General Considerations for Large Optical Windows

Environmental and Operational Factors

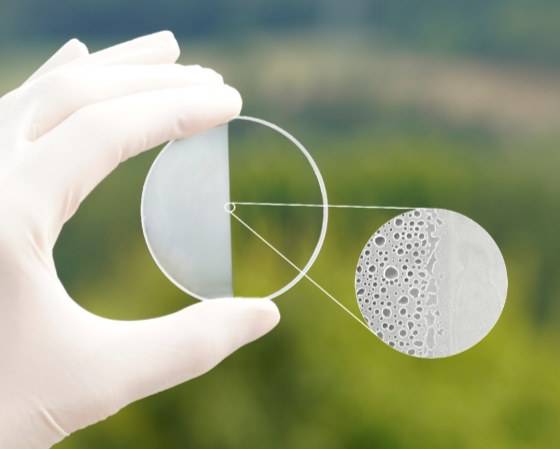

Larger optical windows are often deployed in outdoor settings or environments where they are continuously exposed to various contaminants, such as dust, moisture, and chemical pollutants. These contaminants can significantly degrade the surface quality of the windows, affecting their optical performance. To mitigate these issues, periodic maintenance is essential. This includes repolishing the windows to restore their surface smoothness and recoating them with protective layers, such as anti-reflective (AR) coatings. These maintenance procedures not only enhance the longevity of the windows but also offer substantial cost savings in the long run by extending their operational lifespan and reducing the frequency of replacement.

Moreover, the operational conditions in which these large optical windows are used can vary widely, from high-pressure environments to extreme temperature fluctuations. These conditions can accelerate the wear and tear on the windows, necessitating more frequent maintenance cycles. Therefore, understanding the specific environmental and operational challenges is crucial for designing effective maintenance strategies that ensure the optimal performance of large optical windows.

Weight Considerations

The weight of large optical windows is a critical factor that influences various stages of their lifecycle, from sourcing raw materials to the final installation. The heaviness of these windows directly impacts the cost and feasibility of material procurement, as heavier materials often require specialized handling and transportation.

In the processing phase, the weight of the material can significantly increase production costs. Heavier windows necessitate more robust machinery and techniques to shape and polish, which can be both time-consuming and expensive. Additionally, the weight affects the coating process; thicker or denser materials require more layers of protective coatings, further escalating costs.

Installation is another critical area where weight plays a pivotal role. Large optical windows, particularly those used in aerospace and defense, must be installed with precision and stability. The weight of these windows necessitates strong mounting structures and careful engineering to ensure they can withstand operational stresses without compromising their optical integrity. Thus, the weight of large optical windows is not merely a technical detail but a major consideration that can influence the entire project's feasibility and cost.

Applications and Shapes of Large Optical Windows

Common Applications

Large optical windows are integral components across a spectrum of advanced technological fields. In aerospace, these windows serve as critical elements in spacecraft and satellites, enabling clear optical communication and observation. Astronomy benefits significantly from large windows, as they facilitate the capture of high-resolution images and data from distant celestial bodies. The defense sector utilizes these windows for various surveillance and targeting systems, ensuring precision and clarity in mission-critical operations.

In the realm of free-space optical communications, large windows are indispensable for maintaining high-bandwidth data links over long distances. High laser energy research relies on these windows to safely contain and direct powerful laser beams, supporting groundbreaking scientific experiments. Additionally, lidar systems, crucial for autonomous vehicles and environmental mapping, depend on large windows to provide accurate, real-time data collection. Each of these applications underscores the vital role that large optical windows play in advancing modern technology and scientific exploration.

Shape Variations

Large optical windows exhibit a diverse array of shapes tailored to specific applications. These shapes can range from the conventional circular and rectangular forms to more specialized geometries such as square, oval, and even irregular configurations. The choice of shape is often dictated by the functional requirements of the application, which may necessitate unique optical properties or mechanical constraints.

For instance, circular windows are commonly employed in applications requiring uniform light transmission across a wide field of view, such as in astronomy and aerospace. Rectangular and square windows, on the other hand, are often preferred in situations where space is limited or where a specific aspect ratio is beneficial, such as in certain types of laser systems.

Oval and irregularly shaped windows offer flexibility in design, allowing for integration into systems with complex geometries or where optical performance needs to be optimized for non-standard viewing angles. This versatility is particularly valuable in advanced research and defense applications, where the ability to adapt to unique operational conditions is paramount.

| Shape | Common Applications |

|---|---|

| Circular | Astronomy, Aerospace, Free-space Optical Communications |

| Rectangular | Laser Systems, Lidar, High Laser Energy Research |

| Square | Compact Systems, Limited Space Applications |

| Oval | Custom Optical Systems, Non-standard Viewing Angles |

| Irregular | Advanced Research, Defense, Complex Geometries |

The selection of window shape is not merely a cosmetic decision but a critical factor that impacts the overall performance and efficiency of the optical system. Each shape carries inherent advantages and limitations, making it essential to match the window geometry with the specific demands of the application.

Materials for Large Optical Windows

Common Materials

When selecting materials for large optical windows, a variety of options are available, each tailored to specific spectral ranges and applications. For visible spectroscopy, materials such as BK7, Borofloat/Supremax, and fused silica plates are commonly used due to their excellent optical properties and stability. BK7, a borosilicate glass, offers a good balance of cost and performance, making it a popular choice for many applications. Borofloat/Supremax, another borosilicate glass, provides enhanced thermal and mechanical properties, making it suitable for more demanding environments. Fused silica plates, known for their high purity and low thermal expansion, are ideal for applications requiring high precision and stability.

In the infrared spectrum, different materials are selected to accommodate the unique demands of this range. Germanium lenses, silicon, zinc selenide, and zinc sulfide are frequently used for their high transmittance in the infrared region. Germanium lenses, although relatively expensive, offer high refractive indices and are commonly used in thermal imaging and night vision systems. Silicon, another popular choice, is known for its durability and high thermal conductivity, making it suitable for high-temperature applications. Zinc selenide and zinc sulfide, both known for their wide transmission windows, are often used in applications requiring high-energy laser transmission and thermal imaging.

Each of these materials has its own set of advantages and limitations, making material selection a critical step in the design and implementation of large optical windows. The choice of material not only affects the optical performance but also influences the overall cost, weight, and durability of the window. Therefore, careful consideration must be given to the specific requirements of the application to ensure the optimal material is selected.

Material Properties

When selecting materials for large optical windows, several key properties must be considered to ensure optimal performance and stability. Transmissivity is paramount, as it determines how effectively the material can transmit light across a spectrum, which is crucial for applications ranging from visible spectroscopy to infrared imaging. Materials like fused silica plates and germanium lenses are highly transmissive in their respective spectra, making them ideal for specific applications.

Homogeneity is another critical factor. A homogeneous material ensures that the optical properties are uniform throughout the window, preventing distortions and aberrations that could compromise the quality of the transmitted light. This uniformity is particularly important in high-precision applications such as astronomy and high laser energy research, where even minor inconsistencies can lead to significant errors.

Annealing is a process that enhances the stability of the material by reducing internal stresses. Annealed materials are less likely to deform or crack under thermal or mechanical stress, making them more durable and reliable in demanding environments. For instance, borosilicate glass like Borofloat undergoes annealing to improve its thermal shock resistance, which is essential for applications involving rapid temperature changes.

| Property | Importance | Examples |

|---|---|---|

| Transmissivity | Determines light transmission efficiency across a spectrum. | Fused silica plates (visible), Germanium lenses (infrared) |

| Homogeneity | Ensures uniform optical properties, preventing distortions. | Borofloat, Supremax |

| Annealing | Reduces internal stresses, improving stability and durability. | Borosilicate glass, Silicon |

These properties collectively contribute to the overall performance and longevity of large optical windows, making them suitable for a wide range of critical applications.

Polishing and Testing Methods

Polishing Techniques

When it comes to polishing large optical windows, the choice between one-sided and two-sided techniques hinges largely on the scale of production. For single pieces or small batches, one-sided polishing is often preferred due to its precision and the ability to focus on individual surface characteristics. This method allows for meticulous attention to detail, ensuring that each window meets the stringent requirements necessary for optimal performance.

On the other hand, two-sided polishing is employed for larger quantities, where efficiency and uniformity are paramount. This technique not only speeds up the production process but also ensures that both sides of the window are polished to the same exacting standards. This dual-sided approach is particularly beneficial for applications requiring high throughput and consistent quality across multiple units.

The critical metric in assessing the effectiveness of these polishing methods is the Transmission Wavefront Error (TWE). TWE quantifies the deviation of the transmitted wavefront from an ideal reference wavefront, which is crucial for maintaining the optical performance of the window. A lower TWE indicates a higher quality polish, resulting in superior optical clarity and minimal distortion. Therefore, regardless of the polishing technique used, achieving a low TWE is essential for ensuring that the large optical windows meet their intended performance criteria.

Testing Methods

The precision of large optical windows is paramount, especially when they are intended for applications in aerospace, astronomy, and defense. To ensure that these windows meet the stringent performance requirements, advanced testing methods are employed. One such method is the use of phase-shifted, large-aperture interferometers. These sophisticated instruments are designed to measure the transmitted wavefront with high accuracy, providing insights into the optical quality of the window.

Interferometers work by splitting a light beam into two paths: a reference path and a test path. The test path passes through the window being evaluated, while the reference path does not. When the two beams are recombined, any discrepancies in the wavefront caused by imperfections in the window material or surface will result in interference patterns. These patterns are analyzed to determine the exact nature and extent of the imperfections.

The use of phase-shifted interferometers adds an extra layer of precision. By introducing controlled phase shifts between the reference and test beams, the interferometer can more accurately map out the wavefront errors. This is particularly crucial for large windows, where even minor deviations can significantly impact performance.

In summary, the combination of large-aperture and phase-shifted interferometers provides a robust testing method for large optical windows, ensuring that they meet the high standards required for their intended applications.

Coating and Packaging Considerations

Coating Requirements

When selecting large optical windows, the application of anti-reflective (AR) coatings is essential to enhance optical performance. These coatings not only reduce unwanted reflections but also improve light transmission, which is crucial for various applications such as aerospace and astronomy.

In addition to AR coatings, optional enhancements like oleophobic and hydrophobic properties can be added. These additional coatings serve to protect the window surfaces from contaminants, such as fingerprints and water droplets, which can degrade optical clarity over time.

Coating uniformity is a critical factor that cannot be overlooked. The quality of the coating layer must meet several stringent requirements:

- Adhesion: The coating must be firmly bonded to the base material, ensuring it does not peel or flake off under operational conditions.

- Completeness: The coating should be uniform across the entire surface, with fine and compact crystallization to minimize porosity.

- Properties: The coating must exhibit good physical, chemical, and mechanical properties to withstand environmental stress and operational demands.

- Thickness: The coating thickness must adhere to standard specifications, with even distribution to prevent any localized weaknesses or performance discrepancies.

Ensuring these quality standards are met is vital for maintaining the integrity and functionality of large optical windows in demanding environments.

Packaging Methods

Large optical windows require meticulous packaging to ensure they arrive at their destination in pristine condition. These windows are often shipped in robust, hard cases designed to withstand the rigors of transportation. Inside these cases, protective internal packaging materials, such as foam inserts or custom-fitted cradles, provide an additional layer of security, preventing any movement that could cause damage during transit.

In some high-stakes applications, such as those in the aerospace or defense sectors, large optical windows are handled within controlled environments like cleanrooms. These environments minimize the risk of contamination from dust and other particulates, which could otherwise compromise the optical integrity of the windows. Cleanroom packaging protocols ensure that the windows remain free from contaminants from the moment they are packaged until they are installed in their final application.

| Packaging Method | Description |

|---|---|

| Hard Cases with Foam Inserts | Hard cases with protective foam inserts or custom-fitted cradles for stability. |

| Cleanroom Environments | Controlled environments that minimize contamination risk during handling. |

The choice of packaging method is influenced by the specific requirements of the application and the sensitivity of the optical windows. For instance, windows used in high-precision astronomy or laser research might necessitate the highest level of protection and cleanliness, necessitating cleanroom packaging. Conversely, less sensitive applications might rely solely on hard cases with internal packaging.

Regardless of the method chosen, the goal remains the same: to ensure that the large optical windows arrive at their destination in the same condition they were in when they left the manufacturing facility. This attention to detail in packaging is crucial for maintaining the performance and longevity of these critical components.

Related Products

- CVD Diamond Optical Windows for Lab Applications

- Optical Window Glass Substrate Wafer CaF2 Substrate Window Lens

- KF Ultra-High Vacuum Observation Window 304 Stainless Steel Flange High Borosilicate Glass Sight Glass

- 400-700nm Wavelength Anti Reflective AR Coating Glass

- Zinc Selenide ZnSe Optical Window Glass Substrate Wafer and Lens

Related Articles

- Optical Quartz Plate: A Comprehensive Guide to Applications, Specifications, and Usage

- Unlocking the Power of Optical Quartz Plates: Applications and Benefits

- CVD Diamond Optical Windows: Advancing High-Tech Optical Applications in Extreme Environments

- The Ethics of Diamond Growing Machines

- Advancements in Diamond Optical Window-Related Components