battery material

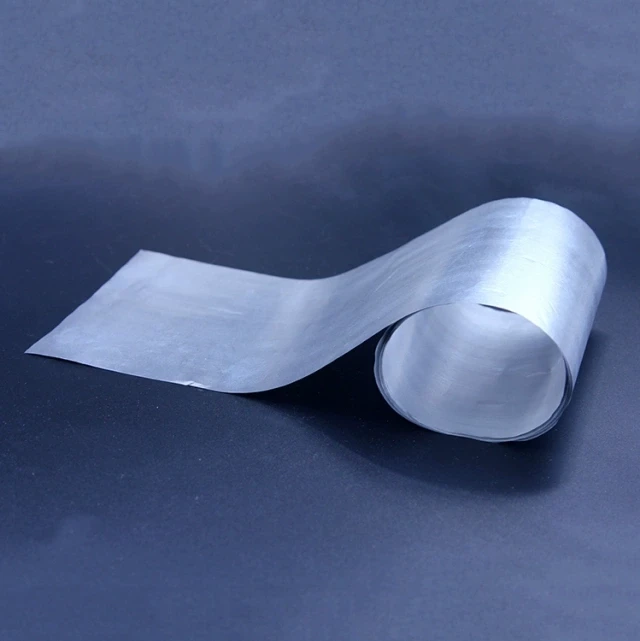

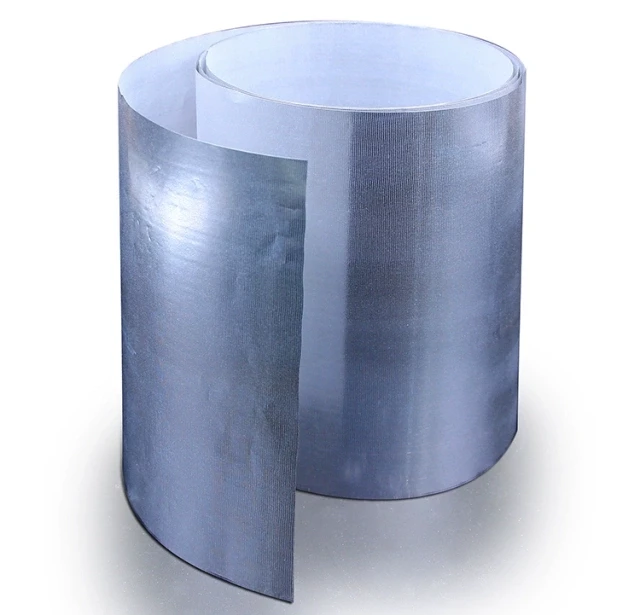

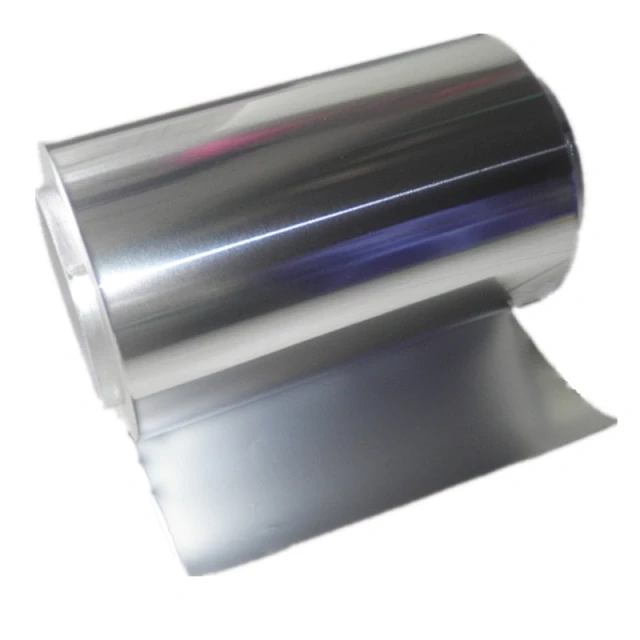

Aluminum Foil Current Collector for Lithium Battery

Item Number : BC-13

Price varies based on specs and customizations

- Material

- aluminum foil

- Size

- 17cm*10m 17cm*20m

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

The surface of aluminum foil is extremely clean and hygienic, and no bacteria or microorganisms can grow on it. Has good oxidation resistance, is a non-toxic, odorless, low density of 2.70; relatively low melting point; high boiling point; can be used in various high-temperature applications. Lightweight; malleable and ductile; can be easily shaped and formed into various shapes such as rods, sheets, foils, ribbons, and wires. packaging materials.

Aluminum foil is generally widely used:

- Lithium battery: Aluminum foil is used as a current collector in various lithium batteries to enhance adhesion and tensile strength.

