-resistant microbes, ensuring a high Sterility Assurance Level (SAL). The conditions required to do this are 121°C for a sustained period.

The Physics of Sterilization: Heat, Pressure, and Time

Achieving 121°C requires more than just a heating element. It involves a precise interplay of physical principles that makes the autoclave so effective.

Why 100°C Isn't Enough

At standard atmospheric pressure, water boils at 100°C (212°F). While this temperature can kill most vegetative bacteria, it is insufficient to destroy bacterial endospores in a reasonable timeframe. Simply boiling an object does not sterilize it.

The Role of Pressure

To raise the temperature of steam above 100°C, you must increase the pressure. An autoclave is essentially a sophisticated pressure chamber.

By increasing the pressure inside the chamber to approximately 15 pounds per square inch (psi) or 103 kPa above atmospheric pressure, the boiling point of water is elevated to 121°C (250°F).

The Power of Saturated Steam

The true sterilization agent is saturated steam, not just hot air. Moist heat is far more effective at killing microorganisms than dry heat.

Steam efficiently transfers thermal energy to the items in the autoclave. This moisture then penetrates microbial cells and denatures and coagulates their essential proteins and enzymes, leading to rapid and irreversible death.

The Time Component

Temperature and time are inversely related. The standard cycle of 121°C for 15 minutes is a validated baseline. This duration ensures that the steam has enough time to penetrate the entire load and provide a sufficient "kill time" for all spores present.

Understanding the Trade-offs and Critical Factors

Simply setting the autoclave to 121°C does not guarantee sterility. Several factors can compromise the process, which is why understanding the principles is critical for proper operation.

The Risk of Air Pockets

The most common cause of autoclave failure is trapped air. If air is not properly evacuated from the chamber, it creates "cold spots" where steam cannot reach. Air acts as an insulator, preventing the load from reaching the target temperature of 121°C, even if the autoclave's sensors read correctly.

Load Density and Configuration

Steam must be able to circulate freely and contact every surface of the items being sterilized. Overloading the autoclave or using sealed containers prevents steam penetration, rendering the process ineffective for the items in the center or inside.

Temperature vs. Time

While 121°C at 15 minutes is the classic standard, other cycles exist. For instance, many medical facilities use a cycle of 134°C for 3-5 minutes. This higher temperature allows for a much shorter cycle time, increasing throughput for heat-stable instruments. The principle remains the same: ensuring sufficient thermal energy is delivered to kill the most resistant spores.

How to Apply This to Your Project

To apply this understanding, consider the goal of your specific autoclave cycle and the nature of the materials involved.

- If your primary focus is routine lab media or glassware: The 121°C for 15-20 minutes cycle is your reliable workhorse, as it is effective and less harsh on materials than higher-temperature cycles.

- If your primary focus is high-throughput medical instruments: A 134°C cycle may be more appropriate for efficiency, provided the instruments are validated to withstand the higher temperature without damage.

- If your primary focus is validating any sterilization process: Always use biological indicators containing G. stearothermophilus spores to confirm a successful kill, rather than relying solely on the machine's temperature and pressure readouts.

Understanding the science behind 121°C transforms autoclaving from a routine task into a precise and controllable method for guaranteeing sterility.

Summary Table:

| Key Factor | Role in Sterilization |

|---|---|

| Temperature (121°C) | Minimum temperature required to reliably destroy bacterial endospores |

| Pressure (15 psi) | Raises the boiling point of water to achieve 121°C |

| Time (15 min) | Ensures sufficient steam penetration and kill time for all spores |

| Saturated Steam | Transfers thermal energy efficiently to denature microbial proteins |

| Target Organism | Geobacillus stearothermophilus spores (biological indicator) |

Ensure Your Lab's Sterility with KINTEK

Understanding the science behind autoclaving is just the first step. Proper equipment and validation are crucial for achieving true sterility in your laboratory workflows.

KINTEK specializes in high-performance autoclaves and laboratory sterilization equipment designed to meet the rigorous demands of research, healthcare, and industrial applications. Our solutions help you:

- Achieve reliable sterility with precise temperature and pressure control

- Validate your processes with equipment compatible with biological indicators

- Optimize throughput with cycles tailored to your specific materials and volume needs

- Prevent costly errors by eliminating air pockets and ensuring proper steam penetration

Don't leave your sterilization to chance. Contact our experts today to find the perfect autoclave solution for your laboratory's unique requirements.

Get a Free Consultation & Quote

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What are the advantages of autoclaving in hospitals? Achieve Unmatched Sterilization for Patient Safety

- How does a laboratory autoclave ensure the success of long-cycle continuous fermentation processes? Secure Pure Strains

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- Why is an autoclave required for treating biomass hydrolysate? Ensure Sterile Fermentation for High Yields

- What are the requirements for autoclave sterilization? Achieve True Sterility with the Right Parameters

- How much time is required for autoclave sterilization of instruments? Understand the Full Cycle for Safety

- What are the specifications of a laboratory autoclave? A Guide to Key Features for Safe Sterilization

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment