Autoclaving is the most effective and reliable method of sterilization because it utilizes pressurized steam to achieve a combination of high temperature and moisture that is lethal to all forms of microbial life. This process efficiently transfers heat to denature the essential proteins of microorganisms, including the highly resistant spores that can survive simple boiling.

The unparalleled effectiveness of an autoclave lies not just in its high heat, but in its use of pressurized moist heat. This combination enables rapid heat penetration and leverages the destructive power of water molecules to irreversibly coagulate microbial proteins, a far more efficient killing mechanism than dry heat alone.

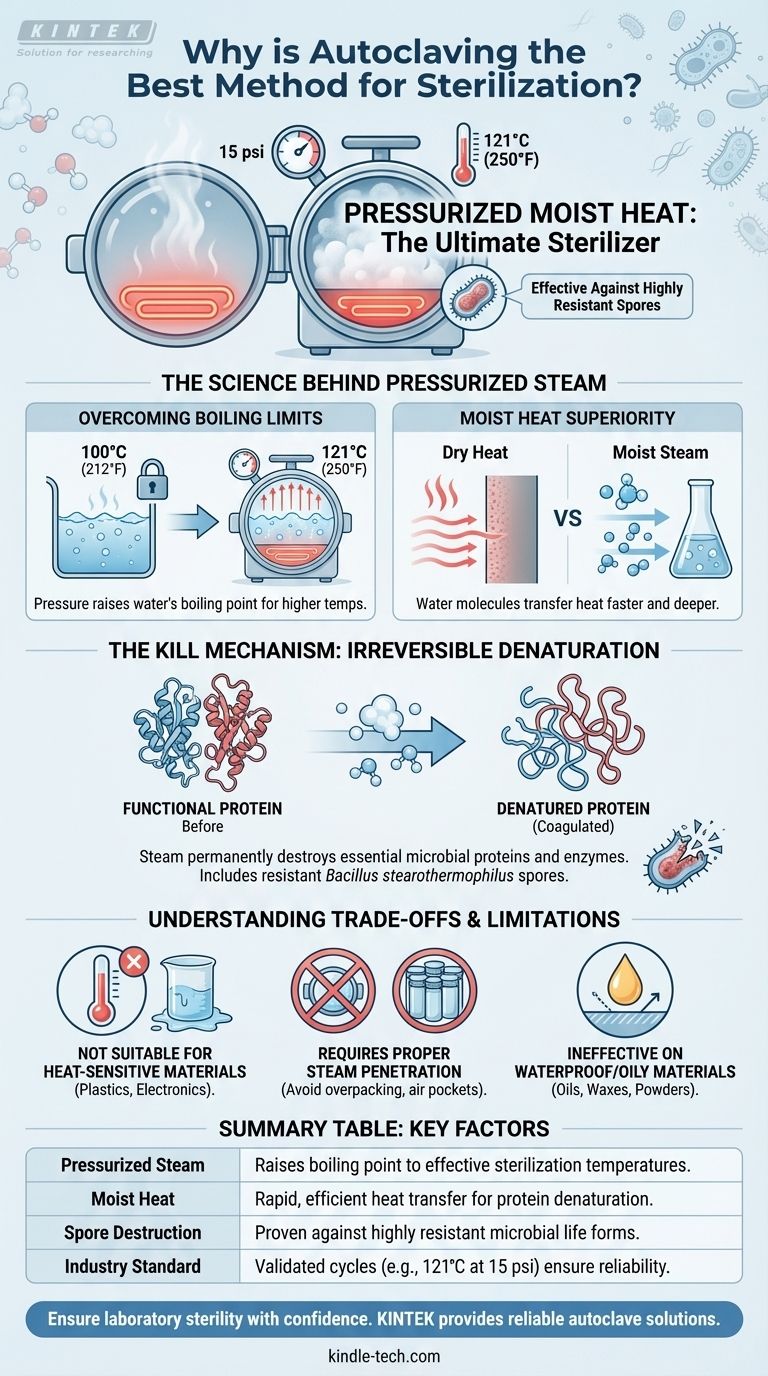

The Science Behind Pressurized Steam Sterilization

To understand why autoclaving is the gold standard, we must look at the physical principles that make it so powerful. It's a system designed to overcome the limitations of standard boiling water.

Overcoming the Limits of Boiling Water

At normal atmospheric pressure, water boils at 100°C (212°F). While this temperature is sufficient to kill many bacteria, it is not high enough to reliably destroy bacterial endospores, which are dormant, highly resistant structures produced by some bacteria to survive harsh conditions.

The Critical Role of Pressure

An autoclave is essentially a sophisticated pressure chamber. By increasing the internal pressure, it raises the boiling point of water, following the principles of gas laws. This allows the steam inside to reach much higher temperatures than are possible in an open environment.

The industry standard cycle for sterilization is typically set to 121°C (250°F) at a pressure of 15 psi (pounds per square inch) above atmospheric pressure.

Why Moist Heat is Superior

The moisture in the steam is the key to the autoclave's efficiency. Water is a much more effective conductor of heat than dry air. The moist steam rapidly transfers thermal energy to and through any items placed inside the chamber, ensuring rapid and even heat penetration.

The Kill Mechanism: Irreversible Denaturation

The true power of the autoclave lies in how it uses moist heat to destroy microorganisms at a cellular level. It's a process of complete and irreversible structural collapse.

Targeting Essential Proteins and Enzymes

All living cells, including bacteria and spores, depend on the precise three-dimensional structure of their proteins and enzymes to function. These molecules are the machinery of life.

Coagulation and Denaturation

The hot, moist steam causes these essential proteins and enzymes to coagulate and denature. This process irreversibly damages their structure, much like how cooking an egg white permanently changes its form and function. Once denatured, the microbial proteins can no longer perform their roles, leading to cell death.

Destroying Even the Toughest Spores

This method is so potent that it effectively destroys heat-resistant endospores. The effectiveness of an autoclave is validated using biological indicators, which are test vials containing spores of highly resistant bacteria like Bacillus stearothermophilus. If the autoclave cycle can kill these specific spores, it is considered successful in achieving true sterilization.

Understanding the Trade-offs and Limitations

While autoclaving is highly effective, its mechanism imposes certain limitations. Understanding these is crucial for proper application and safety.

Not Suitable for Heat-Sensitive Materials

The high temperatures and moisture will destroy or damage many materials. This includes most plastics, heat-labile chemicals, and sensitive electronic equipment.

The Importance of Steam Penetration

Sterilization only occurs where the pressurized steam makes direct contact. Items must be loaded correctly to allow for steam circulation. Overpacking the chamber or using improper containers can create air pockets or cold spots where microorganisms can survive.

Ineffective on Waterproof, Oily Materials

Autoclaving is not effective for sterilizing oils, waxes, or powders that are impervious to steam. The moist heat cannot penetrate these substances, leaving them unsterilized. For these materials, methods like dry heat sterilization are required.

Making the Right Choice for Your Goal

Applying the principles of autoclaving correctly ensures you achieve complete sterility for your specific application.

- If your primary focus is routine sterilization of glassware, media, or surgical instruments: Adhere strictly to a validated cycle, typically 121°C at 15 psi for at least 15-20 minutes, ensuring items are loaded to allow full steam penetration.

- If your primary focus is quality control and regulatory compliance: Regularly use biological indicators containing Bacillus stearothermophilus spores to prove your autoclave is functioning correctly and achieving a complete kill.

- If you are working with heat-sensitive or moisture-intolerant items: Recognize that autoclaving is the wrong method and explore appropriate alternatives like ethylene oxide gas, radiation, or filtration.

By understanding the principles of pressurized moist heat, you can confidently use the autoclave as a definitive tool for achieving absolute sterility.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| Pressurized Steam | Raises water's boiling point for higher, more effective temperatures (e.g., 121°C/250°F). |

| Moist Heat | Rapidly transfers heat and denatures microbial proteins more efficiently than dry heat. |

| Spore Destruction | Proven effective against the most resistant forms of microbial life, like Bacillus stearothermophilus. |

| Industry Standard | Validated cycle (121°C at 15 psi for 15-20 mins) ensures reliable, repeatable sterilization. |

Ensure your laboratory's sterility and compliance with confidence. KINTEK specializes in providing reliable autoclaves and lab sterilization equipment tailored to your needs. Whether you're processing glassware, media, or surgical instruments, our solutions deliver the guaranteed sterility your work demands. Contact our experts today to find the perfect autoclave for your laboratory.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What does an autoclave kill? Achieve Complete Sterilization for Your Lab

- What is the alternative method of sterilization for culture media if autoclaving is not suitable? Protect Heat-Sensitive Components

- What is the best sterilization method in microbiology? Match the Method to Your Material for Optimal Results

- What are the limitations and disadvantages of autoclaves? Ensure Sterilization Success by Avoiding Common Pitfalls

- Why is a laboratory autoclave necessary for carbohydrate composition analysis? Unlock Accurate Sugar Yields

- Why must AISI 321 stainless steel samples be treated in an autoclave? Ensure Sterile Precision in Blood Culture Tests

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What does an autoclave do to microorganisms? How It Achieves Sterilization with Steam