Simply put, heat kills microorganisms by permanently damaging their essential proteins. This process, known as denaturation, disrupts the proteins' structure and function, much like cooking an egg turns the white from a clear liquid into an opaque solid. Once critical proteins are denatured, the microorganism's cellular machinery breaks down, and it can no longer survive or reproduce.

The core principle is that heat transfers energy into a microorganism, causing its vital proteins and enzymes to unfold and lose their shape. This irreversible damage is lethal, making heat one of the most reliable and widely used methods for sterilization.

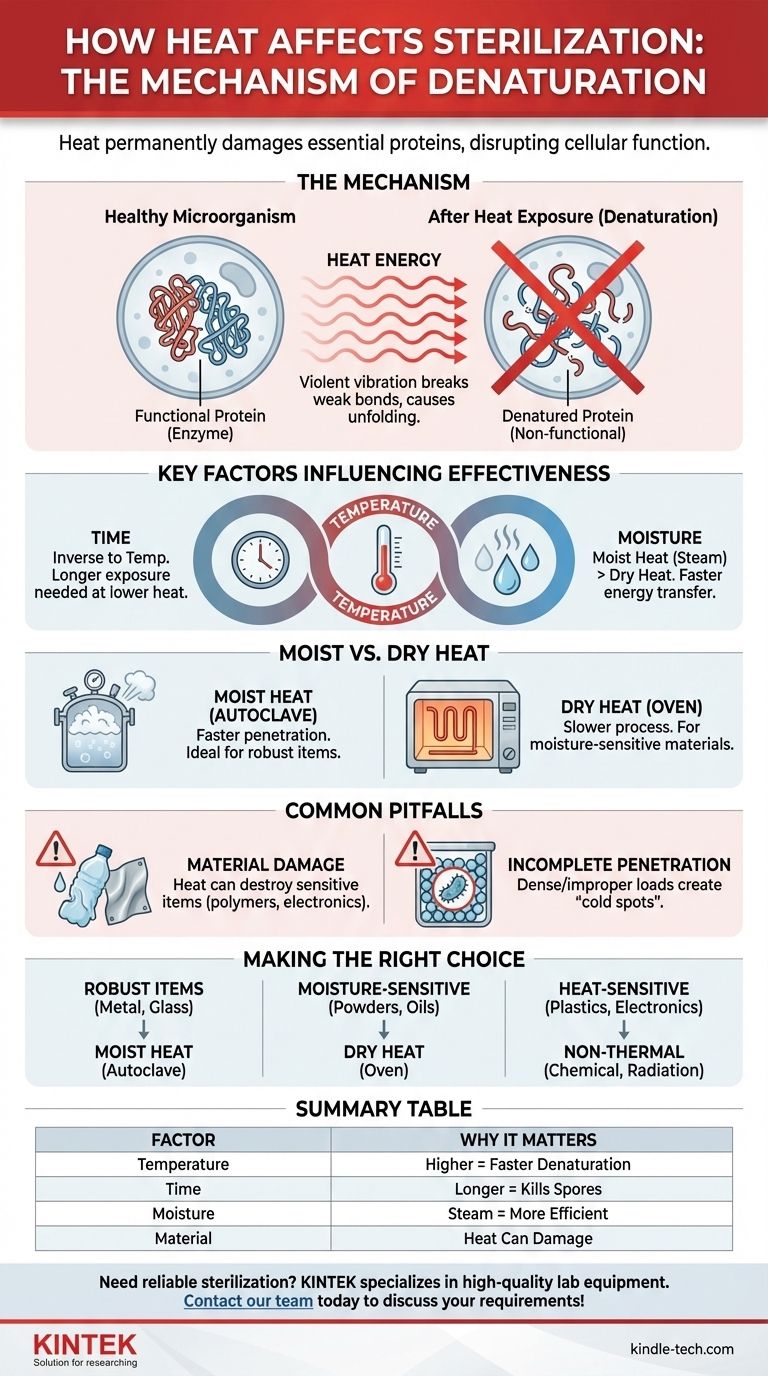

The Mechanism of Thermal Sterilization

To understand why heat is so effective, you have to look at the molecular level. A microorganism is a complex system that relies on thousands of precisely shaped proteins to function.

