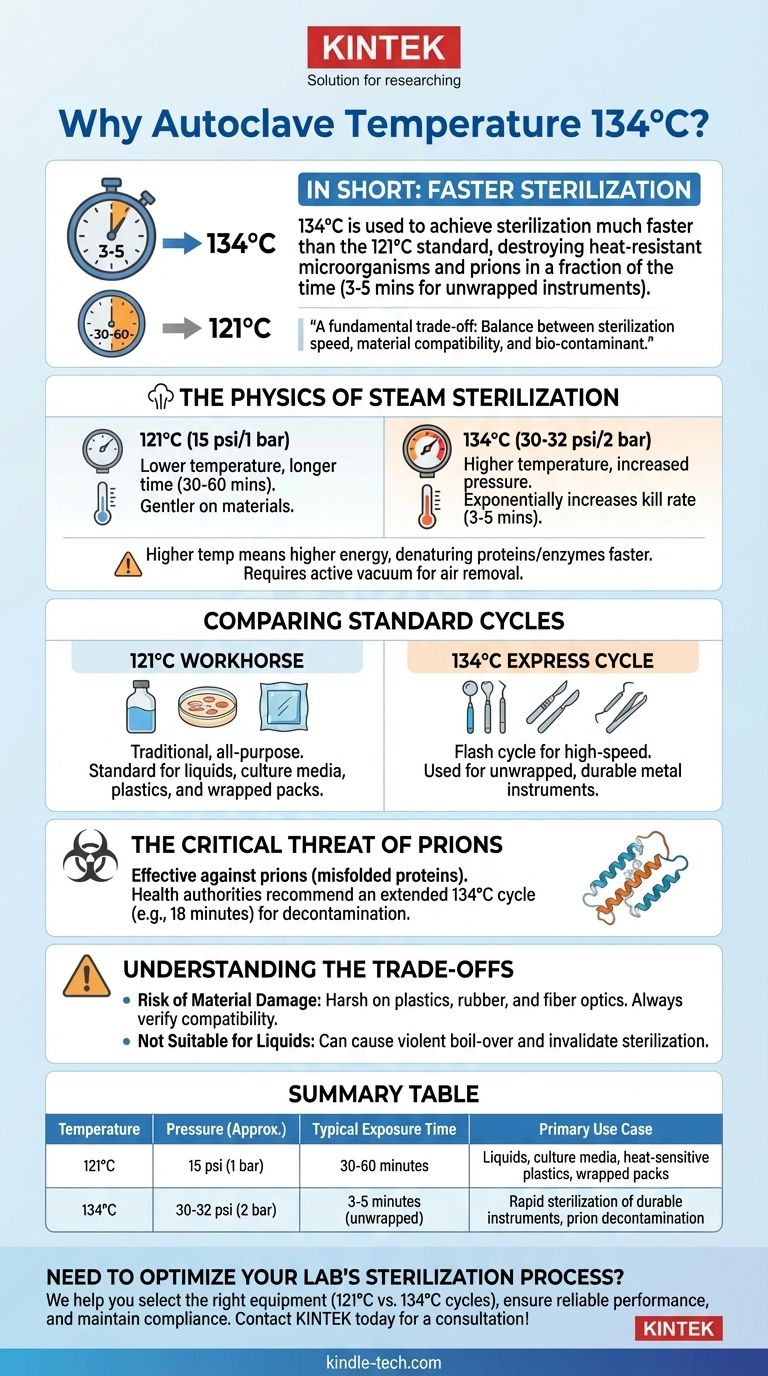

In short, an autoclave temperature of 134°C is used to achieve sterilization much faster than the traditional 121°C standard. This higher temperature imparts more energy, allowing it to destroy heat-resistant microorganisms and even prions in a fraction of the time, typically in just 3-5 minutes of exposure for unwrapped instruments. This makes it ideal for high-throughput environments like hospitals and dental clinics where rapid instrument turnaround is critical.

The choice between 121°C and 134°C is not about one being "better," but about a fundamental trade-off. It's a balance between sterilization speed, material compatibility, and the specific type of bio-contaminant you need to eliminate.

The Physics of Steam Sterilization

To understand why these different temperatures exist, you must first understand the core mechanism of an autoclave. It's not just about dry heat; it's about the power of pressurized, saturated steam.

The Role of Saturated Steam

Saturated steam is steam at the temperature at which it can condense back into water. When this steam makes contact with a cooler object (like a surgical instrument), it immediately condenses, releasing a massive amount of latent heat energy directly onto the surface. This combination of intense moisture and heat is exceptionally effective at denaturing the proteins and enzymes that all microorganisms rely on to live.

The Temperature-Pressure Relationship

In the sealed chamber of an autoclave, temperature and pressure are directly linked. To reach higher temperatures, you must increase the pressure.

