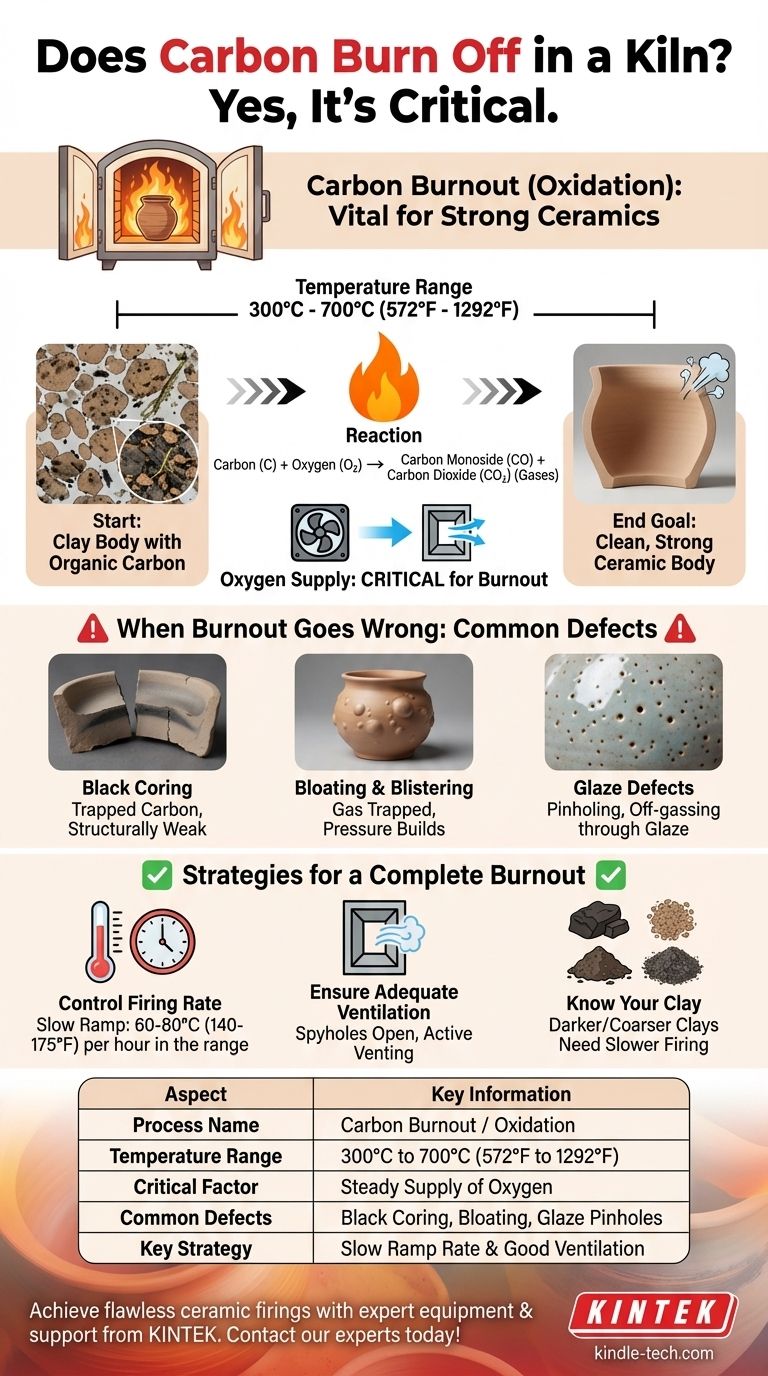

Yes, carbon absolutely burns off in a kiln. This process, known as carbon burnout or oxidation, is a critical and often delicate stage in the firing cycle. It is essential for achieving a strong, durable ceramic body, but if managed incorrectly, it can be the source of serious firing defects.

The burnout of carbon and organic materials from clay is a necessary chemical reaction. The core challenge is ensuring this burnout is complete before the clay surface seals, as trapped carbon can lead to defects like bloating, black coring, and weakness in the final piece.

The Chemistry of Carbon Burnout

What "Carbon" Are We Burning?

When discussing carbon in clay, we are referring to more than just elemental carbon. It includes a range of organic compounds, lignins, and other carbonaceous materials naturally present in raw clays and some additives.

These materials are the remnants of ancient plant and animal life. Darker clays, such as many stoneware and earthenware bodies, typically contain a higher percentage of these compounds.

The Oxidation Reaction

Carbon burnout is an oxidation process. Between approximately 300°C and 700°C (572°F and 1292°F), the carbon in the clay body reacts with oxygen available inside the kiln.

