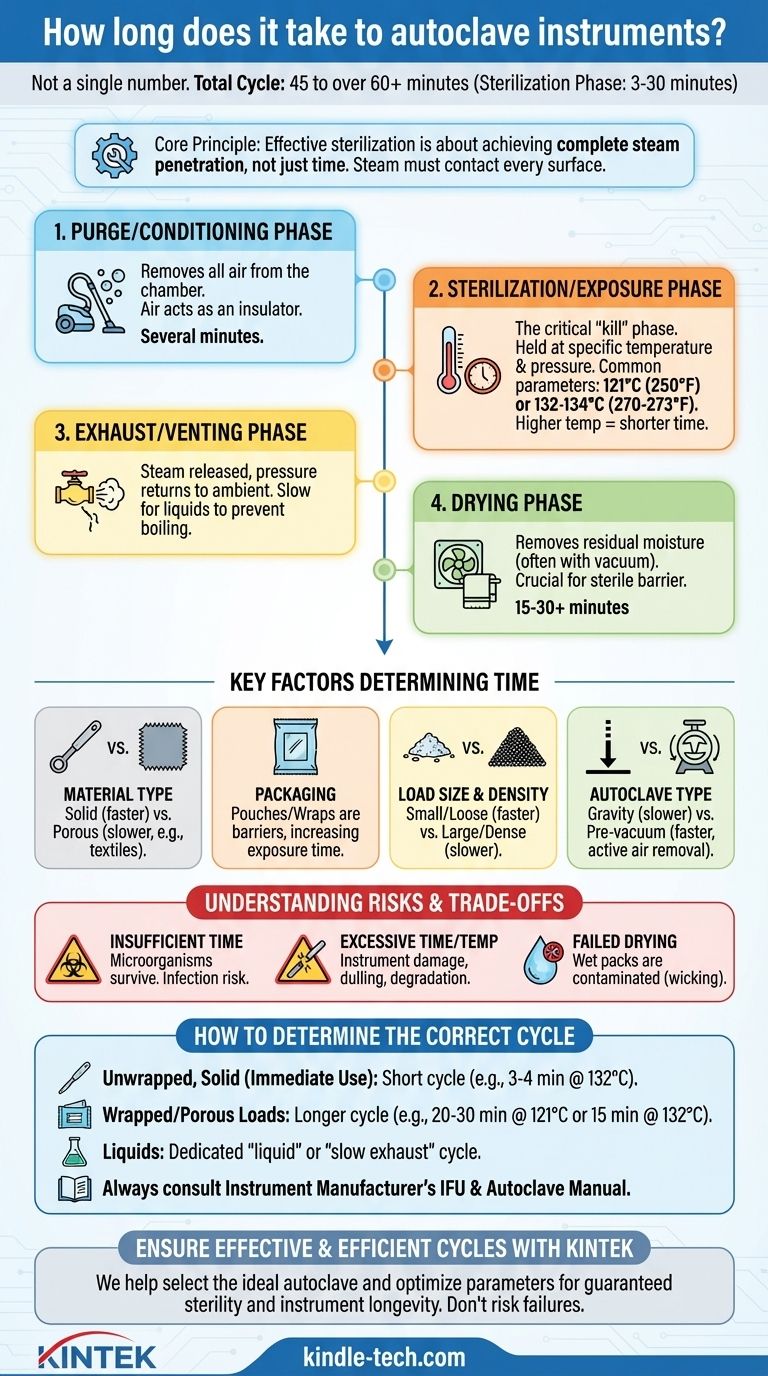

The time required to autoclave instruments is not a single number, but a range that depends heavily on the items being sterilized and the type of autoclave used. The actual sterilization phase—the time spent at the target temperature—typically lasts between 3 and 30 minutes. However, the total cycle time from start to finish is much longer, often ranging from 45 to over 60 minutes, to account for heating, pressure changes, and drying.

The core principle to understand is that effective sterilization isn't just about time; it's about achieving complete steam penetration. The "correct" duration is the time it takes for pressurized steam to contact every surface of the items in the load for the required period.

The Four Stages of an Autoclave Cycle

A common misconception is that the clock starts and stops with the sterilization phase. In reality, the total process involves four distinct stages, each contributing to the overall time.

1. Purge/Conditioning Phase

Before sterilization can begin, all air must be removed from the chamber. Air acts as an insulator and prevents steam from making direct contact with the instruments, which would lead to a sterilization failure. This phase can take several minutes.

2. Sterilization/Exposure Phase

This is the critical "kill" phase where the actual sterilization occurs. The load is held at a specific temperature and pressure for a prescribed duration.

Common parameters are 121°C (250°F) or 132-134°C (270-273°F). A higher temperature generally allows for a shorter exposure time.

3. Exhaust/Venting Phase

Once the exposure time is complete, the steam is released from the chamber. The pressure is slowly returned to ambient levels. For liquids, this phase must be very slow to prevent boiling over.

4. Drying Phase

This final, crucial stage removes residual moisture from the instrument packs. A vacuum is often pulled to flash-vaporize the water, ensuring the packs are completely dry. This can take 15-30 minutes or more.

Key Factors That Determine Sterilization Time

The duration of the sterilization phase is not arbitrary. It is determined by several factors that directly impact the ability of steam to penetrate the load.

The Type of Material

Solid, non-porous items like stainless steel surgical instruments require less time because steam can quickly contact their surfaces. Porous materials like textiles, gowns, or gauze require much longer cycles to ensure the steam penetrates deep into the fibers.

Packaging and Wrapping

Instruments are rarely sterilized loose. They are placed in pouches, cassettes, or wrapped in special sterilization fabric. Each layer presents a barrier that steam must pass through, increasing the necessary exposure time.

Load Size and Density

A small, loosely arranged load will sterilize much faster than a large, densely packed one. Think of it like cooking: a single potato bakes faster than a large, dense casserole. The steam must reach the most challenging point in the center of the load, which takes time.

Autoclave Type

Gravity displacement autoclaves rely on steam being lighter than air; as steam fills the chamber, it pushes the cooler, heavier air out through a drain. This is a slower, less efficient method of air removal.

Pre-vacuum (or dynamic air removal) autoclaves use a vacuum pump to actively remove air before introducing steam. This results in faster, more reliable steam penetration and allows for shorter overall cycle times, especially for porous loads.

Understanding the Trade-offs and Risks

Choosing the correct cycle is a matter of safety and equipment longevity. Both under- and over-processing carry significant risks.

The Danger of Insufficient Time

This is the most critical risk. If the cycle is too short or steam penetration is incomplete, microorganisms will survive. This results in non-sterile instruments that can cause severe patient infections.

The Risk of Excessive Time or Temperature

More is not always better. Repeatedly exposing instruments to excessive heat can dull sharp edges, weaken sensitive components, and degrade plastics and textiles. The goal is to achieve sterility with the minimum exposure necessary to preserve the life of the instrument.

The Critical Role of Drying

A pack that is wet or damp at the end of a cycle is considered contaminated. Moisture can act as a wick, allowing bacteria from the outside air to travel through the packaging material and compromise the sterile barrier. A failed drying phase means the entire load must be re-processed.

How to Determine the Correct Cycle for Your Needs

Your decision must be guided by manufacturer instructions and the specific load you are processing. Always default to the most conservative and safest option.

- If you are sterilizing unwrapped, solid metal instruments for immediate use: You can often use a very short cycle (e.g., 3-4 minutes at 132°C), but this is only for urgent, point-of-use situations and is not recommended for routine processing.

- If you are sterilizing wrapped instrument kits or porous loads: You must use a longer cycle (e.g., 20-30 minutes at 121°C or 15 minutes at 132°C) to ensure full steam penetration through all layers.

- If you are sterilizing liquids or laboratory media: You must use a dedicated "liquid" or "slow exhaust" cycle, which can significantly increase the total run time to prevent the liquids from boiling over during depressurization.

- If you are ever unsure: The definitive answer lies in the instrument manufacturer's Instructions for Use (IFU) and your autoclave's operating manual.

By understanding these core principles, you can move beyond simply asking "how long" and begin ensuring every cycle you run is both effective and safe.

Summary Table:

| Factor | Impact on Sterilization Time |

|---|---|

| Material Type | Porous loads (textiles) require longer cycles than solid instruments. |

| Packaging | Wrapped kits/pouches increase time needed for steam penetration. |

| Load Size/Density | Large, dense loads require significantly more time than small, loose ones. |

| Autoclave Type | Pre-vacuum cycles are faster than gravity displacement for porous loads. |

| Cycle Temperature | Higher temperatures (132-134°C) allow for shorter exposure times. |

Ensure Your Sterilization Cycles Are Both Effective and Efficient

Choosing the right autoclave and cycle parameters is critical for lab safety and instrument longevity. KINTEK specializes in providing reliable lab equipment and consumables tailored to your laboratory's specific sterilization needs.

We can help you:

- Select the ideal autoclave (gravity displacement or pre-vacuum) for your load types.

- Understand manufacturer IFUs to optimize cycle times and protect your instruments.

- Ensure complete steam penetration and proper drying for guaranteed sterility.

Don't risk sterilization failures or equipment damage. Let our experts provide the right solution for your lab.

Contact KINTEL today for a consultation to optimize your sterilization processes!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What are the three types of sterilizers? Choose the Right Method for Your Lab

- What is the function and limitation of chemical indicators in autoclave monitoring? Essential Sterilization Workflow Guide

- Why must AISI 321 stainless steel samples be treated in an autoclave? Ensure Sterile Precision in Blood Culture Tests

- What is the autoclaving process in microbiology? Ensure Sterile Results and Lab Safety

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- How do batch high-pressure autoclaves facilitate the catalytic hydrogenation of glucose? Boost Sorbitol Yield to 99%+

- What precautions should be taken during autoclave in laboratory? A Complete Safety Guide to Prevent Burns and Explosions

- Is autoclave a lab equipment? Essential Sterilization for Reliable Science