In short, plasma is formed in a sputtering system by applying a high voltage between two electrodes within a low-pressure gas, typically Argon. This electric field accelerates free electrons, which then collide with and strip electrons from the gas atoms in a process called ionization, creating a self-sustaining environment of positive ions and free electrons.

Plasma is not merely a byproduct of the sputtering process; it is the active tool. By applying an electric field to a gas, you transform it from a neutral, passive substance into an energized, conductive state of matter specifically engineered to physically bombard a target.

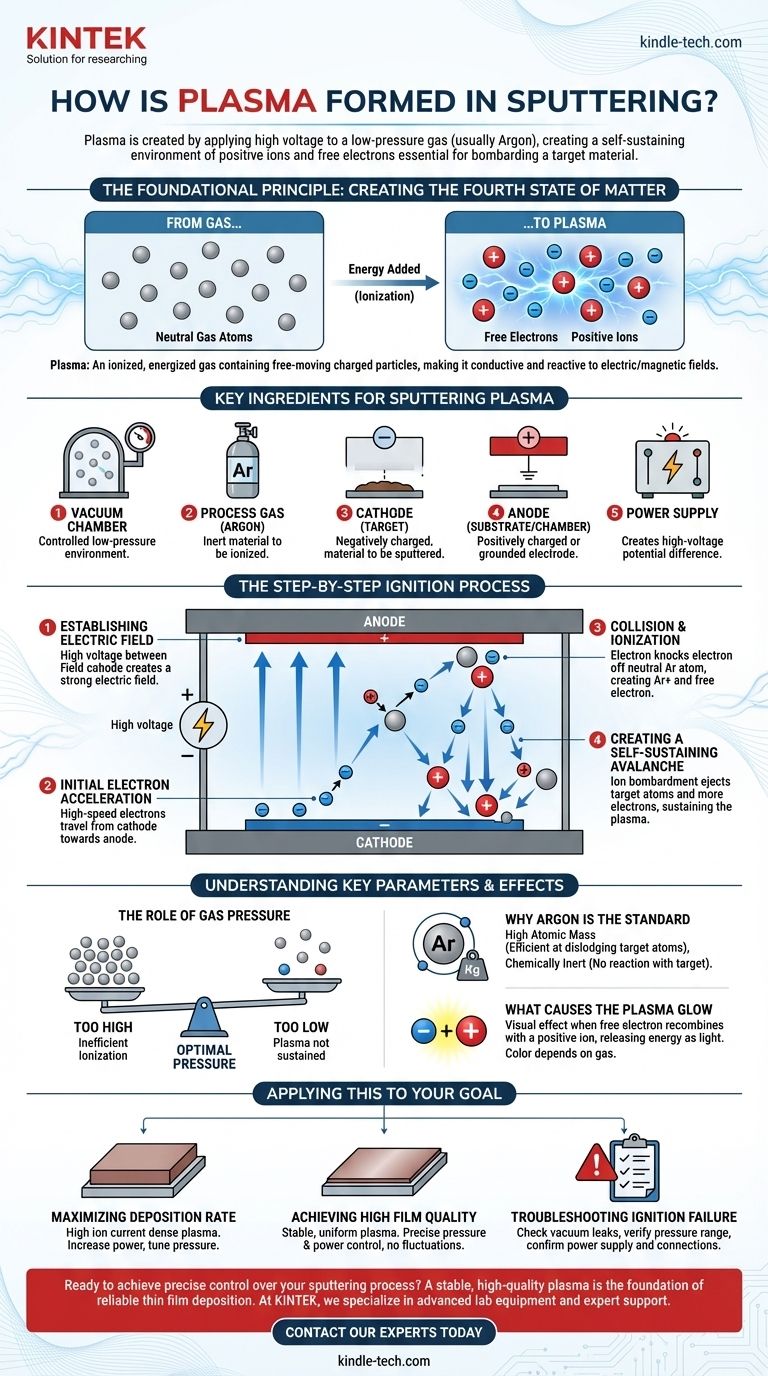

The Foundational Principle: Creating the Fourth State of Matter

To understand how plasma is generated in a sputtering chamber, we must first recognize what it is. Plasma is often called the fourth state of matter, a step beyond gas.

From Gas to Plasma

When sufficient energy is added to a gas, its atoms or molecules are broken apart. This process, called ionization, separates neutral gas atoms into two components: positively charged ions and negatively charged free electrons.

The resulting energized, ionized gas is plasma. Because it contains free-moving charged particles, it is electrically conductive and reacts strongly to electric and magnetic fields.

The Key Ingredients for Sputtering Plasma

Generating a stable plasma for sputtering requires a precise environment and a few key components working together.

