In magnetron sputtering, magnets are placed behind the target to create a magnetic field that traps electrons near the target's surface. This confinement dramatically increases the ionization efficiency of the sputtering gas (typically Argon). The resulting dense plasma bombards the target with far more ions, leading to a significantly faster, more controlled, and lower-temperature deposition process compared to sputtering without magnets.

The fundamental challenge in sputtering is creating a dense, stable plasma precisely where it's needed: directly in front of the target material. The magnets solve this by forming a "magnetic cage" for electrons, supercharging the creation of ions that do the actual work of sputtering the target.

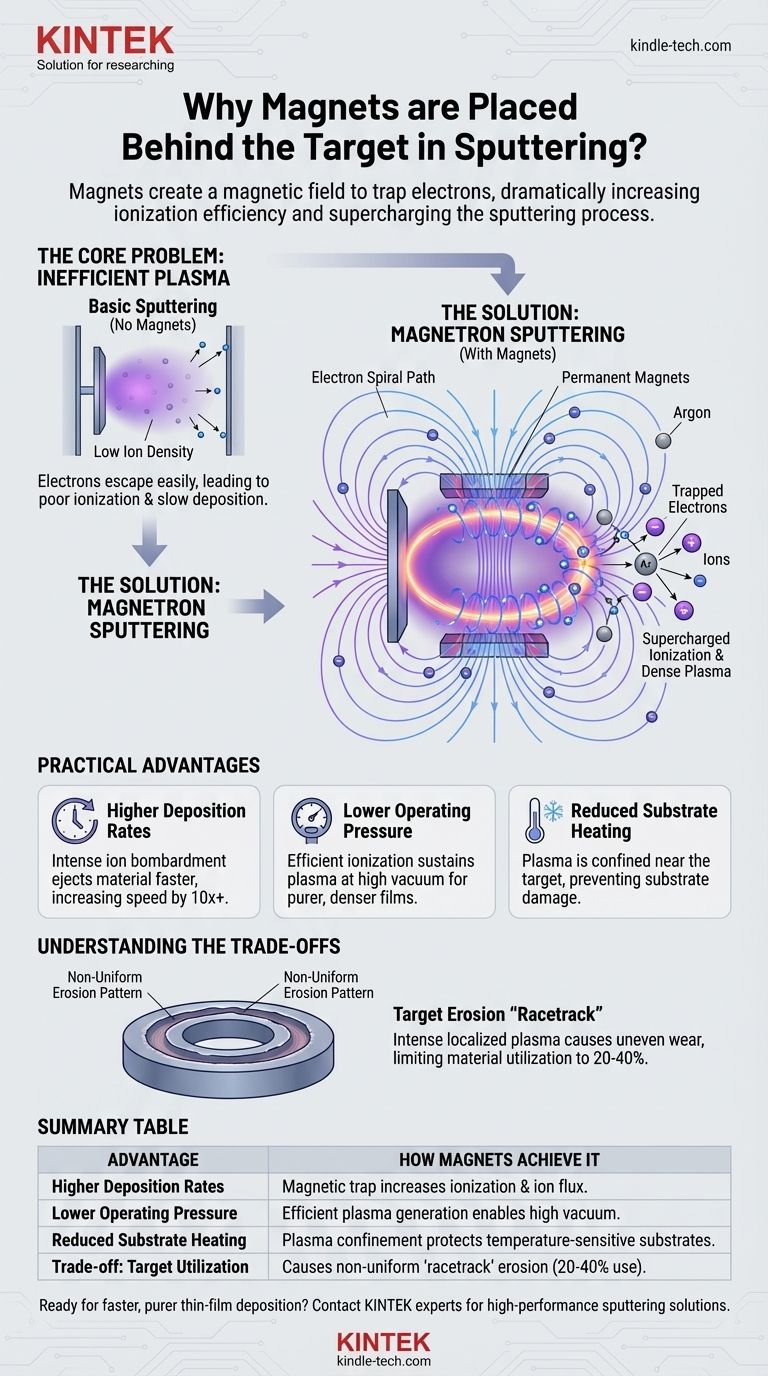

The Core Problem: Inefficient Plasma

The Role of Plasma in Sputtering

Sputtering works by accelerating positively charged gas ions (like Argon, Ar+) into a negatively charged target. These high-energy collisions physically knock atoms off the target material, which then travel and deposit as a thin film onto a substrate. To get a useful deposition rate, you need a high concentration of these Ar+ ions.

