No, an infrared camera cannot directly see or detect mold. An infrared (or thermal) camera is a powerful diagnostic tool that measures surface temperature, not the presence of a specific fungus. It excels at identifying the underlying conditions that allow mold to grow, namely hidden moisture.

An infrared camera is an invaluable tool for finding potential mold problems, but it functions as a moisture detector, not a mold detector. It helps you see where mold could be, prompting a more direct investigation.

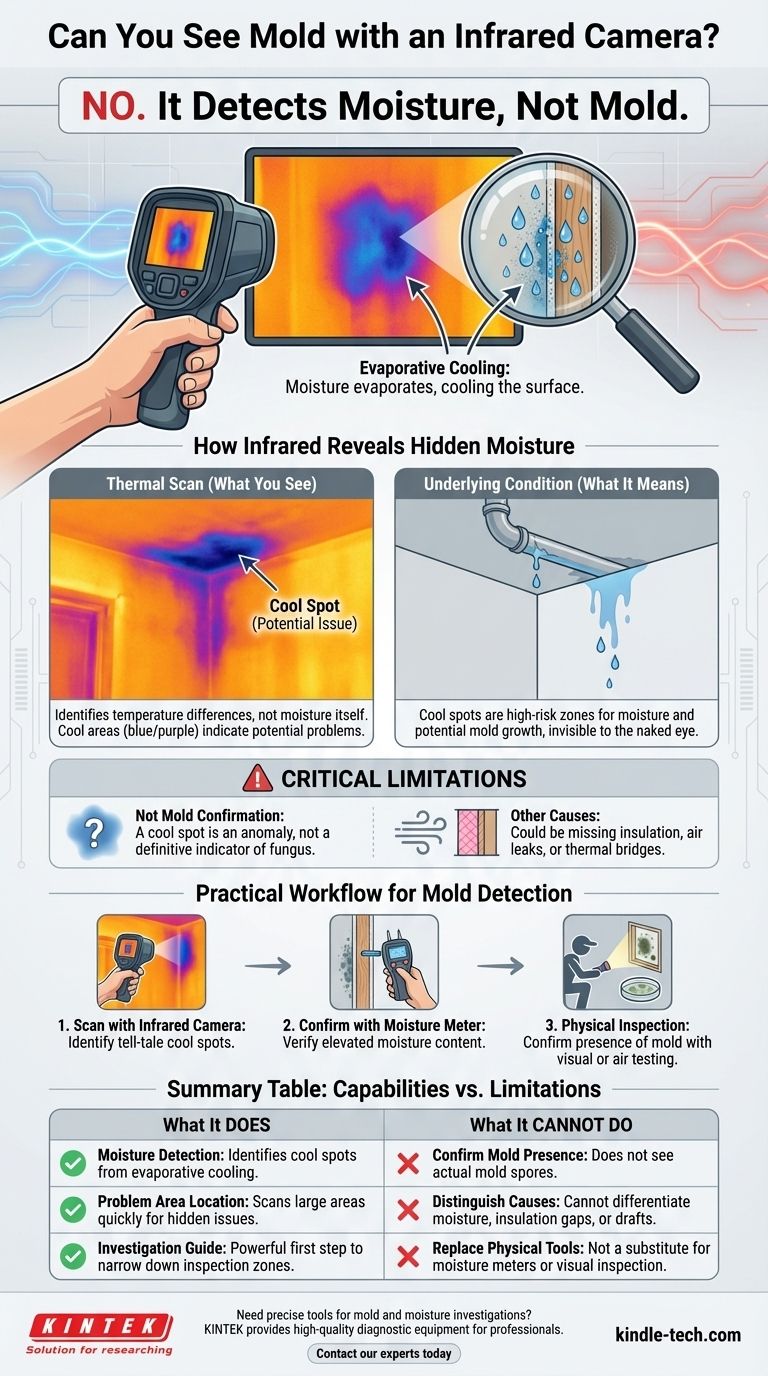

How Infrared Reveals Hidden Moisture

An infrared camera doesn't see moisture; it sees the subtle temperature differences that moisture creates. This allows an inspector to rapidly scan large areas and pinpoint potential problem spots that are completely invisible to the naked eye.

The Principle of Evaporative Cooling

The primary way an infrared camera finds moisture is through the principle of evaporative cooling. As water evaporates from a surface—like drywall or wood—it cools that surface down.

Even a small amount of moisture can create a temperature drop of several degrees. An infrared camera is sensitive enough to detect this difference and display it visually.

Translating Temperature to a Visual Map

The camera translates surface temperatures into a color-coded image. Typically, cooler areas appear as blue or purple, while warmer areas are shown in red, orange, or yellow.

A suspicious dark blue patch on an otherwise yellow wall is an immediate red flag. It indicates that specific spot is colder than the surrounding area, very likely due to the presence of water from a leak or condensation.

Identifying Potential Growth Zones

Because mold requires moisture to cultivate, these cool spots are the high-risk zones. The camera allows you to locate potential moisture behind walls, under floors, in ceilings, and around foundations—places where mold often grows unseen.

Understanding the Critical Limitations

While incredibly useful, it is vital to understand what an infrared camera cannot do. Misinterpreting the data can lead to incorrect conclusions.

It Does Not Confirm Mold

A cool spot is only an anomaly that requires further investigation. It is an indicator of a potential issue, not a confirmation of one.

That cool spot could be a water leak, but it could also be a patch of missing insulation, an air leak from a draft, or a "thermal bridge" caused by a framing stud.

It Is Not a Substitute for Physical Tools

An infrared camera is the first step, not the last. Once a cool anomaly is found, it must be confirmed with a different tool.

A professional will use a moisture meter to physically touch the area and get a quantitative reading of the moisture content in the material. This confirms or denies the presence of water.

A Practical Workflow for Mold Detection

Using an infrared camera correctly involves a clear, multi-step process. It's a tool for narrowing your search, not for providing a final diagnosis.

- If your primary focus is finding a hidden leak: Use an infrared camera as a non-destructive first pass to scan walls and ceilings, looking for the tell-tale cool spots that indicate moisture.

- If your primary focus is confirming a moisture problem: After identifying a cool spot with the camera, use a high-quality moisture meter to verify that the area actually has an elevated moisture content.

- If your primary focus is confirming the presence of mold: Once moisture is confirmed, a physical inspection is required, which may involve air quality testing or removing a small section of drywall for visual confirmation.

Used correctly, an infrared camera transforms the search for mold from a guessing game into a targeted investigation.

Summary Table:

| Capability | What an Infrared Camera Does | What it Cannot Do |

|---|---|---|

| Moisture Detection | Identifies cool spots from evaporative cooling, indicating potential water intrusion. | Cannot confirm the presence of actual mold spores. |

| Problem Area Location | Scans large areas quickly to pinpoint hidden moisture behind walls, under floors, and in ceilings. | Cannot distinguish between moisture, missing insulation, or drafts without further testing. |

| Investigation Guide | Serves as a powerful first step to narrow down areas for further, direct inspection. | Is not a substitute for confirmation tools like a moisture meter or visual inspection. |

Need precise tools for your mold and moisture investigations? KINTEK specializes in high-quality laboratory equipment and consumables, including the diagnostic tools professionals rely on for accurate results. Whether you're in building inspection, environmental testing, or restoration, we provide the reliable equipment you need to confirm your findings with confidence.

Contact our experts today to find the right tools for your specific laboratory and field needs!

Visual Guide

Related Products

- Infrared High Resistance Single Crystal Silicon Lens

- Isostatic Molding Pressing Molds for Lab

- Small Lab Rubber Calendering Machine

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- Is graphite affected by heat? Discover Its Remarkable Strength and Stability at High Temperatures

- What is the high temperature of quartz? Key Thresholds for Crystalline vs. Fused Silica

- What is an alternative to a zeolite catalyst? Exploring MOFs, Mesoporous Silicas & Metal Oxides

- What role does an industrial oven play in the pre-treatment of waste PCBs? Automate Thermal Disassembly with Precision

- What is the purpose of the slow cooling (annealing) process for Ni-TiO2? Ensure Material Stability and Performance

- What are the advantages and limitations of heat treatment? Tailor Material Properties for Peak Performance

- What is the difference between conventional and microwave pyrolysis? Unlock Faster, More Efficient Heating

- How does heat treatment affect hardness? Master the Art of Controlled Hardening and Softening