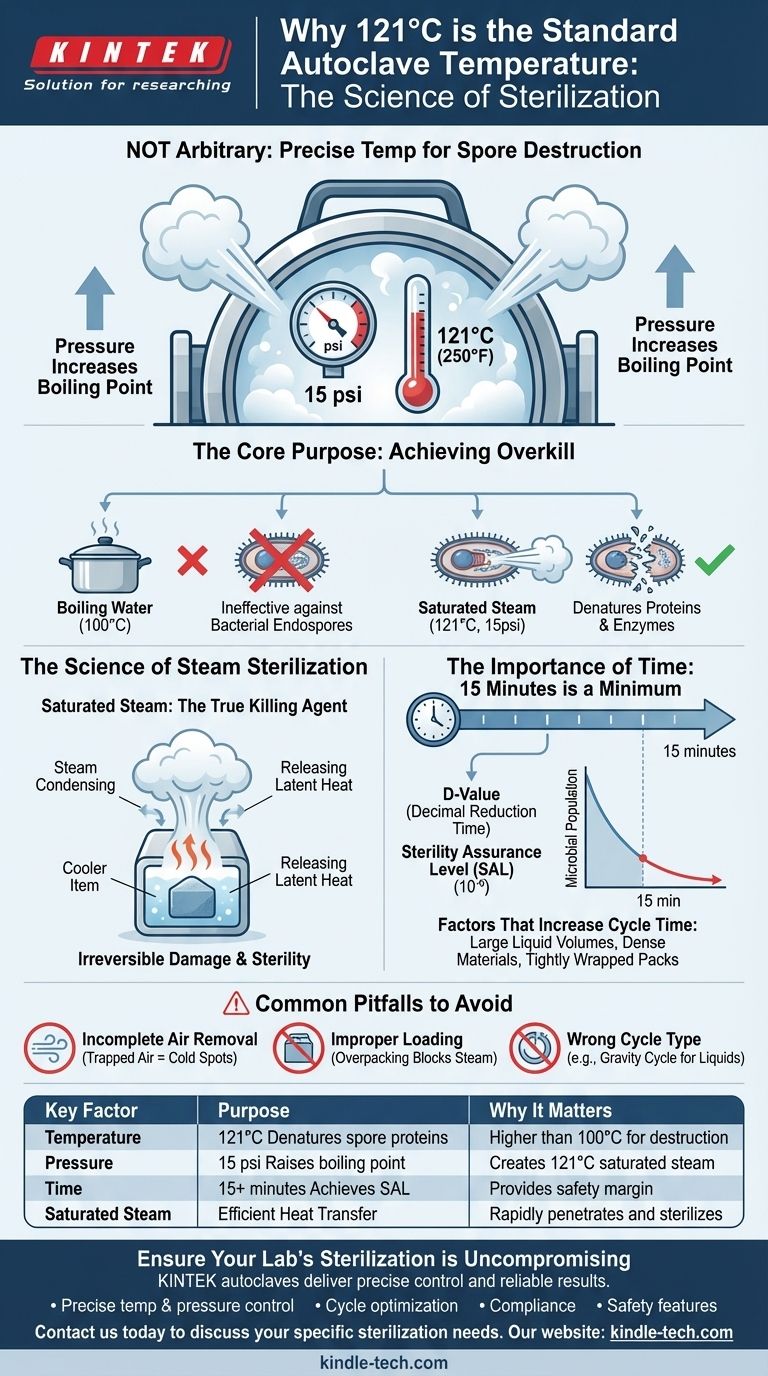

The standard 121°C temperature for autoclaving is not arbitrary. It is the precise temperature required to reliably destroy the most heat-resistant life forms known—bacterial endospores—using pressurized, saturated steam. This process, held for a minimum of 15 minutes, ensures true sterilization by targeting organisms that can easily survive boiling water at 100°C.

The core purpose of autoclaving is to achieve "overkill" by destroying highly resistant bacterial spores. 121°C is the critical temperature where pressurized steam carries enough thermal energy to rapidly penetrate and denature the essential proteins within these spores, guaranteeing complete sterility.

The Science of Steam Sterilization

To understand the importance of 121°C, we must first understand why simple boiling is not enough and how an autoclave overcomes this limitation.

Why Not Just Boil Water at 100°C?

Boiling water is a method of disinfection, not sterilization. It effectively kills most vegetative bacteria and viruses.

However, it is ineffective against bacterial endospores. These are dormant, highly protected structures produced by bacteria like Geobacillus and Bacillus that can withstand extreme environmental stress, including boiling temperatures.

The Critical Role of Pressure

The key to reaching higher temperatures is pressure. According to the laws of physics, the boiling point of water increases as pressure increases.

An autoclave is essentially a sophisticated pressure chamber. By increasing the internal pressure to approximately 15 psi (pounds per square inch) or 1 bar above atmospheric pressure, it raises the boiling point of water from 100°C (212°F) to 121°C (250°F).

Saturated Steam: The True Killing Agent

The sterilization process does not rely on hot water but on saturated steam. This "wet heat" is a far more efficient method of thermal energy transfer than "dry heat" (like in an oven).

When this 121°C steam makes contact with the cooler items inside the autoclave, it immediately condenses back into water. This condensation releases a massive amount of latent heat directly onto the surface of the items.

This intense, rapid heat transfer is what denatures the essential proteins and enzymes within the bacterial spores, causing irreversible damage and ensuring they are killed.

The Importance of Time: 15 Minutes is a Minimum

Reaching 121°C is only half the equation. Holding that temperature for a sufficient duration is what guarantees a complete kill.

The Concept of D-Value

In microbiology, sterilization efficacy is measured by the D-value (Decimal Reduction Time). This is the time required at a specific temperature to kill 90% of a microbial population.

The target organism for validating autoclaves is often Geobacillus stearothermophilus, as its spores have an exceptionally high resistance to heat.

Achieving a "Sterility Assurance Level"

The goal of sterilization is to achieve a Sterility Assurance Level (SAL), typically a 1 in 1,000,000 (10⁻⁶) probability of a single viable microorganism surviving.

The standard 15-minute cycle at 121°C is calculated to provide far more than the required number of log reductions for a typical bioburden. This provides a significant safety margin, often referred to as "overkill."

Factors That Increase Cycle Time

The 15-minute rule applies after the entire load has reached 121°C. The total cycle time is often much longer.

Factors like large liquid volumes, dense materials, or tightly wrapped instrument packs require longer cycles. This ensures that steam penetrates fully and the coldest part of the load is held at the target temperature for the entire 15-minute duration.

Common Pitfalls to Avoid

Achieving 121°C for 15 minutes is meaningless if the process is set up incorrectly.

Incomplete Air Removal

Trapped air is the enemy of sterilization. Air pockets create "cold spots" that prevent steam from making direct contact with surfaces, leading to sterilization failure. Proper loading and, for some materials, pre-vacuum cycles are essential to remove all air.

Improper Loading

Overpacking an autoclave is a common mistake. If items are packed too tightly, it blocks steam circulation and creates barriers to heat penetration, rendering the cycle ineffective.

Using the Wrong Cycle Type

Autoclaves have different cycles for different loads. Using a "gravity" or "fast exhaust" cycle for liquids (like media) will cause them to boil over violently. A dedicated "liquid cycle" with a slow, controlled pressure release is mandatory for these applications.

Matching the Cycle to Your Goal

The "121°C for 15 minutes" rule is a baseline, not a universal command. Your specific load dictates the correct approach.

- If your primary focus is hard goods (glassware, unwrapped metal tools): A standard gravity cycle at 121°C for 15-20 minutes is effective, assuming items are loaded to allow full steam circulation.

- If your primary focus is liquids (media, buffers): You must use a liquid cycle with slow exhaust, and the cycle time must be increased based on the volume to ensure the liquid core reaches 121°C.

- If your primary focus is porous loads (wrapped instruments, gowns, filters): These require a pre-vacuum cycle to remove trapped air and may need longer hold times (e.g., 30 minutes) to ensure complete steam penetration.

Understanding that 121°C is scientifically chosen to defeat the toughest microbial spores transforms autoclaving from a routine task into a precise, reliable scientific process.

Summary Table:

| Key Factor | Purpose | Why It Matters |

|---|---|---|

| Temperature: 121°C | Denatures proteins in bacterial spores | Higher than boiling point (100°C), ensuring spore destruction |

| Pressure: 15 psi | Raises water's boiling point | Enables creation of 121°C saturated steam |

| Time: 15+ minutes | Achieves sterility assurance level (SAL) | Provides safety margin for complete microbial kill |

| Saturated Steam | Efficient heat transfer via condensation | Rapidly penetrates and sterilizes all surfaces |

Ensure Your Lab's Sterilization is Uncompromising

Precise temperature control is just one part of effective sterilization. KINTEK specializes in laboratory autoclaves and sterilization equipment designed to deliver reliable, consistent results for research, healthcare, and industrial applications.

Our autoclaves feature:

- Precise temperature and pressure control

- Cycle optimization for different load types (liquids, porous materials, instruments)

- Compliance with sterility assurance standards

- Built-in safety features for complete peace of mind

Contact us today (#ContactForm) to discuss your specific sterilization needs. Let our experts help you select the perfect autoclave solution to protect your research integrity and ensure laboratory safety.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What are the functions of an autoclave and alumina liner in LBE experiments? Protect Your Research & Data Integrity.

- How does the autoclave sterilize materials? Unlock the Power of Pressurized Steam for Absolute Sterility

- What is the maximum temperature range for an autoclave? Achieve Guaranteed Sterilization

- Why is a PTFE-Lined High-Pressure Autoclave Needed for ZE41A Alloy Coatings? Ensure Purity and Chemical Inertness

- How long should equipment be autoclaved? Ensure Proper Sterilization Time and Conditions

- Can an autoclave reach temps as high as 121 degrees Celsius? The Definitive Guide to Steam Sterilization

- What is the role of autoclave in sterilization? Achieve Absolute Sterilization with High-Pressure Steam

- Why is an autoclave necessary for an Immobilized Cell Reactor (ICR)? Ensure Scientific Validation and Sterile Matrices