This reaction converts the solid carbon into carbon monoxide (CO) and carbon dioxide (CO2) gases. These gases must be able to escape from the clay body and be vented out of the kiln.

The Critical Role of Oxygen

The chemical reaction cannot happen without a steady supply of oxygen. A kiln that is sealed too tightly or lacks proper ventilation will starve the process.

Without sufficient oxygen, the carbon will remain locked in the clay, setting the stage for problems comportement at higher temperatures.

When Burnout Goes Wrong: Common Defects

If the burnout phase is rushed or starved of oxygen, the carbon does not have time to fully convert to gas and escape. This leads to several common and destructive firing failures.

Black Coring

This is the most direct sign of incomplete burnout. If you break a finished piece and see a black or grey line in the center of the clay wall, you are seeing trapped carbon.

This occurs when the kiln temperature rises too quickly, causing the surface of the clay to vitrify (become glassy and non-porous) before the interior carbon has burned out. The sealed surface prevents oxygen from getting in and CO/CO2 from getting out. A black-cored piece is structurally weak.

Bloating and Blistering

Bloating is the advanced stage of black coring. As the temperature continues to rise past the burnout phase, the trapped carbon will still try to oxidize, creating CO/CO2 gas.

Since the clay surface is already sealed, this gas is trapped. The pressure builds and inflates the clay wall, creating ugly and ruinous bloats or blisters.

Glaze Defects

Incomplete burnout can also ruin your glazes. If the clay body is still releasing gases while the glaze is molten, these gases will bubble up through the glaze.

This off-gassing is a primary cause of pinholing and small blisters in the final glaze surface, compromising its protective function and aesthetic.

Strategies for a Complete Burnout

The key to preventing these defects is giving the carbon three things: time, temperature, and oxygen.

Control Your Firing Rate

The single most effective strategy is to fire slowly through the carbon burnout window (roughly 300°C to 700°C). A slow ramp rate of 60-80°C (140-175°F) per hour in this range is a safe starting point.

This slow pace gives oxygen time to penetrate the clay body and gives the resulting gases time to escape before the surface seals.

Ensure Adequate Ventilation

Your kiln needs to breathe. Keep spyholes open and ensure your kiln vent is running during this phase. This accomplishes two things: it draws fresh, oxygen-rich air into the kiln and actively removes the CO/CO2 being produced.

A well-ventilated kiln atmosphere dramatically improves the efficiency of the burnout process.

Know Your Clay Body

Be aware that darker clays, coarser clays, or clays with high organic content are more demanding. They contain more material that needs to burn out and may require an even slower firing rate and more aggressive ventilation.

Making the Right Choice for Your Firing

- If your primary focus is fixing black coring or bloating: You must slow down your firing ramp between 300°C and 700°C and increase kiln ventilation.

- If your primary focus is eliminating pinholes in your glaze: Ensure burnout is complete by extending the low-temperature phase of your firing before you approach glaze-melting temperatures.

- If your primary focus is ensuring consistent results with a new clay: Always program a cautious, slow ramp with plenty of ventilation through the burnout window for your test firings.

Mastering the carbon burnout phase is fundamental to taking control of your firing outcomes.

Summary Table:

| Aspect | Key Information |

|---|---|

| Process Name | Carbon Burnout / Oxidation |

| Temperature Range | 300°C to 700°C (572°F to 1292°F) |

| Critical Factor | Steady supply of oxygen |

| Common Defects | Black coring, bloating, glaze pinholes |

| Key Strategy | Slow ramp rate (60-80°C/hour) & good ventilation |

Achieve flawless ceramic firings with expert equipment and support from KINTEK!

Mastering the delicate carbon burnout phase is crucial for strong, defect-free results. KINTEK specializes in providing the reliable lab equipment and consumables—from precisely controlled kilns to effective ventilation systems—that your laboratory needs to ensure consistent success.

Let us help you optimize your firing process. Contact our experts today to discuss your specific laboratory requirements and discover the right solutions for you.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the process of thermal pyrolysis? A Step-by-Step Guide to Chemical Recycling

- What are the disadvantages of rotary kiln incinerator? High Costs and Operational Complexities

- Can you restore activated carbon? Understanding the Industrial Reactivation Process

- What does pyrolysis do to biochar? It's the Process That Creates and Defines It

- Why are rotary kiln reactors widely utilized for large-scale biomass torrefaction? Optimize Your Thermal Processing

- What is a fluidized bed chemical reaction? A Guide to Superior Heat Transfer & Continuous Processing

- How does a pyrolysis reactor work? A Guide to Controlled Thermal Decomposition

- What is the regeneration of carbon? Restore Your Spent Activated Carbon for Reuse