- At 121°C, the required pressure is approximately 15 psi (1 bar) above atmospheric pressure.

- At 134°C, the pressure must be increased to roughly 30-32 psi (2 bar) above atmospheric pressure.

This increased pressure ensures the steam remains saturated at the higher temperature, maximizing its lethal efficiency.

Why Higher Temperature Means Faster Sterilization

The rate at which heat kills microorganisms increases exponentially with temperature. The intense thermal energy at 134°C destroys microbial structures far more rapidly than at 121°C. This allows the required exposure time for sterilization to drop dramatically, from over 30 minutes to as little as 3 minutes.

Comparing Standard Autoclave Cycles

The 121°C and 134°C cycles are designed for different purposes and different types of loads.

The 121°C Workhorse

This is the traditional, all-purpose cycle. Its lower temperature and longer time (typically 30-60 minutes depending on the load) are gentler on materials. It's the standard choice for sterilizing liquids, culture media, plastics, and large, densely wrapped packs where steam penetration requires more time.

The 134°C Express Cycle

Often called a "flash" cycle, this high-speed option is a cornerstone of modern clinical workflow. It is used primarily for unwrapped, durable metal instruments (like surgical or dental tools) that can withstand the higher temperature and need to be returned to service quickly.

The Critical Threat of Prions

A major reason for the adoption of the 134°C cycle is its effectiveness against prions. Prions are misfolded proteins that cause fatal neurodegenerative diseases (like Creutzfeldt-Jakob Disease) and are notoriously resistant to conventional sterilization methods. Health authorities worldwide recommend a 134°C cycle with an extended exposure time (e.g., 18 minutes) for the definitive decontamination of instruments suspected of prion contamination.

Understanding the Trade-offs

Using a higher temperature is not without its costs. It introduces limitations and risks that must be carefully managed.

Risk of Material Damage

The primary downside of the 134°C cycle is its harshness. Many plastics, rubber components, and complex fiber-optic devices that are perfectly safe at 121°C will be degraded or destroyed by the higher temperature. Always verify an instrument's compatibility before using a 134°C cycle.

Not Suitable for Liquids

Attempting to sterilize liquids at 134°C is extremely hazardous. The high temperature and the rapid pressure drop at the end of the cycle can cause liquids to boil over violently, creating a safety risk and invalidating the sterilization of any other items in the load.

Importance of Air Removal

At any temperature, trapped air is the enemy of steam sterilization because it creates cold spots that steam cannot penetrate. This issue is even more critical in the short, high-temperature 134°C cycles. For this reason, autoclaves running these cycles almost always incorporate an active vacuum system to ensure all air is removed from the chamber before steam is injected.

Selecting the Right Cycle for Your Needs

Choosing the correct cycle is a critical decision based on the items being sterilized and your operational requirements.

- If your primary focus is sterilizing liquids, media, or heat-sensitive plastics: The 121°C cycle is the safe and reliable standard.

- If your primary focus is the rapid turnaround of durable metal instruments: The 134°C cycle offers unparalleled speed and efficiency.

- If your primary focus is the guaranteed destruction of highly resistant prions: An extended 134°C cycle is the mandated protocol for maximum safety.

Ultimately, understanding the relationship between temperature, time, and material compatibility allows you to select the precise sterilization protocol for maximum safety and efficiency.

Summary Table:

| Temperature | Pressure (Approx.) | Typical Exposure Time | Primary Use Case |

|---|---|---|---|

| 121°C | 15 psi (1 bar) | 30-60 minutes | Liquids, culture media, heat-sensitive plastics, wrapped packs |

| 134°C | 30-32 psi (2 bar) | 3-5 minutes (unwrapped) | Rapid sterilization of durable instruments, prion decontamination |

Need to Optimize Your Lab's Sterilization Process?

Choosing the right autoclave cycle is critical for safety, efficiency, and material compatibility. KINTEK specializes in providing high-quality laboratory autoclaves and consumables designed to meet the rigorous demands of clinical and research environments.

We help you:

- Select the right equipment for your specific sterilization needs (121°C vs. 134°C cycles).

- Ensure reliable performance for high-throughput instrument processing.

- Maintain compliance with industry standards for prion decontamination.

Let our experts guide you to the perfect solution. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- How is an autoclave utilized in antimicrobial experiments? Ensure Precise Nanoparticle Research Integrity

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- How should solid materials in bags be prepared for decontamination? Master Steam Penetration for Safe Sterilization

- What is the necessity of using a steam autoclave for dental alloys? Ensure Pure Bacterial Adhesion Data

- Why is a 24-hour hydrothermal treatment in an autoclave necessary for BMO nanosheets? Unlock Superior Photocatalysis