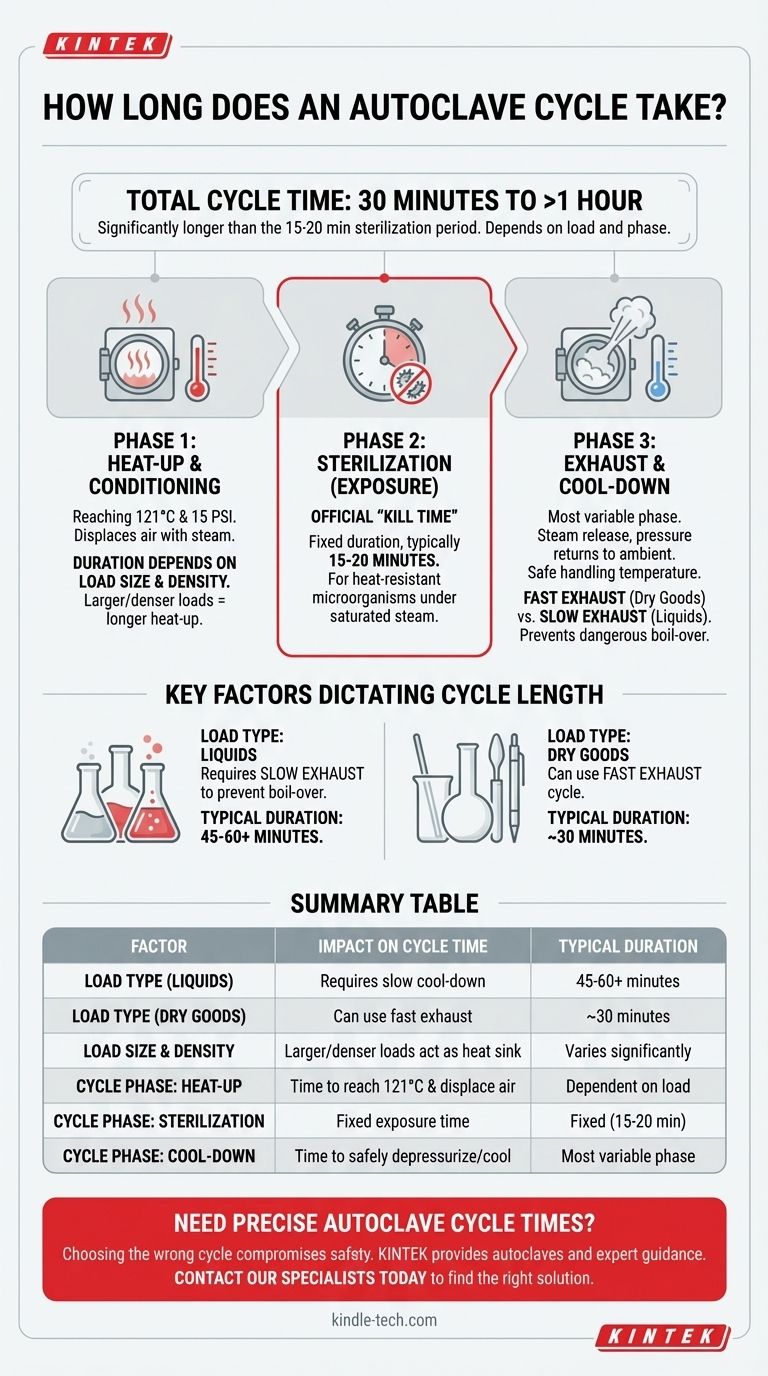

The total time for an autoclave cycle is significantly longer than the core sterilization period. While the actual sterilization exposure at 121°C is typically set for 15-20 minutes, a complete cycle from start to finish commonly ranges from 30 minutes to over an hour. This variation is not arbitrary; it is determined by the specific materials you are sterilizing and the distinct phases of the autoclave process.

The total cycle time is not a single number but the sum of three distinct phases: heat-up, sterilization, and cool-down. The duration of each phase—and therefore the total time—is dictated entirely by the size, density, and type of the load being processed.

The Anatomy of an Autoclave Cycle

To understand the total time, you must first understand that a cycle is composed of several sequential stages. The "15-minute" figure people often quote refers to only one of these parts.

Phase 1: Heat-Up (or Conditioning)

Before sterilization can begin, the chamber must reach the target temperature and pressure (e.g., 121°C and 15 PSI). This phase involves injecting steam to displace the cooler air.

The time required for this phase is highly dependent on the size and density of the load. A large, dense load acts as a heat sink, demanding more time and energy to bring everything to a uniform temperature.

Phase 2: Sterilization (or Exposure)

This is the official "kill time." Once the entire load has reached the target temperature, the cycle timer begins its countdown, typically 15 minutes.

This duration is the scientifically validated time required to kill heat-resistant microorganisms under saturated steam conditions. For very dense or large-volume loads, this phase may be programmed for longer to ensure full heat penetration.

Phase 3: Exhaust and Cool-Down

After sterilization, the steam is released, and the pressure returns to ambient levels. The load must then cool to a temperature that is safe to handle.

This phase is the most variable part of the cycle. The method of exhaust is chosen based on the load type and dramatically impacts the total time. A fast exhaust for dry goods is quick, while a slow exhaust for liquids is intentionally prolonged to prevent dangerous boil-over.

Key Factors That Dictate Cycle Length

The "it depends" answer becomes clear when you examine the variables that influence each phase of the cycle.

Load Size and Density

A small load of empty glassware will heat up and cool down much faster than a large, tightly packed bag of biological waste. The principle is simple: more mass requires more time for heat to penetrate and then dissipate.

Load Type: Liquids vs. Solids

This is the single most important factor. Sterilizing liquids requires a slow exhaust cycle to gradually lower the pressure, preventing the liquids from boiling violently inside their containers. This can add 20-30 minutes or more to the total cycle time compared to sterilizing solid instruments or empty glassware.

Autoclave Performance

The power of the autoclave's steam generator and the efficiency of its vacuum pumps (if equipped) also play a role. A modern, high-performance unit will generally complete heat-up and exhaust phases faster than an older or more basic model.

Common Pitfalls to Avoid

Understanding cycle time isn't just about scheduling; it's about ensuring safety and efficacy.

The Danger of Rushing a Cycle

Attempting to shorten a cycle is a critical error. Cutting the sterilization time results in non-sterile materials. Rushing the cool-down phase for liquids can cause glass to shatter or superheated liquid to erupt upon opening the door, posing a serious safety hazard.

Using the Wrong Cycle Type

Selecting a "fast exhaust" or "gravity" cycle for a liquid load is extremely dangerous. Conversely, using a "liquid" cycle for dry goods is inefficient and wastes time. Always match the programmed cycle to the physical contents of your load.

Making the Right Choice for Your Goal

Use the contents of your load to estimate the required time and select the correct cycle.

- If your primary focus is sterilizing liquids (e.g., media, buffers): Expect longer cycles (45-60+ minutes) and always use a designated "liquid" or "slow exhaust" setting to prevent boil-over.

- If your primary focus is sterilizing dry, hard goods (e.g., empty glassware, instruments): You can use faster "gravity" or "fast exhaust" cycles, which may take as little as 30 minutes.

- If your primary focus is sterilizing porous items or waste bags: A "pre-vacuum" cycle is often necessary to ensure steam penetrates the entire load, with times varying based on density but often falling in the 45-60 minute range.

Understanding these factors empowers you to not only predict cycle times but also ensure every run is both safe and effective.

Summary Table:

| Factor | Impact on Cycle Time | Typical Duration |

|---|---|---|

| Load Type (Liquids) | Requires slow cool-down to prevent boil-over | 45-60+ minutes |

| Load Type (Dry Goods) | Can use fast exhaust cycle | ~30 minutes |

| Load Size & Density | Larger, denser loads act as a heat sink, increasing time | Varies significantly |

| Cycle Phase: Heat-Up | Time to reach 121°C and displace air | Dependent on load |

| Cycle Phase: Sterilization | Fixed exposure time (e.g., 15-20 minutes) | Fixed duration |

| Cycle Phase: Cool-Down | Time to safely depressurize and cool | Most variable phase |

Need precise autoclave cycle times for your specific lab materials?

Choosing the wrong cycle can compromise sterilization or create safety hazards. KINTEK specializes in lab equipment and consumables, providing autoclaves and expert guidance to ensure your processes are both efficient and safe.

Contact our specialists today to discuss your laboratory's sterilization needs and find the right autoclave solution for your workflow.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Why is an autoclave or pressure cooker better than dry heat for sanitizing? Superior Sterilization with Steam

- What are the requirements for an autoclave machine? Achieve Sterile Confidence for Your Lab

- Why do we do 121 degree sterilization? The Science Behind Guaranteed Sterility

- What is the benefit of autoclave? Achieve Rapid, Reliable Sterilization for Your Lab

- What is the difference between autoclave types? Choose the Right Sterilizer for Your Lab

- What are the disadvantages of autoclaving? Protect Your Heat-Sensitive Materials and Ensure Safety

- How long should an autoclave cycle be? A Guide to Optimizing Sterilization Time

- How does a Teflon-lined stainless steel autoclave facilitate the hydrothermal synthesis of Co(OH)F nanowire precursors?