In short, autoclaves are set to 121°C because this is the scientifically validated temperature required to destroy the most heat-resistant life forms on Earth: bacterial endospores. This temperature is not achievable with boiling water at normal atmospheric pressure. It requires the use of pressurized steam, which is uniquely effective at transferring lethal heat to ensure true sterilization.

The 121°C standard is not arbitrary; it is the cornerstone of sterilization. It represents the crucial balance point where, under pressure, steam has enough energy to guarantee the destruction of even the most resilient microorganisms without unnecessarily damaging the items being sterilized.

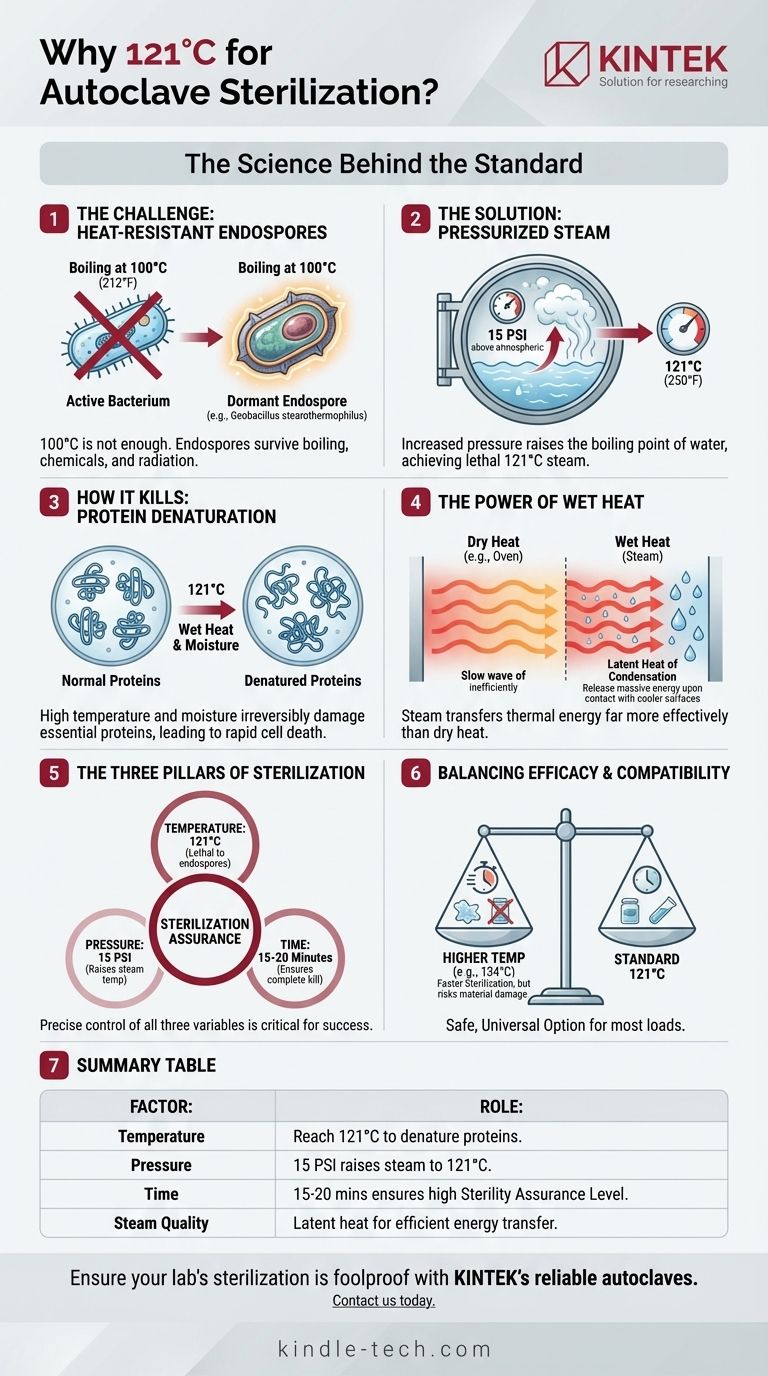

The Fundamental Challenge: Killing Everything

To understand the 121°C standard, you must first understand the primary target of sterilization. The goal isn't just to kill common, active bacteria; it's to eliminate every single living thing.

Beyond Simple Boiling: Why 100°C Isn't Enough

Boiling water at 100°C (212°F) is a good disinfectant, capable of killing most vegetative bacteria and viruses. However, it is not a reliable sterilant.

Many types of bacteria can form a dormant, armor-plated version of themselves called an endospore. These spores are not metabolically active and can survive boiling, radiation, and chemical attack.

The True Target: Bacterial Endospores

Endospores, particularly those from bacteria like Geobacillus stearothermophilus, are the gold standard for sterilization validation. They are exceptionally resistant to heat.

To ensure something is sterile, you must prove that you can kill these highly resistant spores. The conditions that kill them will reliably kill any less-resistant microbe. Scientific studies determined that sustained exposure to 121°C is the key to achieving this.

The Physics of Pressurized Steam

You cannot get liquid water hotter than 100°C at sea-level pressure; it simply turns into steam. To increase the temperature of steam, you must increase the pressure.

An autoclave is essentially a pressure cooker. By increasing the pressure inside the chamber to approximately 15 pounds per square inch (PSI) above atmospheric pressure, the boiling point of water is raised to 121°C (250°F).

How 121°C Achieves Sterilization

Reaching the right temperature is only half the battle. The method of heat delivery is what makes an autoclave so effective.

The Power of "Wet Heat"

Pressurized steam, or "wet heat," is far more effective at transferring thermal energy than "dry heat" (like in an oven). The moisture in the steam rapidly conducts heat into and through materials.

This process, known as latent heat of condensation, releases a massive amount of energy when steam condenses on a cooler surface. This is why a steam burn at 100°C is far more severe than a dry air burn at the same temperature.

The Mechanism of Killing: Protein Denaturation

The combination of high temperature and moisture is lethal to microorganisms. It works by denaturing and coagulating the essential proteins and enzymes within the cells.

Think of it like cooking an egg. The heat and moisture irreversibly change the structure of the egg white's proteins. In a microbial cell, this damage is catastrophic and leads to rapid death.

The Importance of Time

Temperature alone isn't enough. The items must be held at 121°C for a sufficient duration. The standard is typically 15-20 minutes for most loads.

This duration is calculated to provide a high Sterility Assurance Level (SAL). It ensures that even with a heavy bioburden, the probability of a single microbe surviving is infinitesimally small (often less than one in a million).

Understanding the Trade-offs

While 121°C is the classic standard, it's part of a balance between efficacy, speed, and material compatibility.

Why Not Go Higher?

Higher temperatures can achieve sterilization faster. For instance, many autoclaves also have a 134°C cycle, which can sterilize items in as little as 3-4 minutes.

However, this increased temperature and pressure can damage sensitive materials. Delicate plastics, certain liquids and growth media, and complex instruments may be degraded or destroyed at 134°C. The 121°C cycle is often a safer, more universal option.

The Critical Role of Air Removal

The greatest enemy of steam sterilization is trapped air. Air pockets act as an insulator, preventing steam from making direct contact with surfaces. This creates "cold spots" that will not reach 121°C, leading to sterilization failure.

This is why proper loading of an autoclave is critical. Items must be arranged to allow for steam circulation and air removal. Modern autoclaves often use vacuum pulses to actively remove air before the cycle begins.

The Three Pillars of Sterilization

Successful autoclaving depends on the precise control of three interconnected variables: Temperature, Pressure, and Time.

A failure to meet any one of these parameters will compromise the sterility of the entire load. Monitoring all three is essential for validating a cycle.

Making the Right Choice for Your Goal

Understanding the science behind the 121°C standard allows you to make more informed decisions in your work.

- If your primary focus is sterilizing robust items like glassware or surgical steel: The standard 121°C for 15-20 minutes is your reliable workhorse, but a 134°C cycle can significantly improve your workflow efficiency if your materials can tolerate it.

- If your primary focus is sterilizing liquids, media, or plastics: Stick to the 121°C standard to prevent degradation, and consider slightly longer cycle times for large liquid volumes to ensure the core reaches the target temperature.

- If your primary focus is process validation and quality assurance: Use biological indicators containing Geobacillus stearothermophilus spores to prove your autoclave is reaching the lethal conditions of 121°C for the required time throughout the entire load.

Mastering the autoclave means recognizing that 121°C isn't just a number, but a precise tool designed to conquer the toughest challenge in microbiology.

Summary Table:

| Key Factor | Role in Sterilization at 121°C |

|---|---|

| Temperature | Must reach 121°C to denature proteins in heat-resistant bacterial endospores. |

| Pressure | 15 PSI above atmospheric pressure raises steam temperature from 100°C to 121°C. |

| Time | 15-20 minutes exposure ensures a Sterility Assurance Level (SAL) of <1 in a million. |

| Steam Quality | Latent heat of condensation transfers energy efficiently for rapid microbial kill. |

Ensure your lab's sterilization is foolproof with KINTEK's reliable autoclaves. Whether you're processing glassware, sensitive media, or surgical instruments, our equipment delivers precise temperature, pressure, and time control to destroy even the most resistant bacterial endospores. Contact us today to find the perfect autoclave solution for your laboratory's unique needs.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What is the normal temperature of an autoclave? Achieve Sterile Confidence with Precise Control

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing