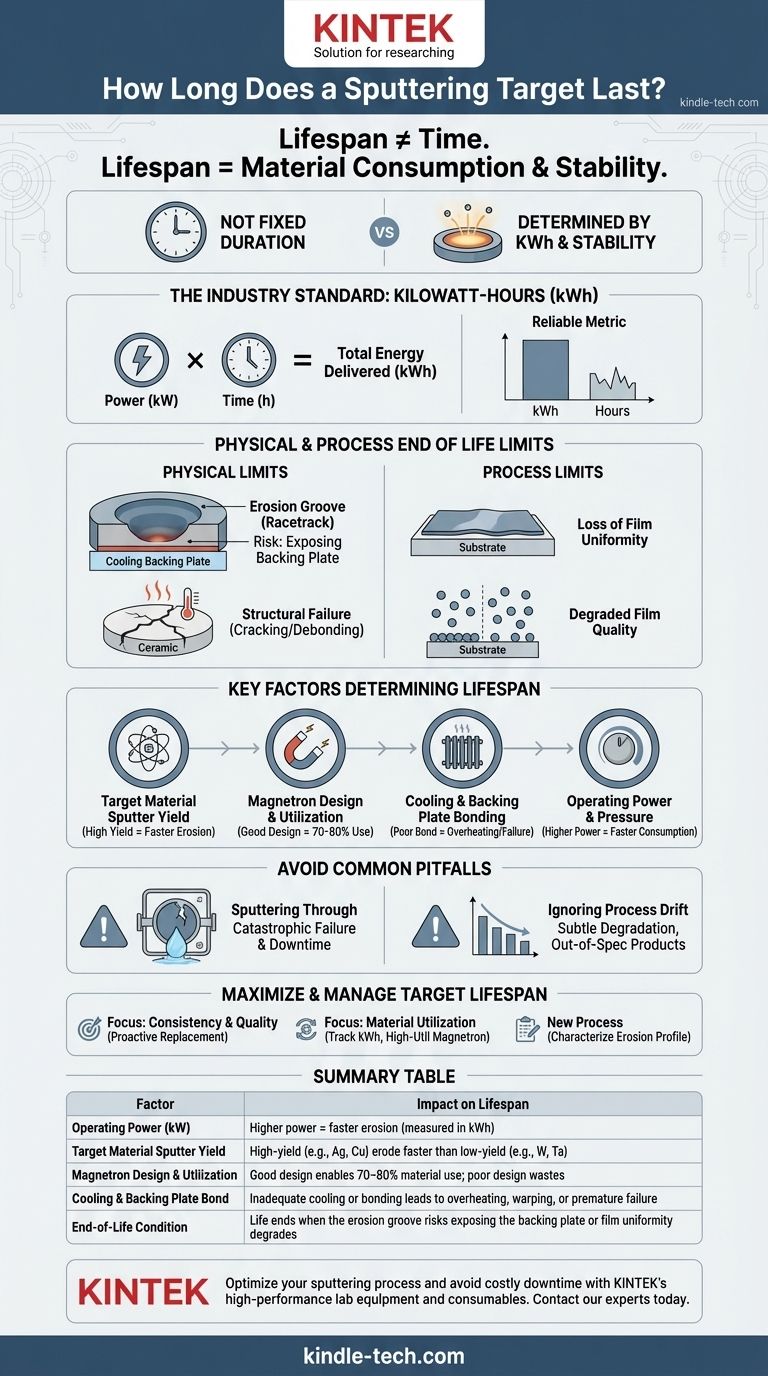

The lifespan of a sputtering target is not a fixed duration but is instead determined by the total amount of material consumed and its impact on process stability. Its usable life is typically measured in kilowatt-hours (kWh) and ends when the target can no longer produce a stable plasma or a uniform thin film, which often occurs long before the material is fully depleted.

A sputtering target's true "end of life" is a technical limit, not a time limit. It's reached when physical erosion compromises the cooling backing plate or when changes in the erosion profile degrade the quality and uniformity of your deposited films.

What 'End of Life' Really Means for a Sputtering Target

To manage a sputtering process effectively, you must shift your thinking from "how many hours does it last" to "what is its usable material limit." This distinction is critical for both process control and safety.

The Problem with Measuring in Hours

A target's erosion rate is directly proportional to the power applied. Running a process at 5 kW will consume a target twice as fast as running it at 2.5 kW. Therefore, time is a highly variable and unreliable metric for lifespan.

The Industry Standard: Kilowatt-Hours (kWh)

The most reliable way to track target usage is in kilowatt-hours (kWh). This metric combines power and time (Power [kW] x Time [h]), providing a consistent measure of the total energy delivered to the target, which correlates directly to the amount of material sputtered.

Physical Limit 1: The Erosion Groove

The magnets in the cathode (magnetron) confine the plasma to a specific area on the target face, creating an erosion groove or "racetrack." The target's life is over when this groove becomes so deep that it risks exposing or damaging the backing plate it's bonded to.

Physical Limit 2: Structural Failure

Brittle materials, such as ceramics, are susceptible to thermal stress. The constant heating from plasma bombardment and cooling from the backing plate can cause them to crack or debond, ending their life prematurely, regardless of the amount of material remaining.

Process Limit: Loss of Film Uniformity

As the erosion groove deepens, the geometry of the target surface changes. This alters the electric field and the distribution of sputtered atoms, which can degrade the thickness uniformity of the film being deposited on your substrates. At this point, the target is no longer useful for its intended application, even if it is physically intact.

Key Factors That Determine Target Lifespan

Several interconnected variables control how quickly a target reaches its end-of-life condition. Understanding these allows for better process planning and optimization.

Target Material and Sputter Yield

Different materials erode at different rates under the same conditions. A material's sputter yield—the number of atoms ejected per incident ion—is a primary factor. For example, silver and copper have very high sputter yields and erode quickly, while materials like tungsten or tantalum erode much more slowly.

Magnetron Design and Utilization

The design of the magnetron's magnetic pack is crucial. A well-designed magnetron creates a wider, more uniform erosion groove, leading to higher target material utilization (often 70-80%). A poorly designed one can create a deep, narrow groove, wasting material and leading to utilization as low as 20-30%.

Cooling and Backing Plate Bonding

Sputtering is an inefficient process that generates immense heat. The target must be bonded (typically with indium) to a water-cooled copper backing plate to dissipate this heat. If the bond is poor or cooling is insufficient, the target will overheat, potentially warping, cracking, or even melting.

Operating Power and Pressure

Higher power density increases the sputtering rate, reducing the target's life in terms of clock hours. Similarly, the operating gas pressure can influence plasma density and the shape of the erosion profile, subtly affecting how efficiently the material is used.

Understanding the Trade-offs and Common Pitfalls

Maximizing target life is a balance between material cost, process stability, and the risk of catastrophic failure.

The Danger of Sputtering Through

The single most critical mistake is trying to use every last gram of material. If the erosion groove reaches the backing plate, you risk sputtering the plate material (usually copper) into your film. Far worse, you can breach the plate, causing a water leak into your high-vacuum chamber, which can destroy the cathode and lead to catastrophic, expensive downtime.

Ignoring Subtle Process Drift

The decline in target performance is often gradual. Engineers may not notice a slow drift in film uniformity or other properties from run to run. The target's "process life" can end long before its physical life if these subtle changes are not monitored, resulting in out-of-spec products.

The True Cost: Downtime vs. Material

The cost of a new sputtering target is almost always insignificant compared to the cost of unplanned equipment downtime or a scrapped batch of high-value products. Proactive, scheduled target replacement is a cornerstone of a well-managed deposition process.

How to Manage and Maximize Target Lifespan

Your approach to target management should align directly with your operational priorities.

- If your primary focus is process consistency and quality: Proactively replace targets based on a pre-determined kWh limit or as soon as you detect a deviation in film properties.

- If your primary focus is maximizing material utilization: Invest in high-utilization magnetron designs and use a reliable kWh meter to track consumption, replacing the target just before it reaches its known physical limit.

- If you are developing a new process: Carefully characterize the target's erosion profile over its first life cycle to establish a safe and reliable kWh endpoint for all future replacements.

Ultimately, managing a sputtering target effectively is about ensuring the predictability and stability of your entire deposition process.

Summary Table:

| Key Factor | Impact on Target Lifespan |

|---|---|

| Operating Power (kW) | Higher power = faster erosion (measured in kWh). |

| Target Material Sputter Yield | High-yield materials (e.g., Ag, Cu) erode faster than low-yield ones (e.g., W, Ta). |

| Magnetron Design & Utilization | Good design enables 70-80% material use; poor design can waste 70-80% of the target. |

| Cooling & Backing Plate Bond | Inadequate cooling or bonding leads to overheating, warping, or premature failure. |

| End-of-Life Condition | Life ends when the erosion groove risks exposing the backing plate or film uniformity degrades. |

Optimize your sputtering process and avoid costly downtime. The lifespan of your sputtering target is critical to your lab's productivity and the quality of your thin films. KINTEK specializes in high-performance lab equipment and consumables, including sputtering targets and magnetrons designed for maximum material utilization and process stability. Let our experts help you select the right targets and implement best practices for your specific application. Contact KINTEK today to discuss your laboratory needs and ensure consistent, high-quality results.

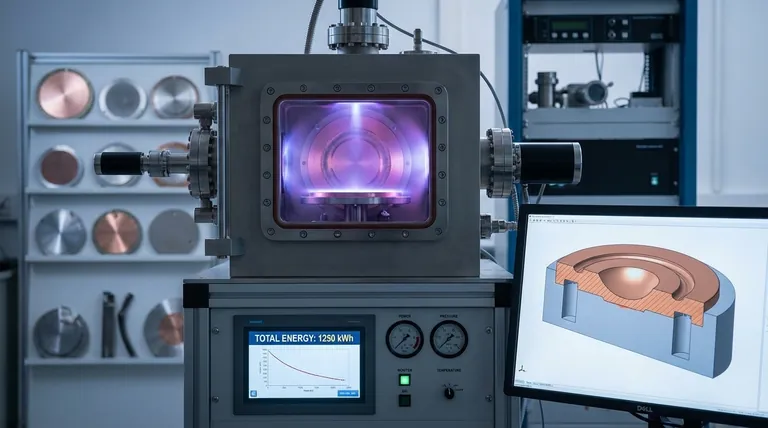

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Horizontal Autoclave Steam Sterilizer Lab Microcomputer Sterilizer

People Also Ask

- Why is vacuum needed in an evaporator? To Protect Heat-Sensitive Materials and Boost Efficiency

- What is the purpose of using an aluminum silicate fiber bed? Unlock True Kinetic Data for Your TGA Experiments

- Why are quartz sleeves utilized to protect thermocouples during high-temperature corrosion testing? Ensure Data Accuracy

- Why must Sm–Co magnet recovery be in an argon glove box? Ensure 1ppm Oxygen & Moisture Control

- What is the lining material for furnace? A Guide to High-Temperature Refractories

- What are the different drive types for Rotary Vane Vacuum Pumps? Choose the Best Drive for Performance

- What is the primary purpose of a cold trap in precision gas measurement? Ensure Data Purity with KINTEK Solutions

- Why are zirconia grinding balls preferred for milling battery cathode or electrolyte powders? Achieve High Purity