- A Vacuum Chamber: The entire process must occur at a very low pressure to control the gas composition and allow particles to travel freely.

- A Process Gas: An inert gas, most commonly Argon (Ar), is introduced into the chamber. It serves as the material to be ionized.

- A Cathode: This is a negatively charged electrode where the target material—the material you want to deposit—is mounted.

- An Anode: This is a positively charged or grounded electrode, often comprising the chamber walls and the substrate holder.

- A Power Supply: This creates the high-voltage potential difference between the cathode and the anode.

The Step-by-Step Ignition Process

The creation of plasma is a rapid chain reaction, but it follows a clear sequence of events initiated by the electric field.

1. Establishing the Electric Field

First, a high DC or RF voltage is applied between the cathode and the anode. This creates a strong electric field throughout the low-pressure gas in the chamber.

2. The Initial Electron Acceleration

There are always a few stray electrons present in the chamber. The powerful electric field immediately accelerates these free electrons away from the negative cathode and towards the positive anode.

3. Collision and Ionization

As these high-speed electrons travel through the chamber, they collide with neutral Argon gas atoms. If an electron has enough energy, it will knock an electron off the Argon atom it hits.

This single collision event transforms one neutral Argon atom into two new particles: a positively charged Argon ion (Ar+) and another free electron.

4. Creating a Self-Sustaining Avalanche

This process creates a cascade. The original electron and the newly freed electron are both accelerated by the electric field, leading to more collisions and more ionization.

Simultaneously, the newly created positive Argon ions are accelerated in the opposite direction—directly toward the negatively charged cathode (the target). The high-energy bombardment of these ions onto the target is what ejects, or "sputters," the target atoms, which is the primary goal of the process. This bombardment also releases more electrons, ensuring the plasma is self-sustaining.

Understanding Key Parameters and Effects

The characteristics of your plasma directly impact the quality and rate of your deposition. Understanding the variables gives you control over the outcome.

The Role of Gas Pressure

The pressure of the process gas is a critical balancing act.

- If pressure is too high, an electron cannot travel far enough to gain sufficient energy before it collides with a gas atom. This leads to inefficient ionization.

- If pressure is too low, there are not enough gas atoms for electrons to collide with, and the plasma cannot be sustained.

Why Argon is the Standard

Argon is the most common choice for sputtering plasma for two main reasons. First, it is chemically inert, so it will not react with the target material. Second, it has a relatively high atomic mass, which makes its ions more effective at dislodging atoms from the target upon impact compared to lighter inert gases like Helium.

What Causes the Plasma Glow

The characteristic glow of a sputtering plasma is a visual side effect of the process. It occurs when a free electron loses energy and recombines with a positive ion. To return to a lower energy state, the particle pair releases the excess energy in the form of a photon of light. The color of the glow is specific to the type of gas being used.

Applying This to Your Goal

A stable, well-understood plasma is the foundation of a repeatable sputtering process. How you optimize your plasma depends entirely on your objective.

- If your primary focus is maximizing deposition rate: You need a dense plasma with a high ion current. This is achieved by increasing the power to the cathode and carefully tuning the gas pressure to maximize the ionization efficiency.

- If your primary focus is achieving high film quality: You need a stable and uniform plasma. This requires precise control of gas pressure and power, ensuring there are no fluctuations that could create defects or non-uniformity in your thin film.

- If you are troubleshooting a failure to ignite plasma: Your problem lies with one of the core ingredients. Check for vacuum leaks, verify your gas pressure is in the correct range, and confirm your power supply and electrical connections to the cathode and anode are functioning correctly.

Ultimately, controlling the sputtering process begins with mastering the generation and sustainment of the plasma itself.

Summary Table:

| Key Component | Role in Plasma Formation |

|---|---|

| Vacuum Chamber | Provides a low-pressure environment for controlled particle travel. |

| Process Gas (Argon) | The inert gas that is ionized to create the plasma. |

| Cathode (Target) | Negatively charged electrode; site of ion bombardment and sputtering. |

| Anode (Substrate/Chamber) | Positively charged electrode that attracts electrons. |

| High Voltage Power Supply | Creates the electric field that accelerates electrons to initiate ionization. |

Ready to achieve precise control over your sputtering process?

A stable, high-quality plasma is the foundation of reliable thin film deposition. At KINTEK, we specialize in providing the advanced lab equipment and expert support you need to master your sputtering applications.

Whether your goal is maximizing deposition rate or ensuring impeccable film quality, our range of sputtering systems and consumables is designed for performance and repeatability.

Contact our experts today to discuss how we can help you optimize your plasma process and achieve your research and production goals.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition