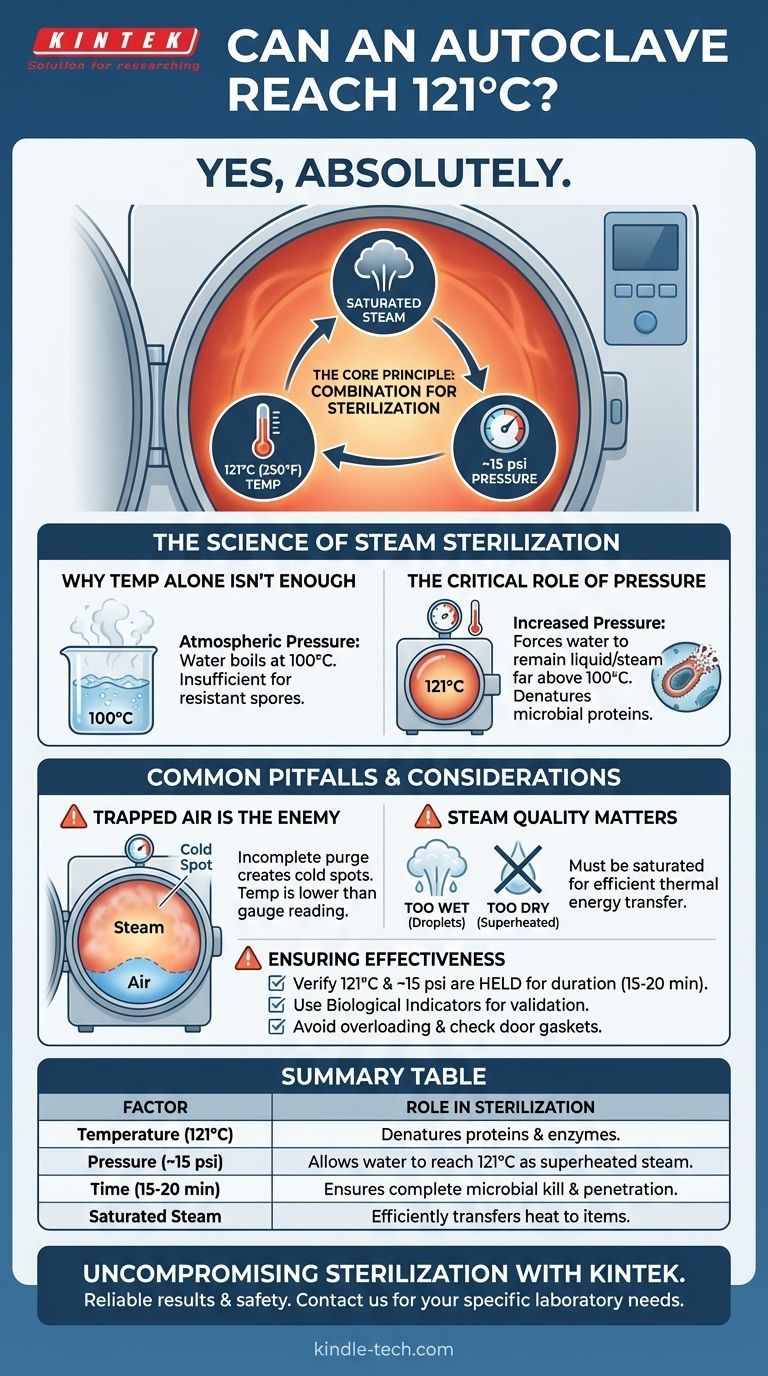

Yes, absolutely. Not only can an autoclave reach 121° Celsius, but this specific temperature is the most fundamental and universally recognized standard for steam sterilization. This temperature is achieved by using a combination of heat and pressure inside a sealed chamber, which allows water to exist as superheated, saturated steam far above its normal boiling point.

The core principle to understand is that effective sterilization isn't just about heat. It is the combination of saturated steam, elevated temperature (121°C), and increased pressure (~15 psi) that work in unison to reliably destroy all forms of microbial life, including resilient bacterial spores.

The Science of Steam Sterilization

To understand why 121°C is the target, we must first understand the relationship between water, pressure, and heat. This interplay is the entire basis of how an autoclave functions.

Why Temperature Alone Isn't Enough

At sea-level atmospheric pressure, water boils at 100°C (212°F). At this temperature, it turns into steam and can't get any hotter. While hot, this is not sufficient to guarantee the destruction of highly resistant microorganisms like bacterial spores.

To achieve the higher temperatures needed for sterilization, we need to change the rules.

The Critical Role of Pressure

An autoclave is essentially a highly sophisticated pressure cooker. By sealing the chamber and pumping in steam (or boiling water within it), the internal pressure dramatically increases.

This increased pressure forces the water molecules to remain in a liquid/steam state at temperatures far beyond 100°C. This is the physical principle that makes sterilization possible.

How 121°C Became the Standard

The temperature of 121°C (250°F), achieved at a pressure of approximately 15 pounds per square inch (psi) above atmospheric pressure, is the established benchmark.

At this specific temperature, the moist heat from saturated steam is incredibly effective at denaturing the essential proteins and enzymes that all microorganisms rely on to live. Maintaining this condition for a set duration (typically 15-20 minutes) ensures even the most heat-resistant spores are inactivated.

Common Pitfalls and Considerations

Simply seeing "121°C" on the display does not guarantee successful sterilization. The effectiveness of the process is dependent on the precise conditions inside the chamber.

Trapped Air is the Enemy

The most common cause of sterilization failure is trapped air. If the air is not fully purged from the chamber, the pressure gauge may read 15 psi, but this will be a combination of air and steam pressure.

This means the actual temperature of the steam will be significantly lower than the required 121°C, creating cold spots and rendering the cycle ineffective.

The Importance of Saturated Steam

The goal is to achieve saturated steam—a state where the steam holds the maximum amount of water vapor possible at that specific temperature and pressure.

If the steam is too "wet" (containing excess water droplets) or too "dry" (superheated), its ability to transfer thermal energy efficiently to the items being sterilized is compromised.

Time is the Third Variable

Reaching 121°C is only the first step. This temperature must be held for a sufficient duration to ensure the steam fully penetrates the load and kills all microorganisms. The standard time is often 15 minutes, but this can vary based on the size and density of the items being sterilized.

Ensuring Effective Sterilization

Understanding these principles allows you to use an autoclave not just as a machine, but as a precise scientific instrument.

- If your primary focus is routine sterilization: Verify that your cycle consistently reaches and holds 121°C at ~15 psi for the entire required duration, not just for a moment.

- If your primary focus is validating a process: Use biological indicators (containing spores of Geobacillus stearothermophilus) placed in the most challenging parts of your load to prove the cycle achieves a complete kill.

- If you are troubleshooting a failed cycle: Before re-running, check for common errors like overloading the chamber, using sealed containers, or a faulty door gasket that could prevent proper steam penetration and pressure buildup.

Mastering the relationship between temperature, pressure, and time is the key to achieving reliable and verifiable sterilization every single time.

Summary Table:

| Key Factor | Role in Sterilization |

|---|---|

| Temperature (121°C) | Denatures proteins and enzymes in microorganisms. |

| Pressure (~15 psi) | Allows water to reach 121°C as superheated steam. |

| Time (15-20 min) | Ensures complete microbial kill and steam penetration. |

| Saturated Steam | Efficiently transfers heat to the items being sterilized. |

Ensure Your Lab's Sterilization is Uncompromising

Achieving and maintaining the precise 121°C standard is critical for reliable results and safety. KINTEK specializes in high-performance lab equipment and consumables, providing autoclaves and validation tools trusted by laboratories worldwide.

Let our experts help you select the right equipment or troubleshoot your sterilization process. Contact KINTEK today to discuss your laboratory's specific needs.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy