Under ideal conditions, the core material in fiberglass insulation can last for 80 to 100 years. However, its actual effective lifespan is rarely that long. The ability of insulation to resist heat flow depends entirely on its condition, which can be easily compromised by common household issues like moisture, pests, or physical compression.

The key takeaway is not the age of the insulation, but its current condition. While the glass fibers themselves are incredibly durable, the insulation's performance hinges on its ability to trap air, a quality that is easily degraded long before the material itself breaks down.

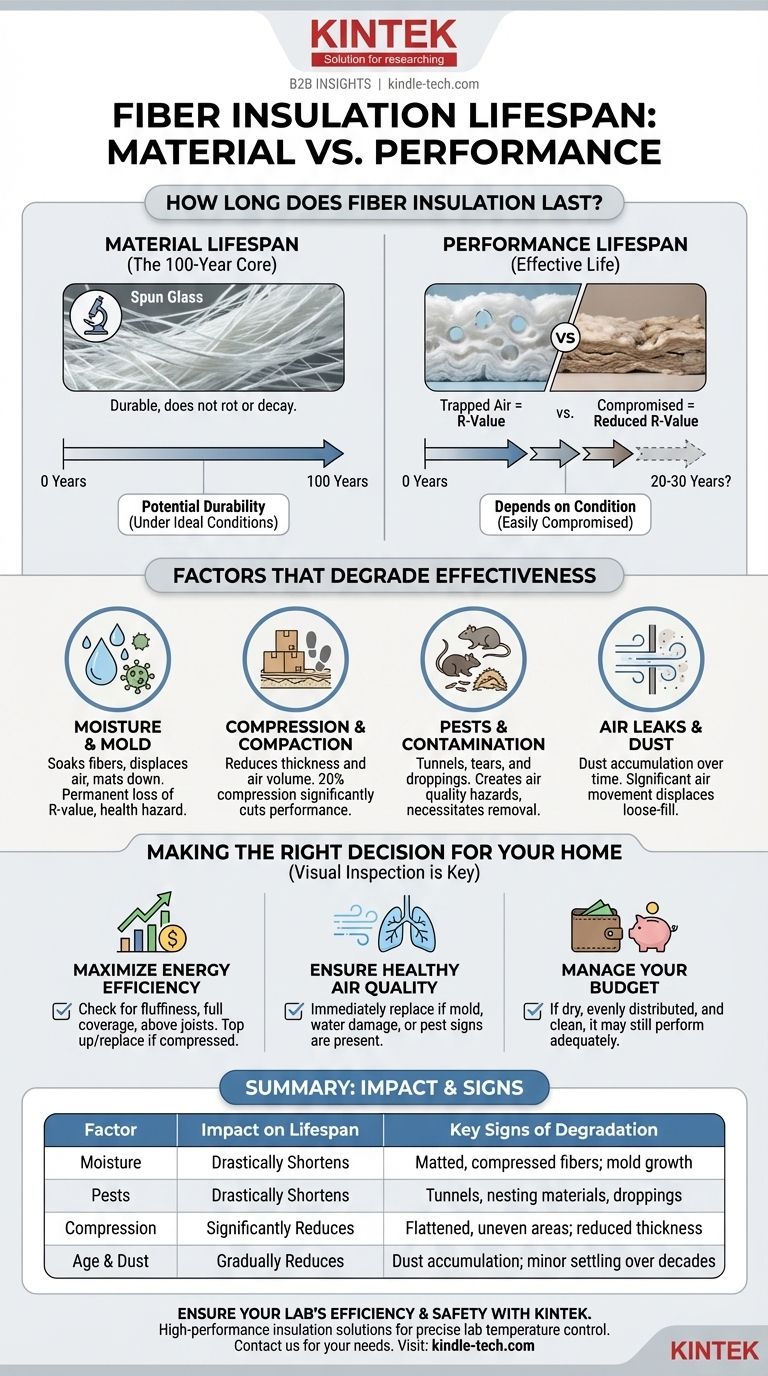

Material Lifespan vs. Performance Lifespan

To understand when insulation needs replacing, we must distinguish between the durability of the material and the effectiveness of its performance.

The 100-Year Material

Fiberglass is, at its core, spun glass. It does not rot, decay, or decompose in the same way organic materials do. In a controlled, sterile environment, it can maintain its physical structure for many decades.

Performance Depends on Trapped Air

Insulation doesn't stop heat with its fibers; it stops heat by trapping countless tiny pockets of still air within those fibers. This trapped air is what gives insulation its R-value, or its resistance to heat flow.

Why Performance Fades

The effective life of your insulation ends when it can no longer trap air efficiently. Anything that reduces the volume of these air pockets directly reduces the R-value, regardless of the material's age.

Factors That Degrade Insulation's Effectiveness

Focusing on the age of your insulation is misleading. Instead, you should be looking for signs of damage from these common culprits, which are the true indicators of a shortened lifespan.

Moisture and Mold

Water is the primary enemy of fiber insulation. It soaks into the fibers, displaces the trapped air, and mats the material down. Once compressed by moisture, fiberglass rarely recovers its original thickness (or "loft"), causing a permanent loss of R-value. Chronic dampness also leads to mold and mildew growth.

Compression and Compaction

Storing boxes in an attic, foot traffic from maintenance work, or even the material's own weight over many decades can compress insulation. A 20% loss in thickness can lead to a significant loss in performance.

Pests and Contamination

Rodents, birds, and insects often nest in insulation. They create tunnels, tear the material apart, and compress it significantly. Their droppings and waste also create serious air quality hazards, necessitating complete removal.

Air Leaks and Dust

Poorly sealed attics or walls allow air to move through the insulation. This can lead to dust and dirt accumulating within the fibers over time, slightly reducing its effectiveness. More importantly, significant air movement can displace loose-fill insulation, creating bare spots that act as thermal bridges for heat to escape.

Making the Right Decision for Your Home

Your decision to replace or add insulation should be based on a visual inspection of its condition, not a number on a calendar.

- If your primary focus is maximizing energy efficiency: Check that insulation is fluffy, fills the entire cavity, and sits well above the height of your ceiling joists. If it's compressed or uneven, topping it up or replacing it will yield immediate savings.

- If your primary focus is healthy air quality: Immediately replace any insulation that shows signs of mold, significant water damage, or pest contamination.

- If your primary focus is managing your budget: If your insulation is dry, evenly distributed, and free of contaminants, it is likely still performing adequately and does not require urgent replacement.

Ultimately, evaluating your insulation's condition is the most reliable way to ensure your home remains comfortable and efficient.

Summary Table:

| Factor | Impact on Lifespan | Key Signs of Degradation |

|---|---|---|

| Moisture | Drastically Shortens | Matted, compressed fibers; mold growth |

| Pests | Drastically Shortens | Tunnels, nesting materials, droppings |

| Compression | Significantly Reduces | Flattened, uneven areas; reduced thickness |

| Age & Dust | Gradually Reduces | Dust accumulation; minor settling over decades |

Ensure your lab's thermal efficiency and safety with high-performance insulation solutions from KINTEK.

Just as proper insulation is critical for home energy efficiency and air quality, precise temperature control is non-negotiable in the laboratory. KINTEK specializes in durable, reliable lab equipment and consumables, including high-temperature furnaces and ovens that depend on superior insulation for accurate, consistent results.

If you're looking to optimize your lab's performance, manage energy costs, or need equipment that stands the test of time, our experts can help. Contact KINTEK today to discuss your specific laboratory needs and discover the right solutions for you.

Visual Guide

Related Products

- Copper Foam

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

People Also Ask

- How long should a heating element last? Maximize your oven's lifespan with these key insights.

- What happens to tungsten when heated? Discover Its Extreme Heat Resistance and Unique Properties

- Why are high-performance resistance heating elements required in pyrolysis? Ensure Precise Biomass Conversion

- What is special about tungsten? The Ultimate Metal for Extreme Heat & Wear Resistance

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What happens when tungsten is heated? Harnessing Extreme Heat for Demanding Applications

- What is the best substitute for tungsten? Choose the Right Material for Your Application

- Why do heating elements have high resistance? To Efficiently Convert Electricity into Heat