The Inefficiency of Basic Sputtering

In a simple sputtering system without magnets (diode sputtering), plasma generation is inefficient. Free electrons, which are essential for ionizing the neutral Argon gas atoms through collisions, are quickly drawn to and lost at the anode (the chamber walls). To compensate, operators must use high gas pressures, which can lead to lower-quality films with trapped gas impurities.

How Magnets Revolutionize the Process

Creating the Electron Trap

By placing strong permanent magnets behind the sputtering target, a magnetic field is generated with lines of flux that emerge from the target, loop around in front of its surface, and re-enter. This creates a closed-loop magnetic tunnel directly in front of the target.

The Electron's Spiral Path

Electrons are lightweight, charged particles that are heavily influenced by magnetic fields. As they are accelerated away from the target, they are captured by this magnetic field and forced to travel in a long, spiral (helical) path along the field lines. They are effectively trapped and can no longer escape directly to the chamber walls.

Supercharging Ionization

An electron trapped in this long spiral path travels a much greater distance near the target before being lost. This massively increases its probability of colliding with a neutral Argon atom. Each collision has a chance to knock an electron off the Argon atom, creating a new Ar+ ion and another free electron, which also becomes trapped. This cascade effect creates a very dense, self-sustaining plasma concentrated right where it is most effective.

The Practical Advantages of Magnetron Sputtering

Higher Deposition Rates

The highly concentrated plasma bombards the target with a much higher flux of ions. This ejects target material at a much faster rate, increasing deposition speeds by an order of magnitude or more compared to non-magnetron systems.

Lower Operating Pressure

Because the magnetic field makes ionization so efficient, a dense plasma can be sustained at much lower gas pressures. Sputtering in a higher vacuum reduces the chance of sputtered atoms colliding with gas atoms on their way to the substrate, leading to purer, denser films with better adhesion.

Reduced Substrate Heating

The magnetic field confines the plasma and electrons near the target, preventing many of these high-energy particles from bombarding and heating the substrate. This allows for the coating of temperature-sensitive materials like plastics or polymers without causing damage.

Understanding the Trade-offs

Non-Uniform Target Erosion (The "Racetrack")

The magnetic trap is not uniform across the entire target face; it is strongest where the magnetic field lines are parallel to the target surface. This intense, localized plasma causes the target to erode much faster in a specific ring or oval pattern, often called a "racetrack."

Limited Material Utilization

Because of the racetrack effect, sputtering must be stopped when the groove becomes too deep, even though a significant amount of target material remains unused outside this area. This leads to lower overall material utilization, typically only 20-40% of the target is consumed.

Making the Right Choice for Your Goal

The advantages of magnetron sputtering have made it the industry standard for most physical vapor deposition (PVD) applications. Understanding the principle helps you align the process with your goals.

- If your primary focus is high-throughput and speed: Magnetron sputtering is the definitive choice due to its vastly superior deposition rates.

- If your primary focus is high-purity films: The ability to operate at low pressure is a critical advantage, minimizing gas incorporation and improving film density.

- If your primary focus is coating temperature-sensitive substrates: The reduced thermal load from confined plasma is essential for preventing damage to materials like plastics and organics.

Ultimately, placing magnets behind the target transforms sputtering from a brute-force process into a precise and highly efficient thin-film deposition technology.

Summary Table:

| Advantage | How Magnets Achieve It |

|---|---|

| Higher Deposition Rates | Magnetic field traps electrons, increasing ionization and ion bombardment on the target. |

| Lower Operating Pressure | Efficient plasma generation allows for a higher vacuum, leading to purer films. |

| Reduced Substrate Heating | Plasma is confined near the target, preventing high-energy particles from damaging the substrate. |

| Trade-off: Target Utilization | Causes non-uniform 'racetrack' erosion, limiting material use to 20-40%. |

Ready to achieve faster, purer thin-film deposition with magnetron sputtering?

KINTEK specializes in high-performance lab equipment and consumables for all your sputtering needs. Our expertise ensures you get the right solution for high-throughput, high-purity, or temperature-sensitive coating applications.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and efficiency!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition