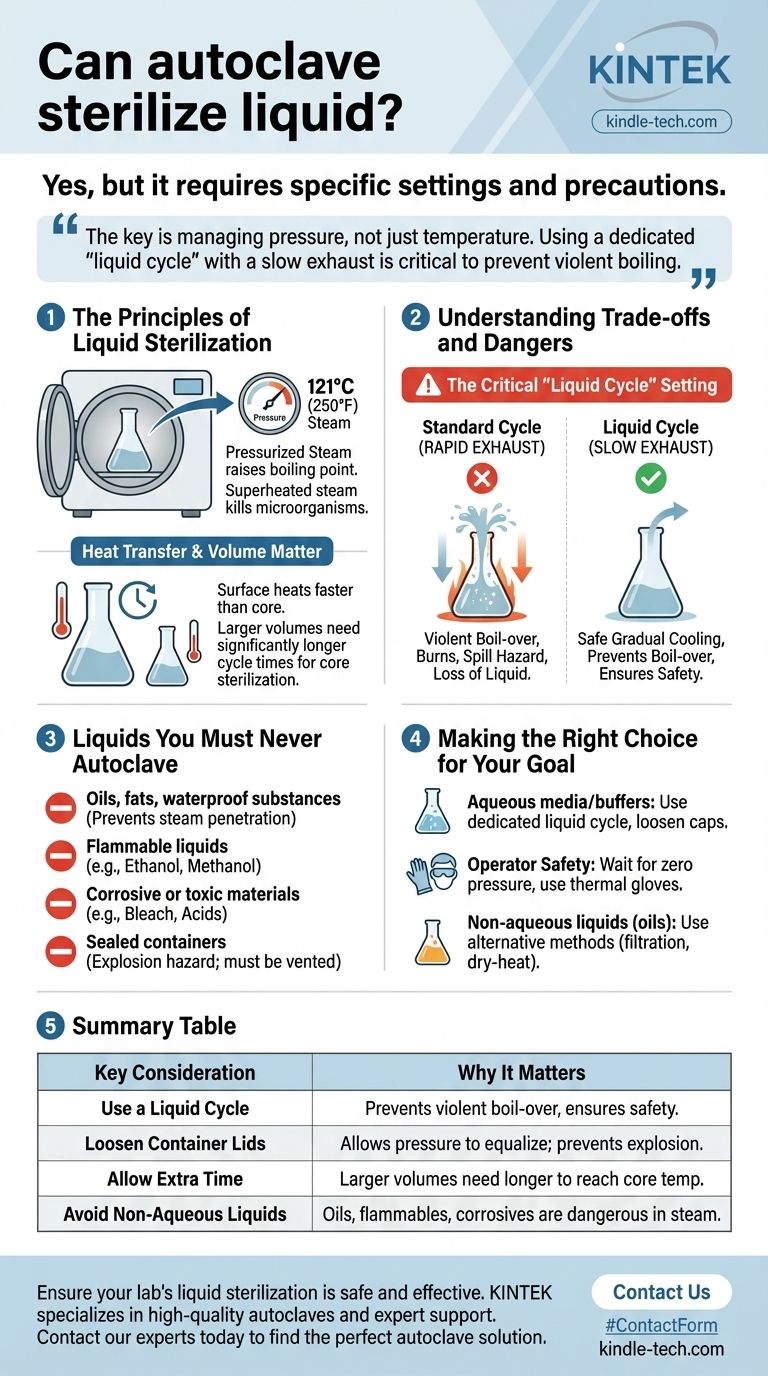

Yes, you can sterilize liquids in an autoclave, provided they are primarily water-based. In fact, autoclaves are specifically designed for this purpose, using high-pressure steam to reliably eliminate microorganisms. However, the process for liquids is fundamentally different from that for solid goods and requires specific settings and safety precautions to be effective and safe.

The key to successfully autoclaving liquids is not just about reaching a target temperature, but about managing pressure. Using a dedicated "liquid cycle" with a slow exhaust is critical to prevent violent boiling and ensure the entire liquid volume is properly sterilized.

The Principles of Liquid Sterilization

How Pressurized Steam Works

An autoclave doesn't just boil water; it uses pressure to raise the boiling point of water far beyond 100°C (212°F). This superheated steam, typically at 121°C (250°F), is what kills bacteria, viruses, and even heat-resistant spores.

The pressurized steam transfers thermal energy with extreme efficiency, ensuring the entire chamber and its contents reach the sterilizing temperature.

Heat Transfer and Volume Matter

A critical factor for liquids is heat transfer lag. The surface of a liquid will heat up much faster than its core.

Therefore, the sterilization timer (e.g., 15 minutes) only begins after the liquid itself, not just the chamber air, has reached the target temperature. Larger volumes of liquid require significantly longer cycle times to ensure the core is fully sterilized.

Understanding the Trade-offs and Dangers

The Critical "Liquid Cycle" Setting

The most common and dangerous mistake is using a standard (gravity or vacuum) cycle for liquids. These cycles end with a rapid release of pressure.

When the pressure drops suddenly, the superheated liquid inside your container will boil violently and erupt, a phenomenon known as boil-over. This can cause severe burns, spill potentially hazardous materials, and result in a significant loss of your liquid.

A dedicated liquid cycle releases pressure slowly, allowing the liquid to cool gradually below its boiling point before the chamber pressure returns to normal, preventing this hazardous situation.

Liquids You Must Never Autoclave

Steam sterilization relies entirely on the interaction of heat and water. If a substance repels water or reacts dangerously to heat and pressure, it cannot be autoclaved.

This includes:

- Oils, fats, or other oily substances, as they are waterproof and prevent steam penetration.

- Flammable liquids like ethanol or methanol.

- Corrosive or toxic materials, such as bleach or acids.

- Sealed containers, which will explode under pressure. All containers must be vented or have loosened caps to allow pressure to equalize.

Making the Right Choice for Your Goal

To ensure you are sterilizing liquids both safely and effectively, follow this guidance.

- If your primary focus is sterilizing aqueous media or buffers: Always use a dedicated liquid cycle on your autoclave and ensure container caps are loosened to permit venting.

- If your primary focus is operator safety: Never open the autoclave until the pressure has returned to zero, and always handle the hot glassware with thermal-protective gloves.

- If you need to sterilize non-aqueous liquids like oils: An autoclave is the wrong tool; you must use an alternative method like filtration or dry-heat sterilization.

By understanding the unique physics of heating liquids under pressure, you can use the autoclave to achieve safe and reliable sterilization.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Use a Liquid Cycle | Prevents violent boil-over by slowly releasing pressure, ensuring safety. |

| Loosen Container Lids | Allows pressure to equalize; sealed containers can explode. |

| Allow Extra Time | Larger liquid volumes need longer cycles for the core to reach sterilizing temperature. |

| Avoid Non-Aqueous Liquids | Oils, flammables, and corrosives cannot be sterilized by steam and are dangerous. |

Ensure your lab's liquid sterilization is both safe and effective. Autoclaving liquids requires specific protocols and reliable equipment to prevent dangerous accidents and ensure complete sterility. KINTEK specializes in high-quality autoclaves and expert support for all your laboratory sterilization needs.

Contact our experts today to find the perfect autoclave solution for your lab's specific requirements.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What is the primary purpose of an autoclave in the preparation of media for the biological leaching of uranium?

- Why is a 24-hour hydrothermal treatment in an autoclave necessary for BMO nanosheets? Unlock Superior Photocatalysis

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- Why is the prevention of air entrapment critical for the autoclave sterilization process? Ensure 100% Sterility Today

- What is the necessity of using a steam autoclave for dental alloys? Ensure Pure Bacterial Adhesion Data