The Critical Role of Proteins

Proteins are the workhorses of any cell. They are responsible for everything from providing structural integrity to catalyzing the chemical reactions necessary for life (as enzymes).

A protein's function is entirely dependent on its unique, complex three-dimensional shape.

Denaturation: The Point of No Return

Heat introduces energy that causes the atoms within the protein to vibrate violently. This vibration breaks the weak bonds that hold the protein in its specific functional shape.

The protein unravels and loses its structure in a process called denaturation. This damage is almost always permanent.

Once a cell's essential proteins and enzymes are denatured, it can no longer metabolize, repair itself, or replicate. The cell is effectively dead.

Key Factors Influencing Effectiveness

Sterilization isn't just about turning up the heat; it's a carefully controlled process where several factors determine success or failure.

Time and Temperature

There is an inverse relationship between time and temperature. Higher temperatures can achieve sterilization in a much shorter period.

Conversely, lower temperatures require a significantly longer exposure time to ensure all microorganisms, including resilient spores, are eliminated.

Moist Heat vs. Dry Heat

The presence of water dramatically impacts efficiency. Moist heat (steam) is far more effective at sterilization than dry heat.

Water molecules help to transfer heat energy more efficiently into the cells and play a direct role in breaking the bonds within proteins, accelerating denaturation. This is why an autoclave, which uses pressurized steam, is a gold standard in medical and laboratory settings.

Common Pitfalls and Limitations

While powerful, heat sterilization is not a universal solution. Its primary limitation is the potential for collateral damage to the item being treated.

Damage to Materials

The very energy that destroys microbes can also destroy the object you are trying to sterilize. High temperatures can melt plastics, warp delicate instruments, or degrade sensitive chemical compounds.

This makes heat sterilization unsuitable for many polymers, electronics, and certain pharmaceuticals.

Incomplete Penetration

For sterilization to be effective, the heat must penetrate the entire object and reach every surface. Dense or improperly packaged items may have "cold spots" where microorganisms can survive.

This is why proper loading of an autoclave or sterilizer is critical to ensure steam or hot air can circulate freely.

Making the Right Choice for Your Application

Selecting the correct sterilization method requires balancing effectiveness against the nature of the material being sterilized.

- If your primary focus is sterilizing robust, heat-resistant items (like metal surgical tools or glassware): Moist heat sterilization via an autoclave is the fastest and most reliable method.

- If your primary focus is sterilizing materials sensitive to moisture (like powders, oils, or some metal instruments prone to rust): Dry heat sterilization is the appropriate choice, but you must account for longer cycle times and higher temperatures.

- If your primary focus is sterilizing heat-sensitive items (like most plastics, fiber optics, or electronics): You must use non-thermal methods such as chemical sterilization (ethylene oxide), radiation, or filtration.

Ultimately, understanding the mechanism of heat sterilization empowers you to apply it effectively and to recognize precisely when it is not the right tool for the job.

Summary Table:

| Factor | Why It Matters |

|---|---|

| Temperature | Higher temperatures cause faster, more effective protein denaturation. |

| Time | Longer exposure ensures all microorganisms, including spores, are killed. |

| Moisture | Steam (moist heat) transfers energy more efficiently than dry heat. |

| Material | Heat can damage sensitive items like plastics or electronics. |

Need a reliable sterilization solution for your lab? The right equipment is critical for effective and safe sterilization. KINTEK specializes in high-quality lab equipment, including autoclaves for moist heat sterilization and ovens for dry heat processes. Our experts can help you select the perfect system to meet your specific application needs, ensuring both efficacy and material compatibility. Contact our team today to discuss your laboratory's sterilization requirements!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

People Also Ask

- Can an autoclave reach temps as high as 121 degrees Celsius? The Definitive Guide to Steam Sterilization

- Why must autoclaving be done at 121°C and 15 psi? The Science Behind Guaranteed Sterilization

- What is the temperature used for autoclaving of microorganisms? Achieve Reliable Sterilization in Your Lab

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What are the key parameters for ensuring safe autoclave decontamination? Master Bio-Hazardous Waste Safety

- Why is a 24-hour hydrothermal treatment in an autoclave necessary for BMO nanosheets? Unlock Superior Photocatalysis

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What are the three components of autoclaving? Temperature, Pressure, and Time