- Food packaging: Aluminum foil is widely used as food packaging material because of its hygienic, non-toxic and tasteless characteristics.

- Industry: Aluminum foil is used in aerospace, construction and automotive industries due to its unique properties and light weight.

- Energy storage: used in energy storage devices such as fuel cells, power batteries, and energy storage power stations.

Detail & Parts

Technical specifications

| model | thickness | width/mm | Surface density g/m2 | pull | pull | Elongation % |

| 20±um | 53±2 | ≥26N/cm | (back) | ≥1.8 | ||

| single sided light | 20 | 170 | 53.48 | 33 | 57 | 1.82 |

The products we show are available in different sizes and custom sizes are available on request.

Advantages

- Hygienic and sterile: the surface of aluminum foil is clean, preventing the growth of bacteria and microorganisms, ensuring the safety of packaged food.

- Non-toxic, odorless and tasteless: Aluminum foil is safe for direct contact with food and will not cause any health risks to the human body. Can retain the original flavor of food.

- Moisture Barrier: Aluminum foil prevents packaged food from drying out or shrinking, maintaining its freshness and moisture content.

- Grease Resistance: Does not allow grease or oil to penetrate, maintaining package integrity and preventing leaks.

- Light-shielding and UV-resistant: Aluminum foil is opaque and protects against sunlight, making it suitable for light-sensitive products.

- Versatility: Aluminum foil can be easily formed for packaging products of various shapes and sizes.

- Hardness and Tensile Strength: Aluminum foil has high hardness and tensile strength, making it suitable for various packaging applications.

- Tear Resistance: Although aluminum foil has a high tensile strength, it can tear relatively easily.

Trusted by Industry Leaders

4.8 / 5

The aluminum foil current collector is of remarkable quality, ensuring the efficient functioning of our lithium batteries.

4.7 / 5

The prompt delivery and exceptional customer service made my experience with KINTEK SOLUTION exceptional.

4.9 / 5

The aluminum foil current collector is a testament to KINTEK SOLUTION's commitment to innovation and technological advancement.

4.6 / 5

The affordability and durability of the product make it a cost-effective choice for our laboratory.

4.8 / 5

The aluminum foil current collector's remarkable quality and durability have significantly enhanced our battery performance.

4.9 / 5

The product arrived promptly, exceeding our expectations and allowing us to continue our research uninterrupted.

4.7 / 5

The aluminum foil current collector has proven to be a reliable and durable component in our lithium battery setup.

4.6 / 5

The product's quality and performance have met our expectations, making it a worthwhile investment.

4.8 / 5

The aluminum foil current collector has significantly improved the performance and lifespan of our lithium batteries.

4.7 / 5

The product's durability and resistance to wear and tear make it an excellent choice for our demanding applications.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

Professional tools for cutting lithium sheets, carbon paper, carbon cloth, separators, copper foil, aluminum foil, etc., with round and square shapes and different sizes of blades.

Nickel Aluminum Tabs for Soft Pack Lithium Batteries

Nickel tabs are used to manufacture cylindrical and pouch batteries, and positive aluminum and negative nickel are used to produce lithium-ion and nickel batteries.

Battery Lab Equipment Battery Capacity and Comprehensive Tester

The scope of application of the battery comprehensive tester can be tested: 18650 and other cylindrical, square lithium batteries, polymer batteries, nickel-cadmium batteries, nickel-metal hydride batteries, lead-acid batteries, etc.

Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

Multi zone rotary furnace for high-precision temperature control with 2-8 independent heating zones. Ideal for lithium ion battery electrode materials and high-temperature reactions. Can work under vacuum and controlled atmosphere.

Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

Efficiently calcine and dry bulk powder and lump fluid materials with an electric heating rotary furnace. Ideal for processing lithium ion battery materials and more.

Related Articles

Design and Application of Reference Electrodes in Lithium Batteries

This article discusses the selection and design of reference electrodes for lithium batteries, focusing on active materials like lithium metal, lithium alloys, and lithium-embedded oxides.

Carbon Coating for Surface Modification of Silicon-Based Materials in Lithium-Ion Batteries

This article discusses the application of carbon coatings to improve the performance of silicon-based anode materials in lithium-ion batteries.

Design Principle and Application of Reference Electrodes for Lithium Batteries

Discusses the design principles, types, applications, and future directions of reference electrodes in lithium batteries.

PTFE gasket: an all-around solution for flange sealing

Polytetrafluoroethylene (PTFE) gaskets have become an ideal choice in the field of flange sealing due to their unique chemical stability and high temperature resistance.

Preparation Technologies and Applications of High-Purity Metals

An in-depth look at the definition, preparation technologies, and applications of high-purity metals.